Heavy-duty double-wheel noise testing vehicle for tire-road noise testing

A noise testing and noise testing technology, applied to motor vehicles, measuring devices, measuring vibrations, etc., can solve problems such as complicated counterweight adjustment operations, difficulty in adapting to complex road conditions, and tire-road noise testing equipment being easily affected by the environment. The effect of saving manpower and material resources, simplifying the shape of the trailer, and quickly changing the tire load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

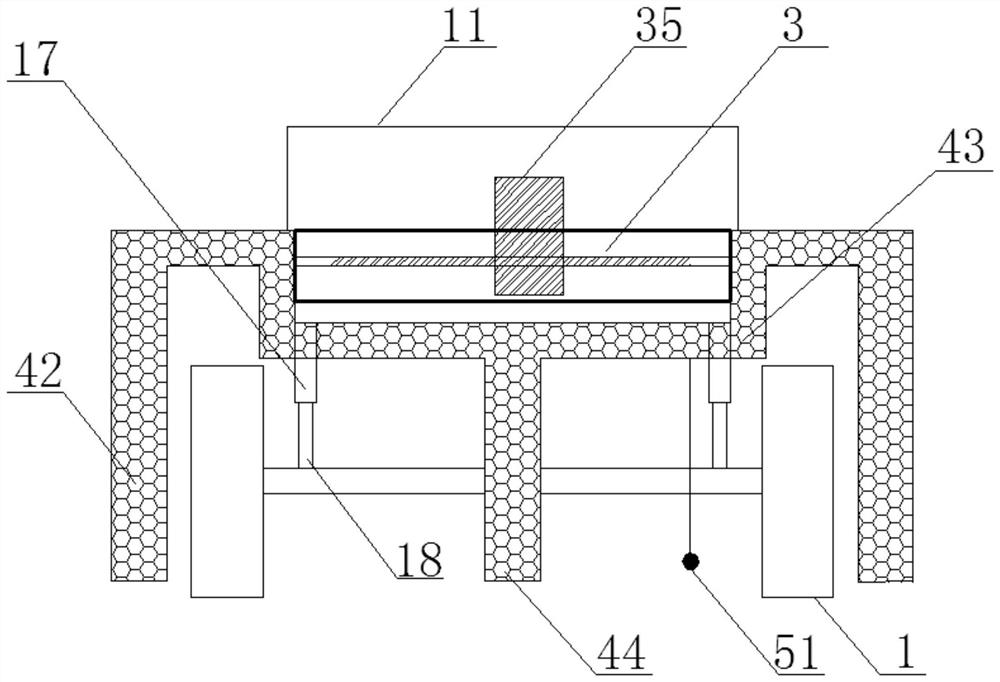

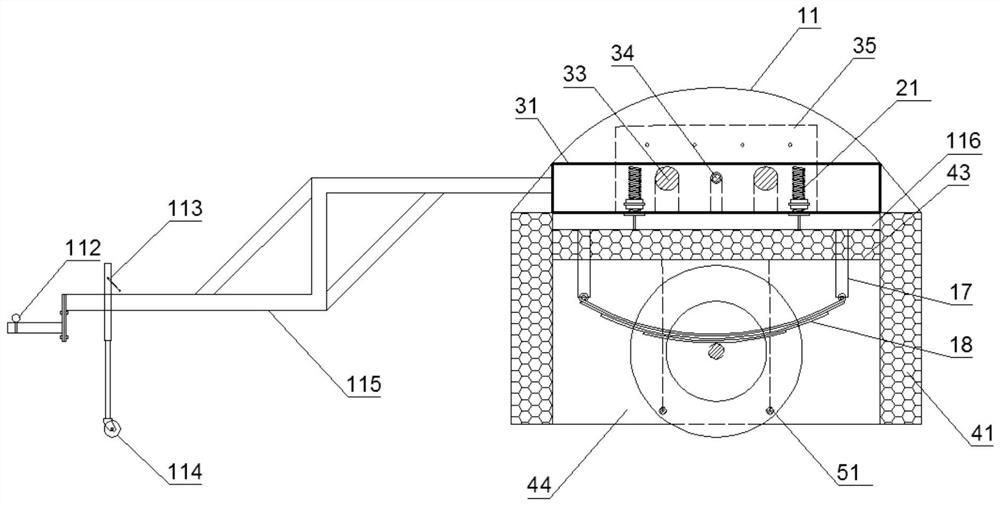

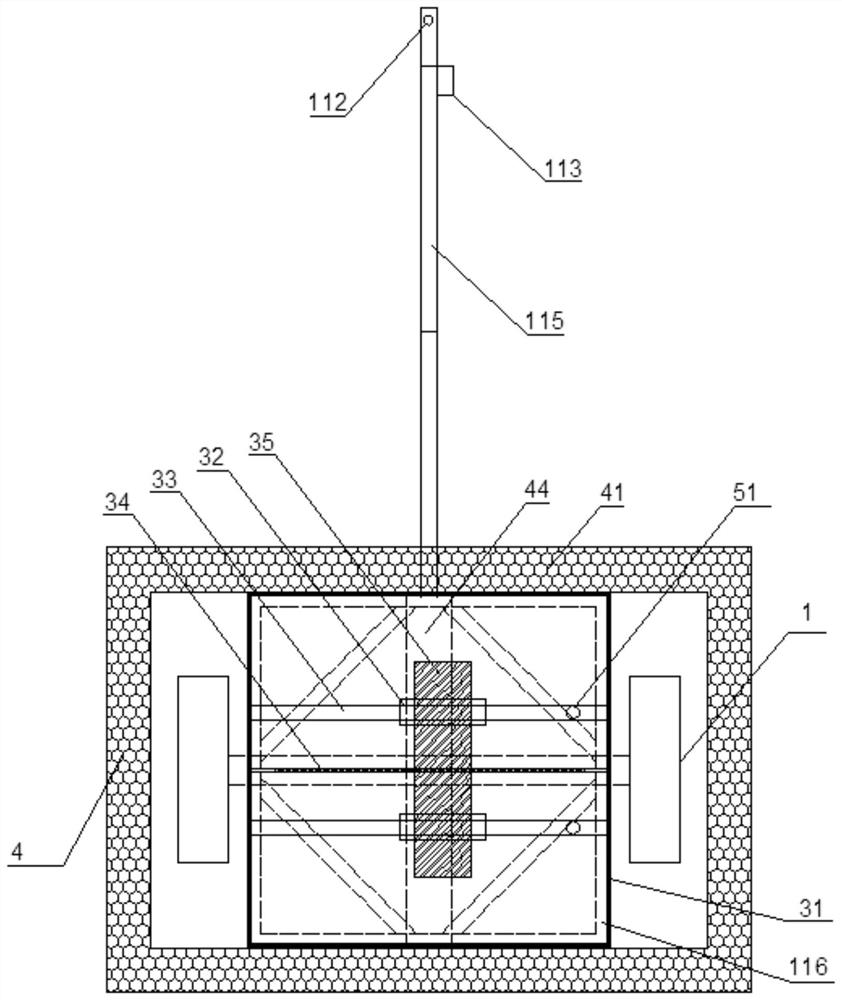

[0027] Specific Embodiment 1: The weight-shifting double-wheel noise detection vehicle used for tire-road noise testing in this embodiment includes a wheel set 1, a leaf spring 18, a square steel frame 116, a lifting device 2, a loading device 3, and a soundproof cover 4 and the data acquisition system, an axle is arranged between the two wheels to form a wheel set 1, and a leaf spring 18 is respectively arranged on the left and right sides of the axle, and the square steel frame 116 is horizontally arranged on the two leaf springs 18 through the support rod 17 Above; wherein the loading device 3 is composed of a square frame 31, a linear bearing 32, a linear transmission shaft 33, a ball screw 34 and a counterweight 35, and two linear transmission shafts 33 are placed horizontally inside the square frame 31 and a ball screw 34, the ball screw 34 is located between two linear transmission shafts 33 and arranged parallel to the linear transmission shafts 33, each linear transmis...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment differs from Embodiment 1 in that an arc-shaped top cover 11 is provided outside the loading device 3 .

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the weight-shifting double-wheel noise detection vehicle used for tire-road noise testing also includes a guide device, and the guide device includes a traction bar 115, a support wheel 114 and Hydraulic telescopic link 113, one end of drawbar 115 is connected with square frame 31, and the other end of drawbar 115 is connected with traction vehicle, and hydraulic telescopic link 113 is vertically arranged on drawbar 115, and the bottom of hydraulic telescopic link 113 is provided with Support wheel 114.

[0034]The support wheels in this embodiment are used to support the car body, indoor short-distance transfer equipment and assist in the installation of the trailer frame on the tractor. adjust. In order to further adapt to different tractor heights, the drawbar is adjusted and fixed with a set screw. A trailer ball head 112 is installed on the top of the draw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com