Tailstock type tilting rotor vertical takeoff and landing unmanned aerial vehicle

A tilt-rotor, vertical take-off and landing technology, applied to vertical take-off and landing aircraft, rotorcraft, motor vehicles, etc., can solve the problems of adding redundant power, instability, and prone to vibration of attitude, so as to simplify the structure and improve reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

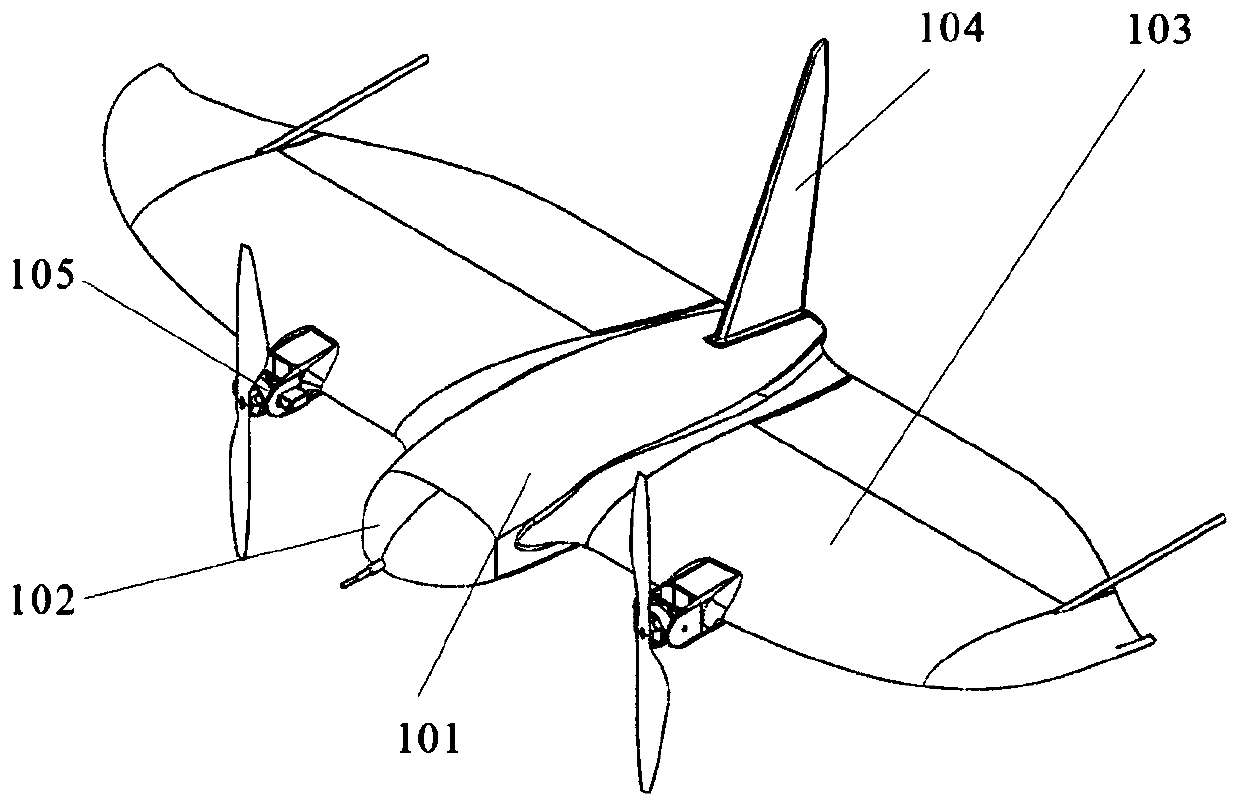

[0029] Such as figure 1 As shown, the tailseat tiltrotor vertical take-off and landing UAV of the present invention includes a fuselage assembly 101 , a nose cover assembly 102 , a wing assembly 103 , an empennage 104 , and a tiltrotor power mechanism 105 . The wing assembly 103 is symmetrically distributed left and right relative to the fuselage, and the tilt rotor power mechanism 105 is installed on the leading edge of the wing assembly 103 . The empennage 104 is perpendicular to the fuselage assembly 101 .

