Installation structure for assembly type buckle top corner line

A technology for installing structures and corner lines, applied in building construction, construction, etc., can solve problems such as warping, easy to dry and crack, complicated operation, etc., and achieve the effects of prolonging service life, convenient transportation, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

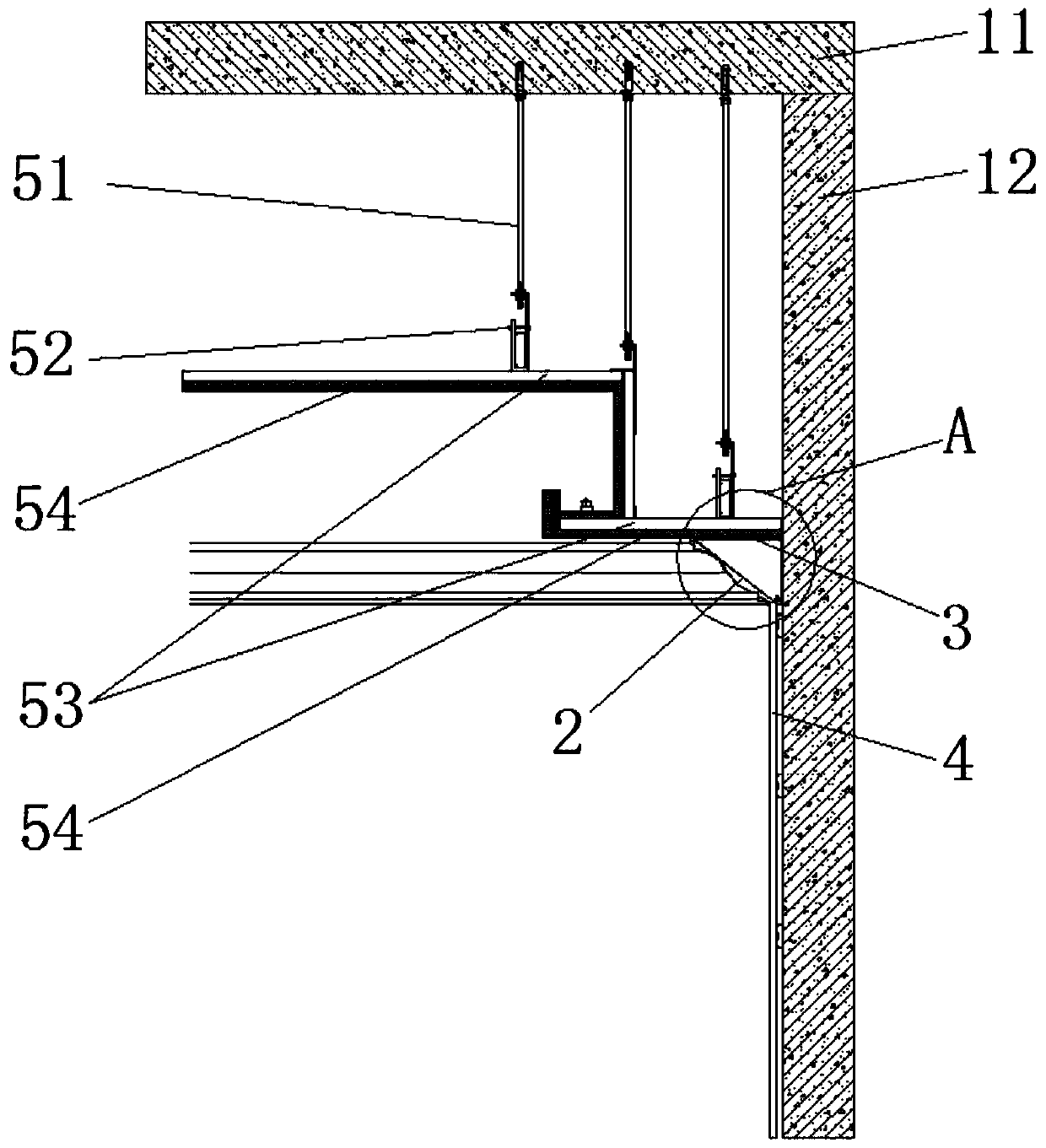

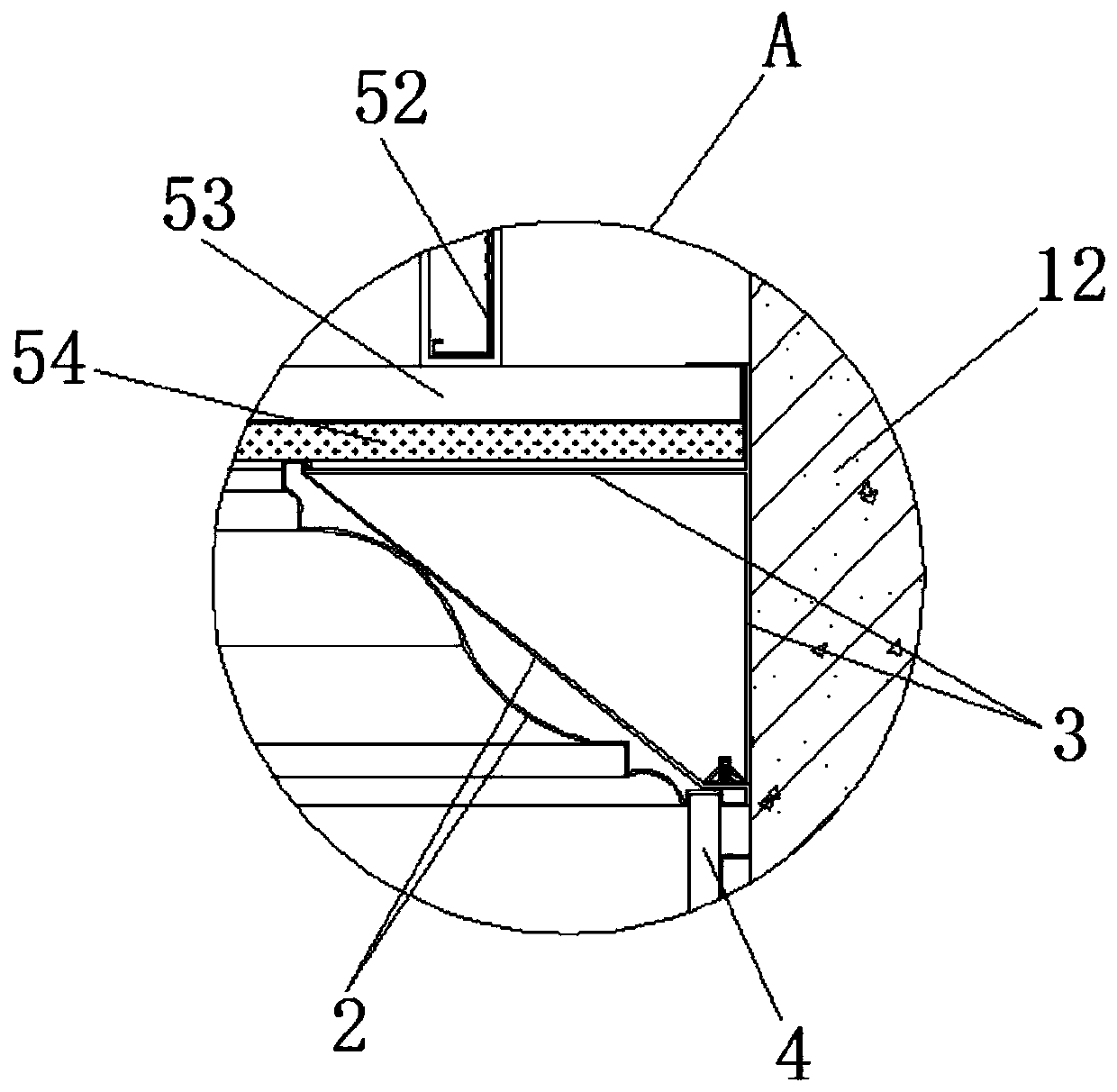

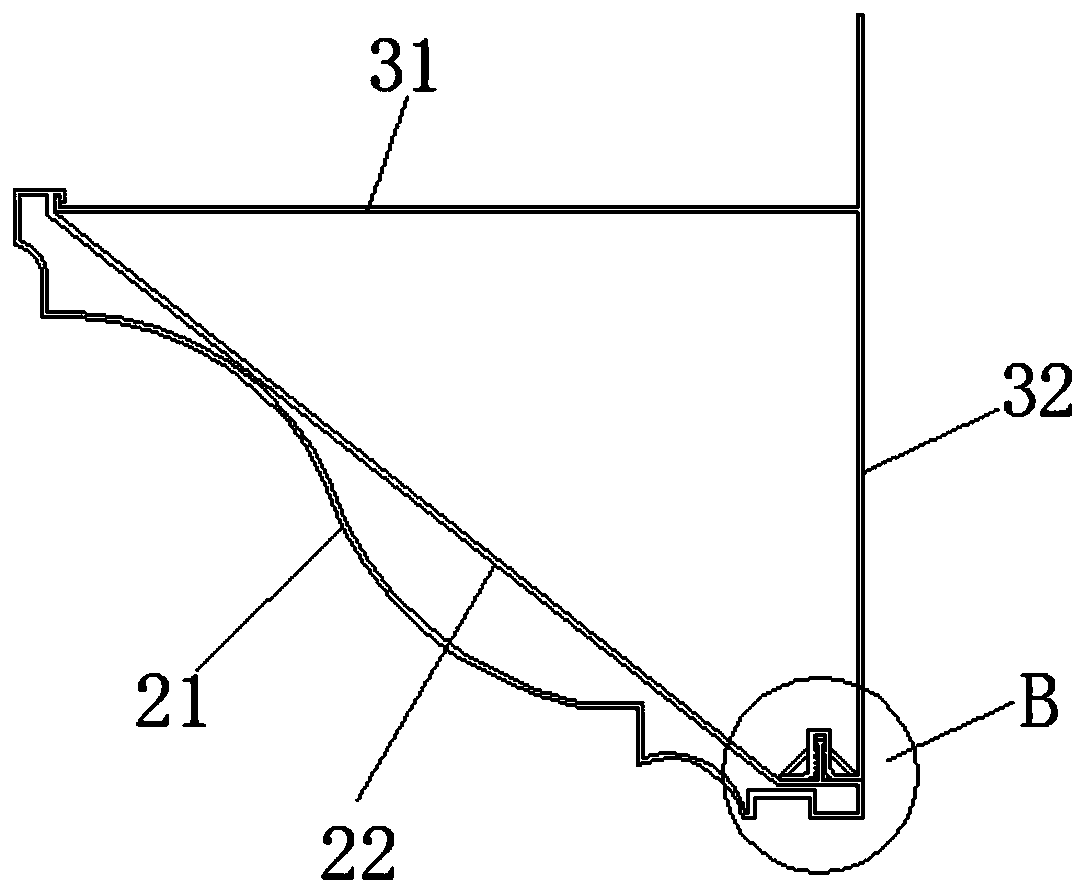

[0036] see Figure 1 to Figure 5 , the figure shows a prefabricated buckle corner line installation structure provided by Embodiment 1 of the present invention, which includes: the original wall, which includes the top wall 11 and the side wall 12; the suspended ceiling, which is arranged on the top wall 11 Below, the surrounding is connected with the side wall 12; the corner line 2, which includes a support strip 21 and a decorative strip 22, the two ends of the support strip 21 are connected with the two ends of the