Steering conveying device used for hardware fitting steel blocks

A technology for conveying devices and accessories, applied in the direction of conveyor objects, transportation and packaging, etc., which can solve problems such as large space, space waste, and long cooling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

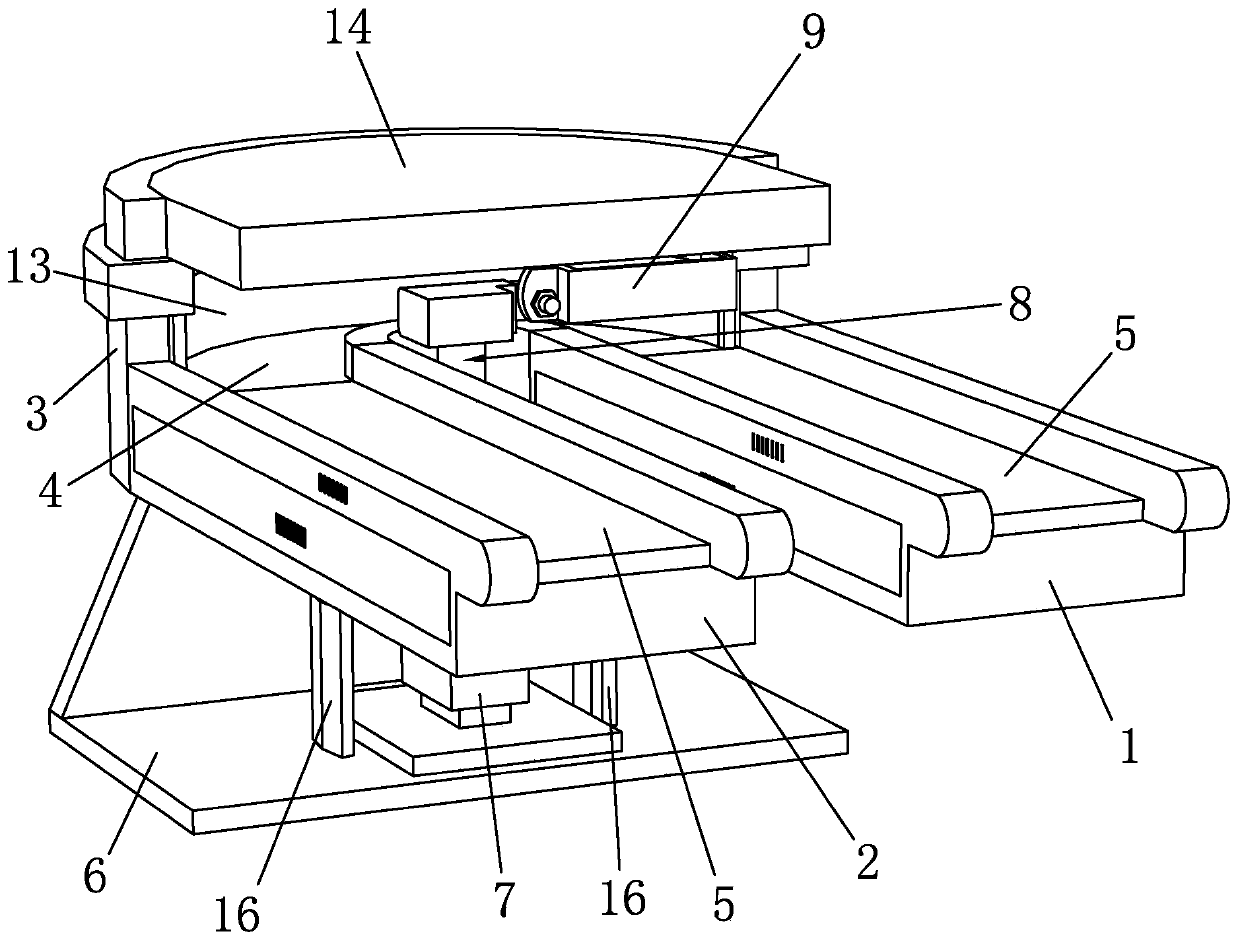

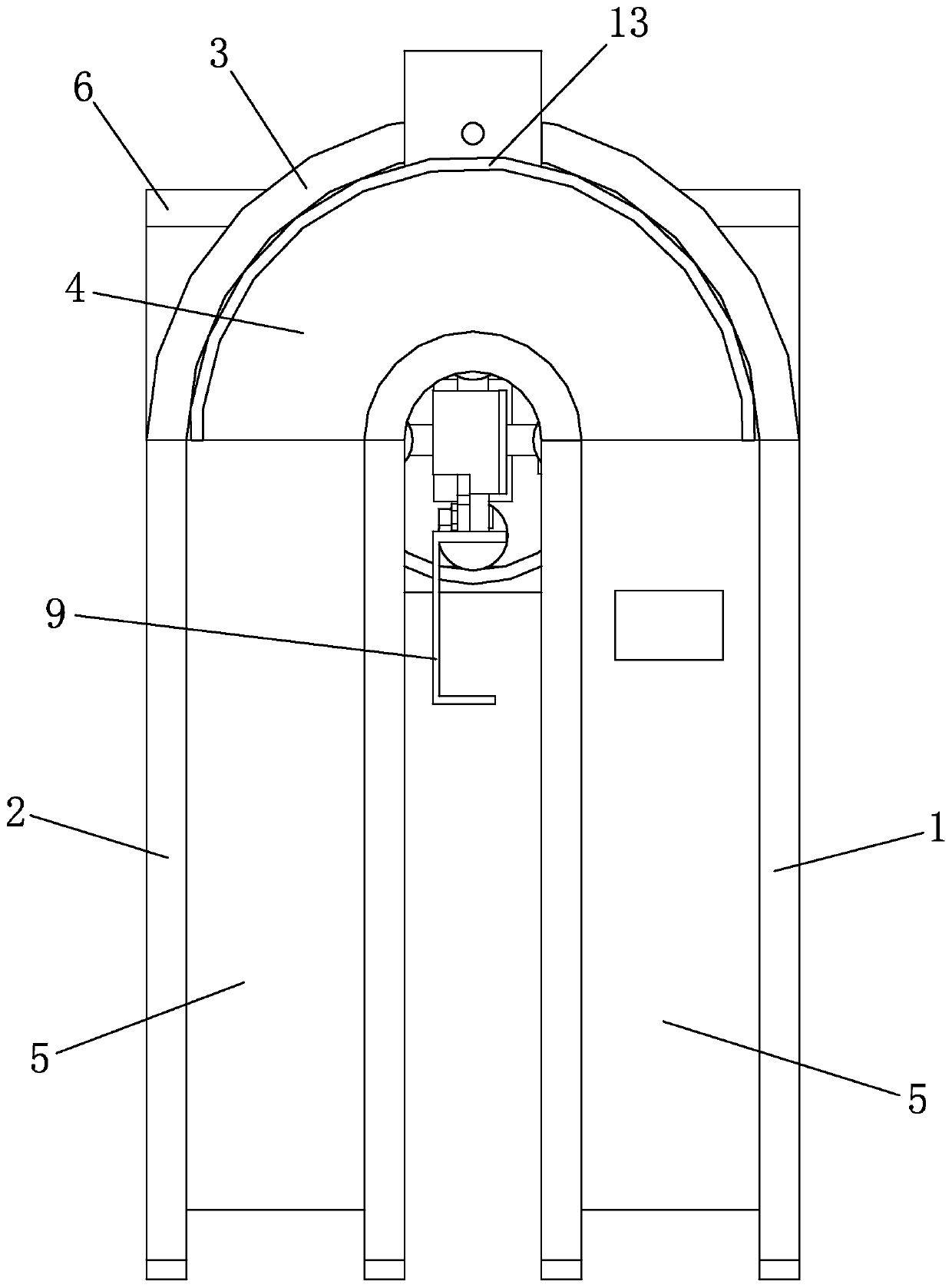

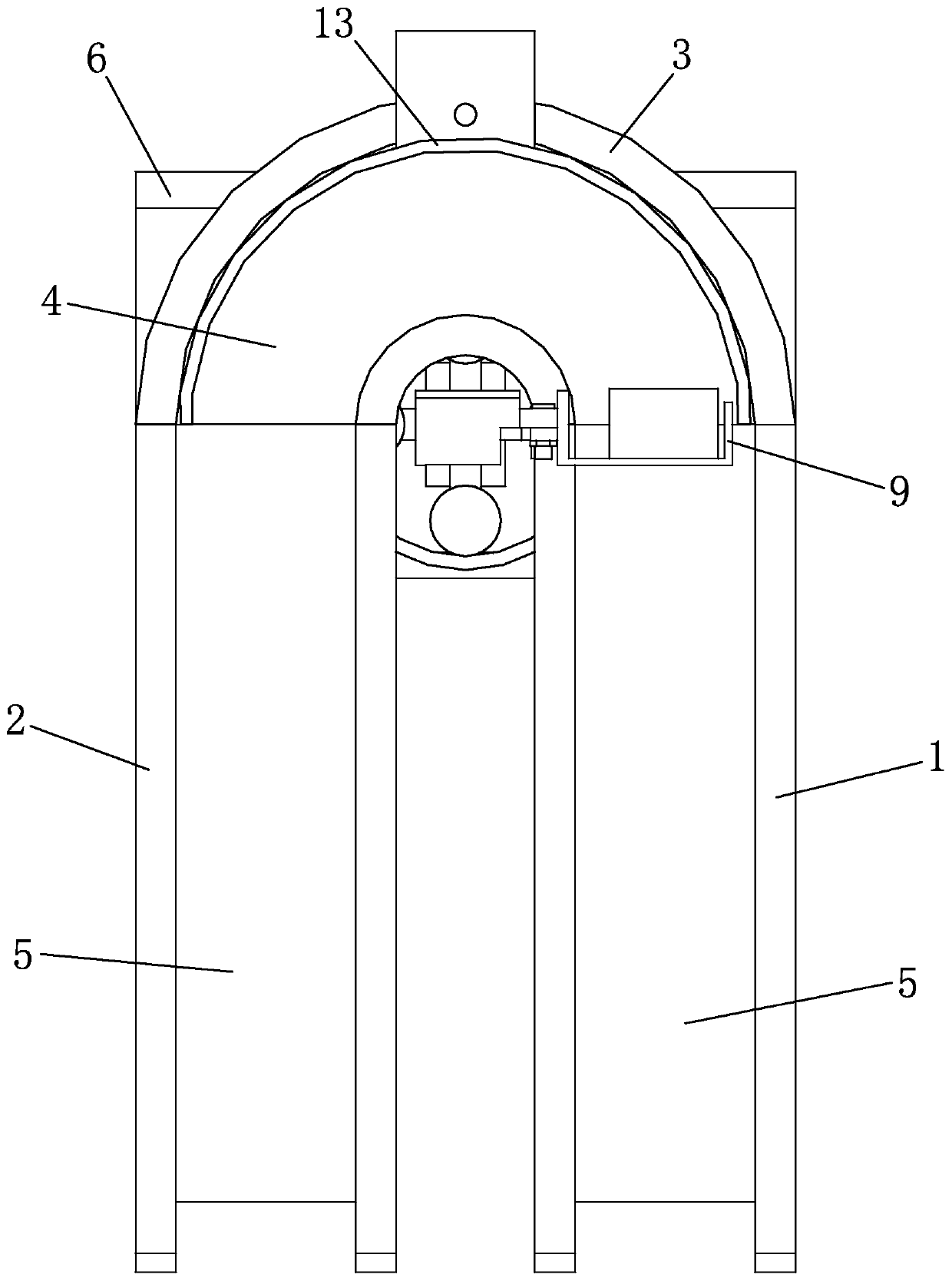

[0032] like Figure 1 to Figure 12 As shown, it is a steering conveying device for steel blocks of hardware accessories according to the present invention, which includes a first conveying platform 1 and a second conveying platform 2, and the first conveying platform 1 and the second conveying platform 2 are arranged in parallel with each other, and the conveying direction on the contrary. Between the first delivery platform 1 and the second delivery platform 2, an arc guide rail 3 is fixedly connected, and the guide surface 4 of the arc guide rail 3 is the same as the delivery surface 5 of the first delivery platform 1 and the delivery surface 5 of the second delivery platform 2. flush. The bottom of the arc guide rail 3 is provided with a leveling seat 6, the leveling seat 6 is fixedly connected with a motor 7, the motor 7 is driven and connected with a rotating assembly 8, the center of the rotating assembly 8 is on the same vertical line as the center of the arc guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com