Filling deflagration energy accumulation volume fracturing method in cracks

A volumetric fracturing and filling technology, which is applied in chemical instruments and methods, mining fluids, earth drilling, etc., can solve the problems of unclear detonation position, wellbore damage, and inability to completely detonate explosives, etc., and achieves convenient and cost-effective operation , saving dosage and increasing the complexity of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

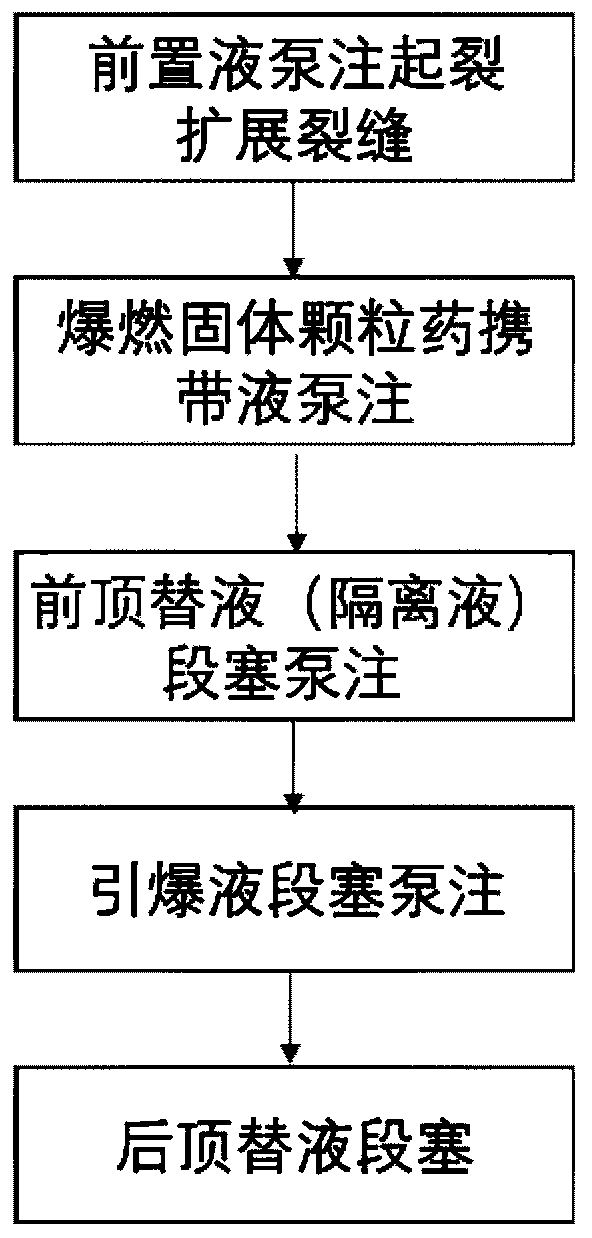

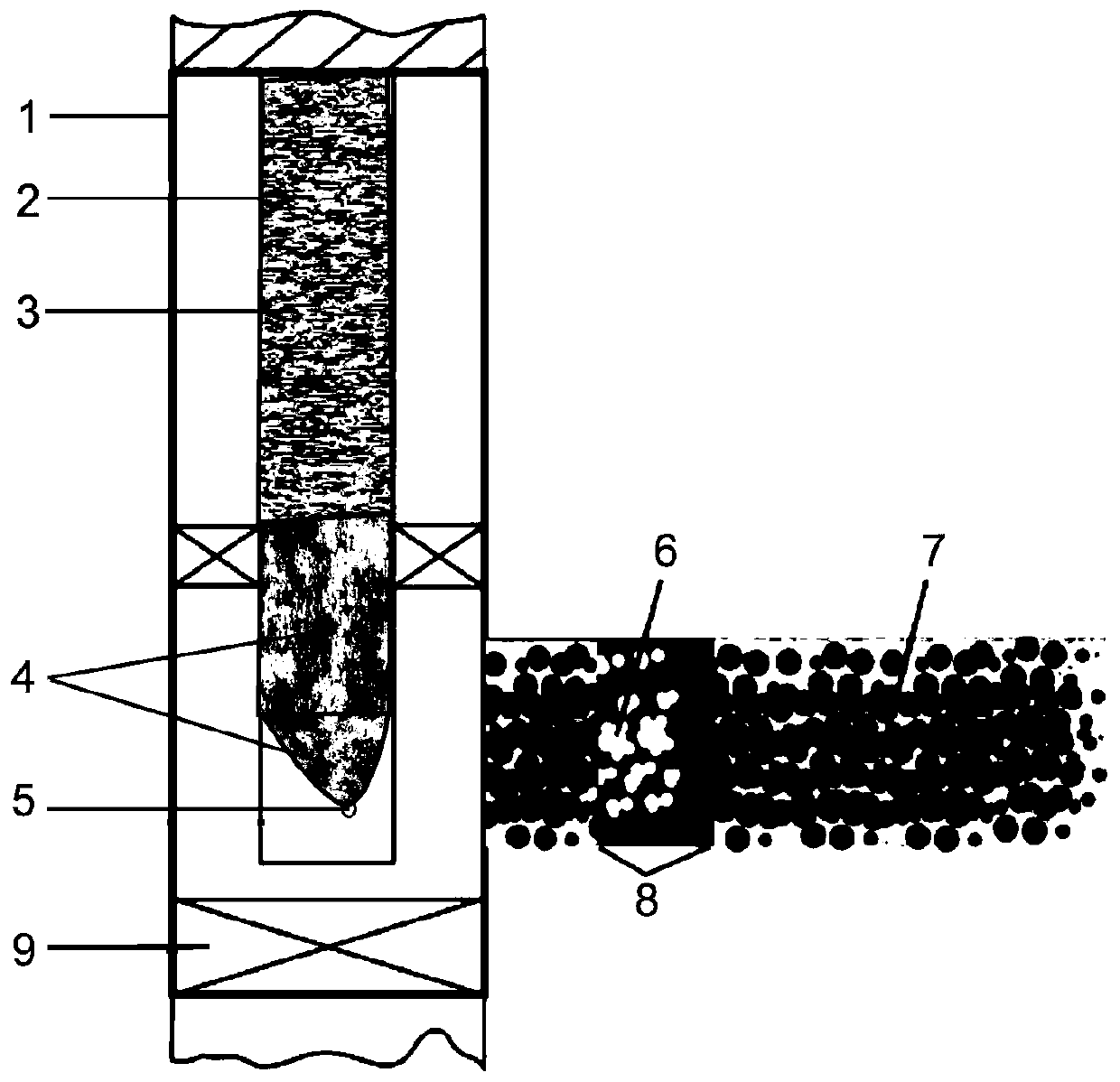

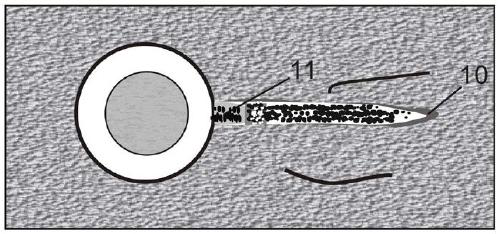

[0036] Such as figure 1 , figure 2 The shown is an oil and gas layer fracturing stimulation of an in-fracture filling type deflagration energy-gathering volume fracturing process, which uses an in-fracture filling method to press a deflagration system into the fractured reservoir where the target well is located. The steps are as follows:

[0037] An in-fracture filling type deflagration energy-gathering volume fracturing method, the method includes the following steps:

[0038] (1) The pre-fluid is pumped to initiate and expand cracks; the composition of the pre-fluid is guar gum fracturing fluid with a viscosity of 60-100mPa.s. The dosage is calculated and determined according to the crack design scale and crack propagation simulation.

[0039] (2) The deflagration solid granular drug is pumped with sand-carrying fluid, and the solid granular drug is carried to fill the cracks; the sand-carrying fluid is self-breaking cross-linked guar gum fracturing fluid. The solid gr...

Embodiment 2

[0060] A crevice-filled deflagration energy-gathering volumetric fracturing method, the steps of which are as described in Example 1, except that the mass ratio of granular propellant powder to aluminum powder in step (2) is 1:1.

Embodiment 3

[0062] An in-fracture filling deflagration energy-gathering volumetric fracturing method, the steps of which are as described in Example 1, except that the injection amount of the pre-displacement fluid in step (3) is 35% of the wellbore volume of the target well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com