Nov =el protective board insulation packaging process and lithium battery

A packaging process, lithium battery technology, applied in secondary batteries, battery pack parts, non-aqueous electrolyte batteries, etc., can solve the problem of inability to use circuit board space more effectively, increase the time required for assembly, reduce production efficiency, etc. problems, to achieve the effect of improving space utilization, preventing corrosion, and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

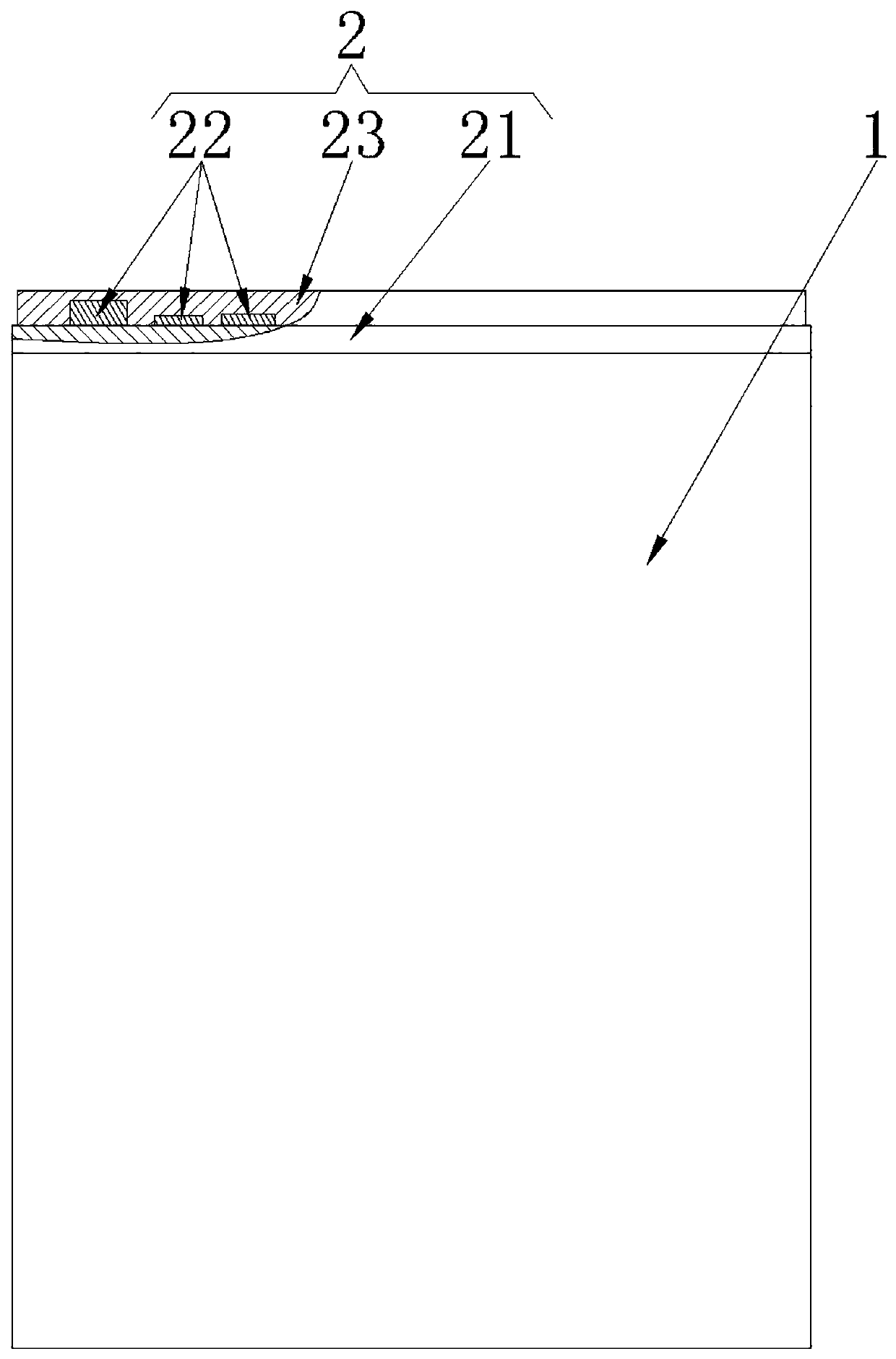

[0021] Such as figure 1 As shown, in this embodiment, the lithium battery includes a battery cell 1 and a protective plate 2 electrically connected to the battery cell 1, and the protective plate 2 includes a circuit board 21 connected to the circuit board 21 The several electronic components 22 and the encapsulation shell 23, the encapsulation shell 23 is integrally injection molded on the several electronic components 22 and the circuit board 21. The circuit board 21 is provided with positive and negative connectors and output pads protruding from the package shell 23 .

[0022] In this embodiment, the outer side of the battery core 1 and the protective plate 2 is covered with a resin layer, and the resin layer is provided with a connection hole matching the output pad, and one of the resin layers A heat dissipation port is provided on the side, and the heat dissipation port is filled with a heat conduction layer. Both the thickness of the resin layer and the heat conducti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com