decorative strip 22, and the support strip 21 is located at the edge of the decorative strip 22 Inside, the top and bottom of the support bar 21 are respectively provided with a hook 211 and a clip 212; the connecting clip 3 includes a first connecting part 31 and a second connecting part 32 perpendicular to the first connecting part 31, the first The outer end of the connector 31 is provided with an upwardly protruding buckle 311 , and the bottom of the second c...

Embodiment 2

[0045] see Figure 2 to Figure 3 , the figure shows a prefabricated buckle top corner line installation structure provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first The top of the second connecting piece 32 protrudes from the first connecting piece 31, and the protruding length is consistent with the height of the suspended ceiling. Through the setting of the above structure, after the ceiling is installed, the protruding part of the second connector 32 can be preset between the side wall 12 and the ceiling, that is, it can be clamped and positioned by the contact force on both sides, so as to facilitate the connection of the clips 3 fixed work in the later stage.

Embodiment 3

[0047] see Figure 3 to Figure 6, the figure shows a prefabricated buckle top corner line installation structure provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: The lower part of the inner wall on both sides of the slot 321 is set in a zigzag shape; the outer sides of the slot 321 are provided with reinforcing ribs 322, and the ribs 322 are respectively connected to the top and bottom of the slot 321; , the protrusion 213 is arranged outward along the width direction of the bar 212; the hook 211 is in an "L" shape. Through the setting of the above structure, the zigzag structure inside the card slot 321 can increase the force of engagement with the card bar 212. In addition, the reinforcing rib 322 can improve the self-strength of the card slot 321, and the card protrusion 213 can further improve the connection between the card bar 212 and the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com