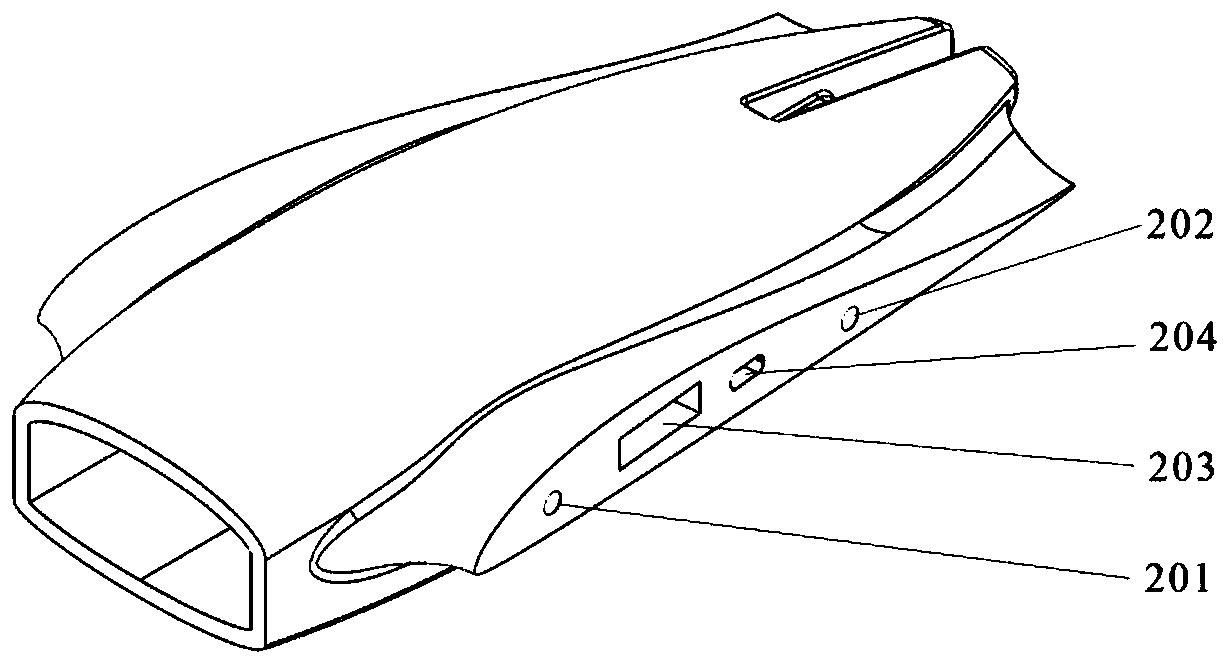

[0030] Such as figure 2 As shown in the fuselage assembly 101 , a first positioning hole 201 , a second positioning hole 202 , a square reinforcing tube hole 203 and an electrical interface A204 are provided at the end surface connected to the wing assembly 103 .

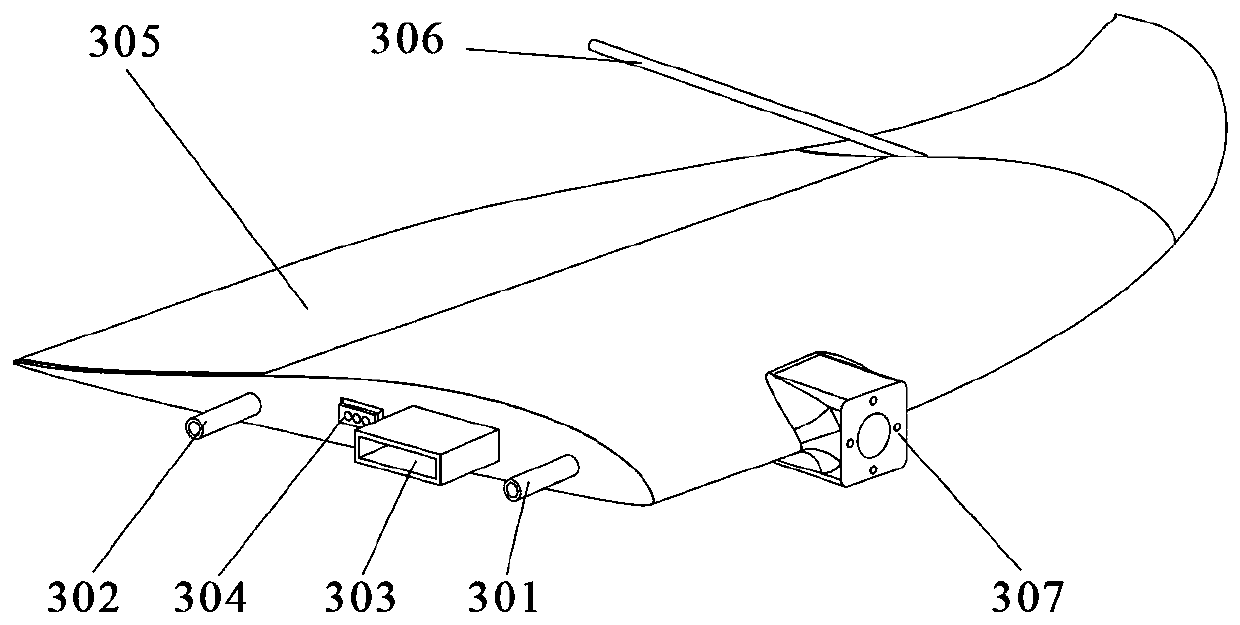

[0031] Such as image 3 The front side of the wing assembly 103 is shown, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com