Shearing test device and test method of railway rockfill embankment

A test method and technology of a test device, which are applied in the direction of using a stable shear force to test the strength of materials, etc., can solve the problems of inaccurate methods for confirming the slip surface, lack of railway rock filling and embankment, and low measurement accuracy. The results are reliable, the safety factor is increased, and the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

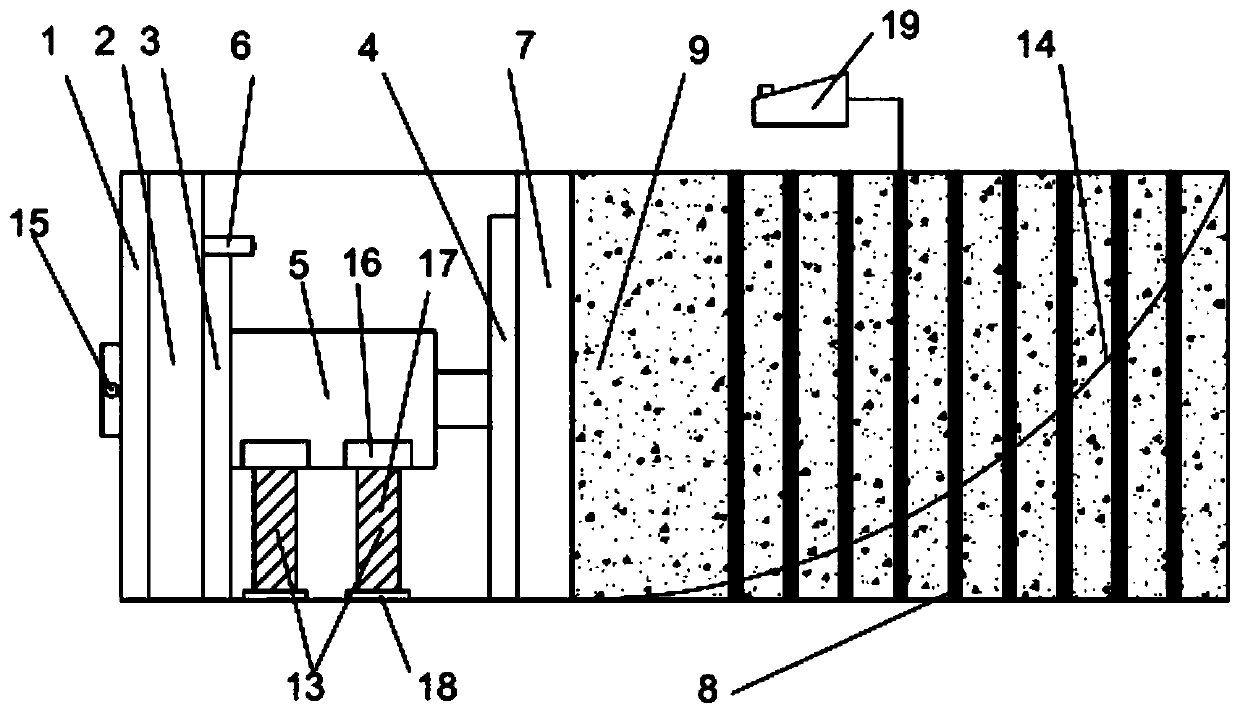

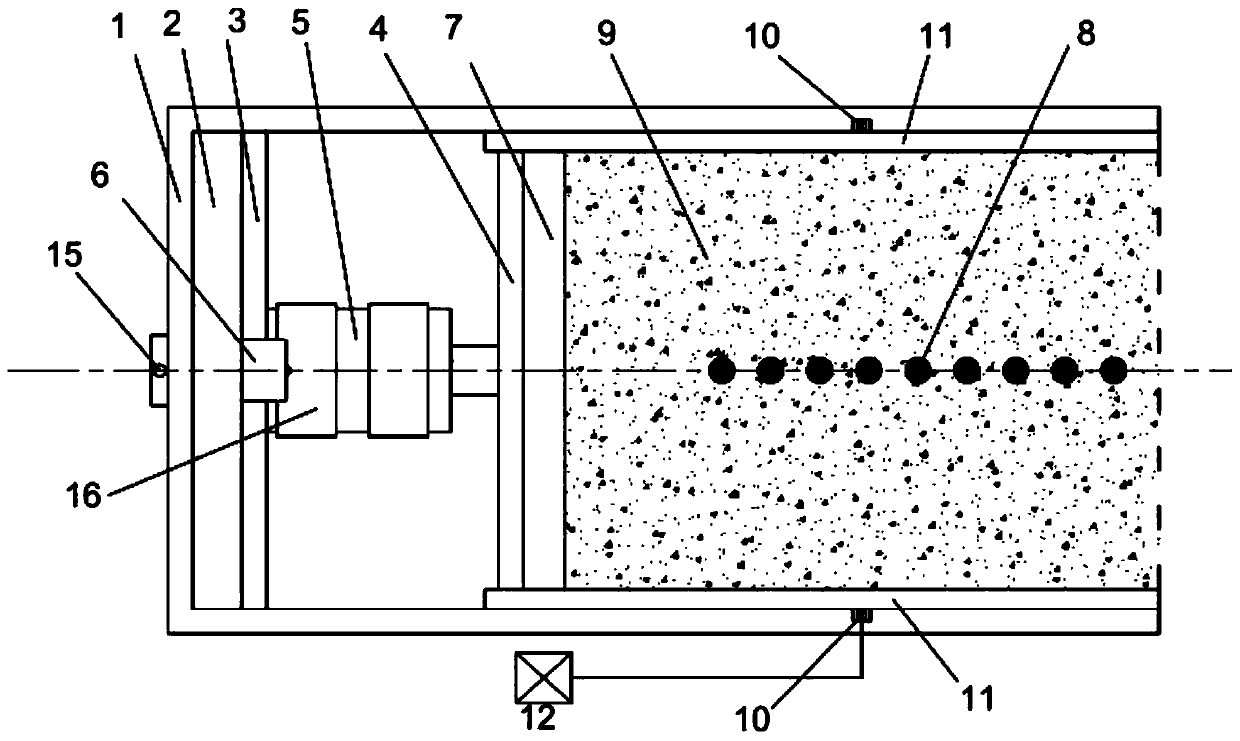

[0073] A new type of railway rockfill embankment shear test device, including fixed steel box 1, hydraulic jack 5, ABS adjustable support 13, PTFE plate 11, inclination sensor 15, laser displacement sensor 6, electromagnetic pressure sensor 10, OTDR test Instrument 19, signal reading device 12.

[0074] Such as figure 1 , figure 2As shown, the fixed steel box 1 is a U-shaped steel frame, and the U-shaped steel frame includes one side plate and two ribs. The U-shaped steel frame is sequentially arranged from the inside to the outside: rear sleepers 2, rear steel plates 3, hydraulic jacks 5, Front steel plate 4 and front sleeper 7, ABS adjustable leveling support 13 is set below the hydraulic jack. The ABS adjustable leveling support 13 is made up of three parts of ABS fixed base 18, ABS thread lifting tube 17, nylon cable tie 16, and ABS thread lifting tube 17 is used for adjusting height. PTFE plates 11 are respectively arranged on the inner sides of the two long sides of ...

Embodiment 2

[0078] A kind of novel railway rockfill embankment shear test method of the present embodiment, uses the device of embodiment one, comprises the following steps:

