Rail for straight-curve transition section and production method of rail

A production method and transition section technology, applied in the direction of rails, rails, furnace types, etc., can solve the problems of rails prone to use defects, tread fatigue cracks, and low hardness of rails, so as to achieve easy popularization and application, improve service life, and reduce maintenance The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

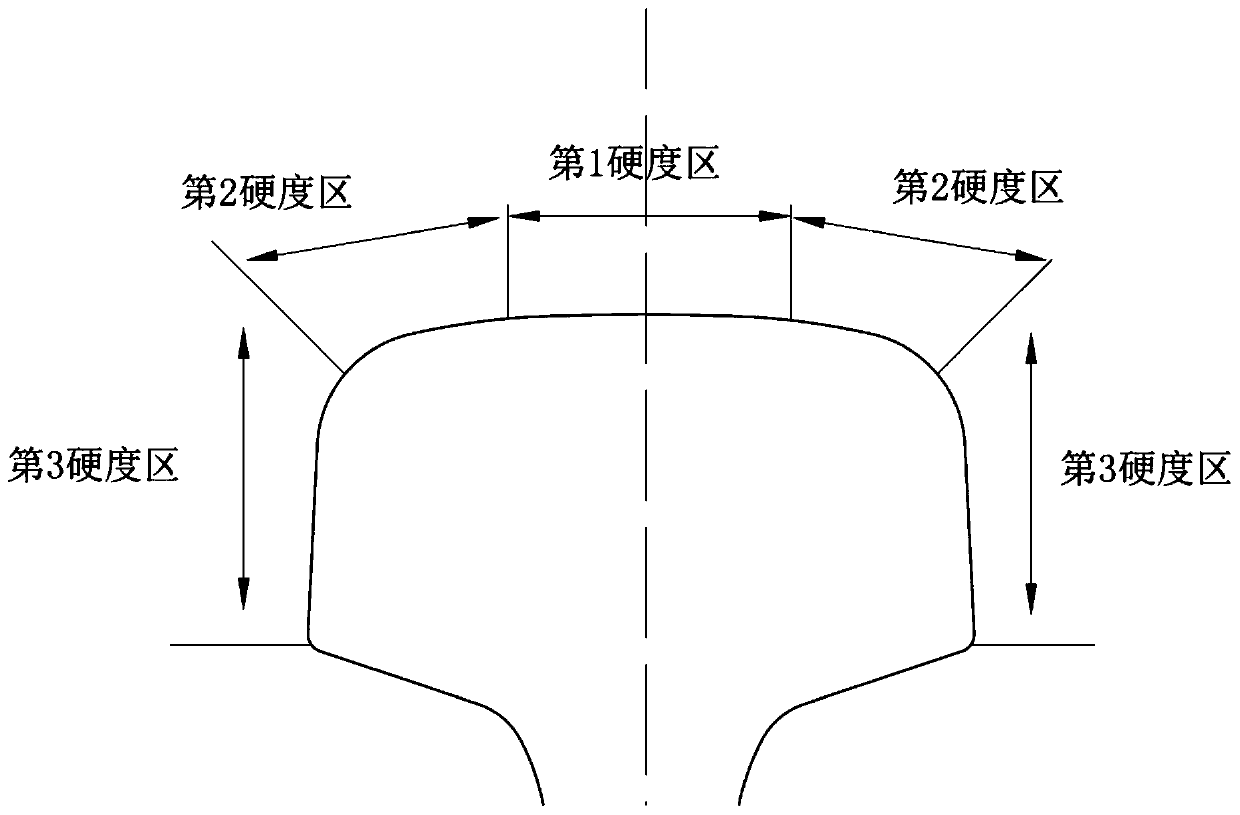

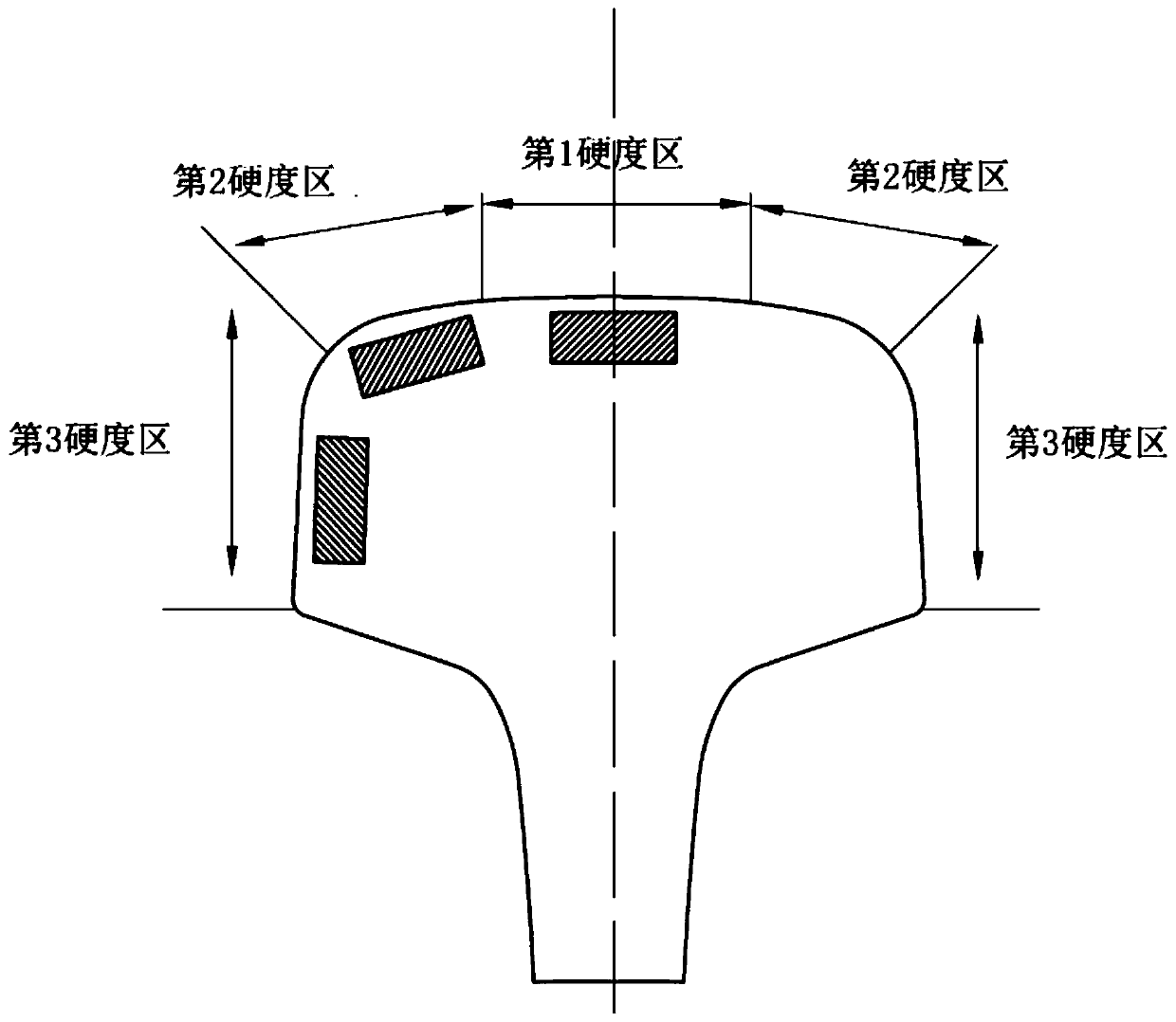

[0022] Such as figure 1 As shown, a steel rail for a straight-curve transition section includes a steel rail, and the area from the rail head to the lower jaw of the steel rail has three hardness zones, which are respectively the first hardness zone, the second hardness zone and the third hardness zone , wherein the first hardness zone is distributed in the middle of the rail head tread, the second hardness zone is distributed from the boundary of the first hardness zone to the rail angle, and the third hardness zone is distributed from the boundary of the second hardness zone to the lower jaw of the rail head, The Brinell hardness value of the first hardness zone is 305HB~340HB, the Brinell hardness value of the second hardness zone is 340HB~375HB, and the Brinell hardness value of the third hardness zone is 375HB~410HB, forming a certain hardness distribution gradient. 1, 2, 3 hardness zones are distributed on the whole rail along the longitudinal direction.

Embodiment 2

