Camera internal parameter solving method and system based on absolute quadric surface

A quadratic surface and camera technology, applied in image data processing, complex mathematical operations, instruments, etc., can solve problems such as unstable equations, few constraints, and incorrect selection of optimization schemes, so as to reduce the preparation time in the early stage, Requires flexibility and convenience, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

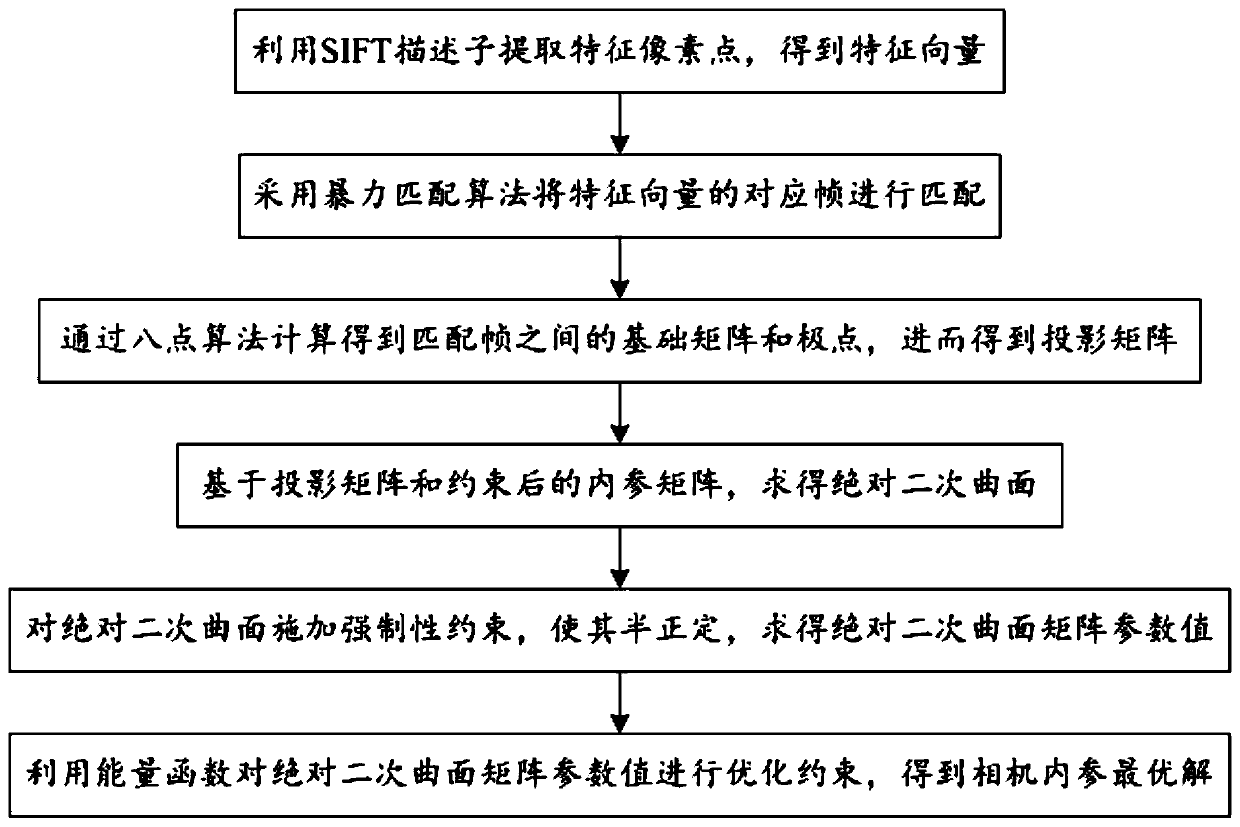

[0076] Such as figure 1 As shown, this embodiment provides a method for solving camera internal parameters based on an absolute quadric surface, including the following steps:

[0077] S1: Since the feature points have good scale, rotation and illumination invariance, etc., the SIFT descriptor extraction is used to extract such as figure 2 The feature pixels of the two-dimensional image of the video sequence shown, the feature pixels are converted into corresponding feature vectors and feature index values;

[0078] S2: if image 3 As shown, based on the feature index value, the brute force matching algorithm is used to match the corresponding frame of the feature vector to obtain an initial matching data, and then the Ransac algorithm is used to eliminate the wrongly matched data, and several matching frames that are correctly matched are obtained. The feature index value here is used as Computational data input for matching distances;

[0079] S3: After the matching rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com