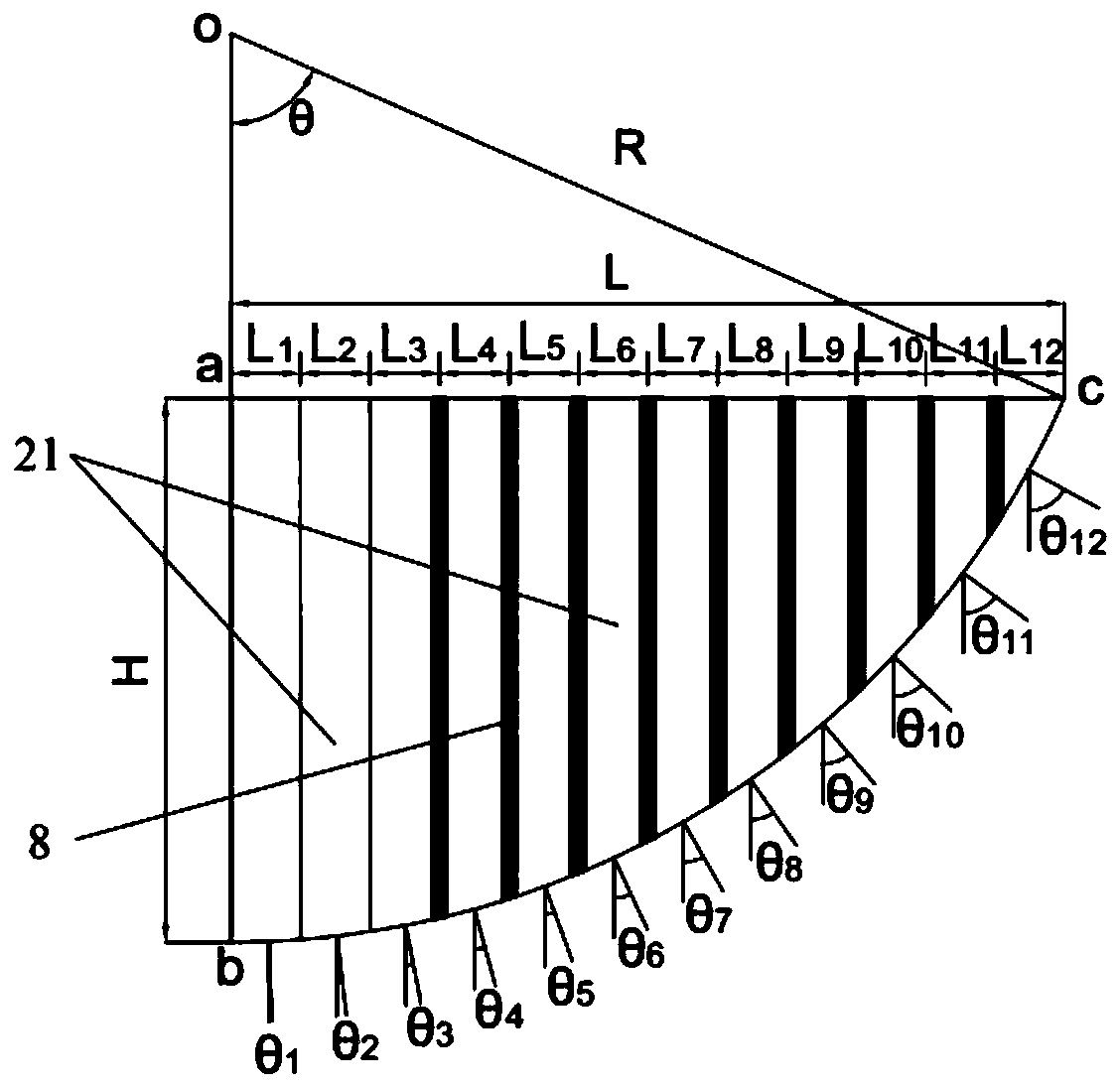

[0079] The first step is to excavate a three-sided vertical cuboid soil to be tested at the predetermined depth of the railway embankment. The specific size of the cuboid is determined by the particle size of the test soil, and the height H is about 5 times the maximum test. Soil particle size, width B is about 1.8H, length L is the same as width W;

[0080] In the second step, a PTFE board is placed on the two sides of the excavated soil to be tested, and the soil material is backfilled and compacted. The contact surface between the PTFE board and the soil material is coated with a layer of lubricating oil;

[0081] The third step is to install and fix the U-shaped steel box, which is perpendicular to the embankment and the U-shaped opening is arranged towards the embankment; the U-shaped steel box includes a side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com