[0024] Such as figure 1 As shown, a steel rail for a straight-curve transition section includes a steel rail, and the area from the rail head to the lower jaw of the steel rail has three hardness zones, which are respectively the first hardness zone, the second hardness zone and the third hardness zone , wherein, the first hardness zone, the second hardness zone and the third hardness zone are distributed with the central axis of the cross-section of the rail head as a plane of symmetry, the first hardness zone is distributed in the middle of the tread of the rail head, and the second hardness zone The zone is distributed from the boundary of the first hardness zone to the position of the rail angle, and the third hardness zone is distributed from the boundary of the second hardness zone to the lower jaw of the rail head. The Brinell hardness value of the first hardness zone is 305HB~340HB, The Brinell hardness value is 340HB~375HB, and the Brinell hardness value of the third ...

Embodiment 3

[0027] Such as figure 1 As shown, a steel rail for a straight-curve transition section includes a steel rail, and the area from the rail head to the lower jaw of the steel rail has three hardness zones, which are respectively the first hardness zone, the second hardness zone and the third hardness zone , wherein, the first hardness zone, the second hardness zone and the third hardness zone are distributed with the central axis of the cross-section of the rail head as a plane of symmetry, the first hardness zone is distributed in the middle of the tread of the rail head, and the second hardness zone The zone is distributed from the boundary of the first hardness zone to the rail angle, and the third hardness zone is distributed from the boundary of the second hardness zone to the lower jaw of the rail head. The Brinell hardness value of the first hardness zone is 305HB~340HB, The Brinell hardness value is 340HB-375HB, and the Brinell hardness value of the third hardness zone is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com