PCB laser drilling precision testing device and method

A technology of laser drilling and precision testing, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., and can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

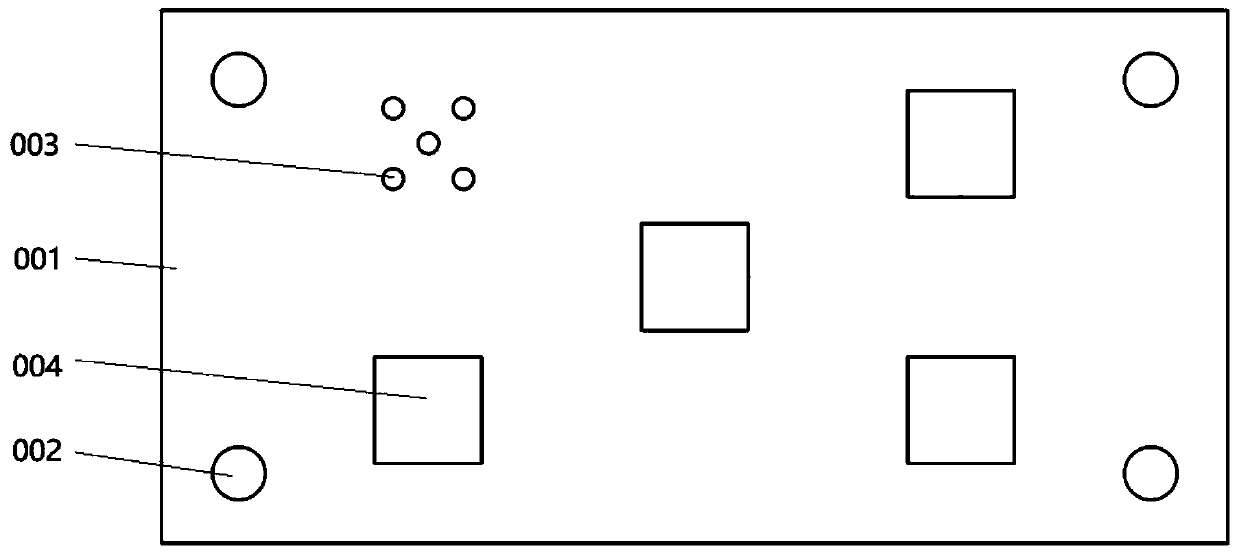

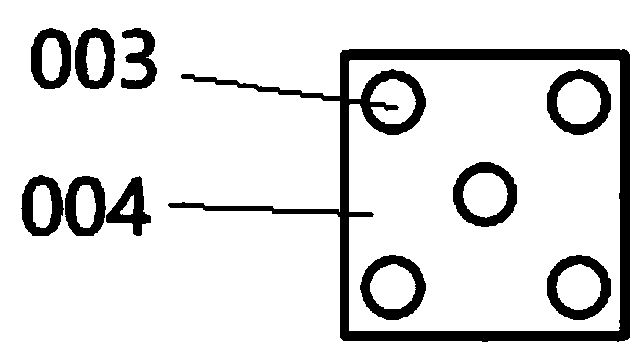

[0025] Such as Figure 1-2 As shown in , a PCB laser drilling precision test device provided by an embodiment of the present invention is characterized in that: it includes a test board 001, and a plurality of positioning holes 002 and a plurality of test holes 003 are opened on the test board 001. Several sheets of rectangular kraft paper 004 are attached to the surface of the test board 001, and each sheet of kraft paper 004 covers the openings of five test holes 003, and the five test holes 003 are respectively located at the center and four corners of the rectangular kraft paper 004.

[0026] Further, the kraft paper 004 is attached to the surface of the test board 001 by crumpled tape.

[0027] Further, the test hole 003 is a through hole with a diameter of 0.4 mm.

[0028] A testing method is also provided: a PCB laser drilling accuracy testing method, comprising the following steps:

[0029] S1, board making, select the PCB board as the test board 001, and drill a num...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com