Frame type storage partition wall and installation method thereof

A frame-type and frame-based technology, applied to walls, building structures, cabinets with rigid structural features, etc., can solve the problem of hanging gravity, load-bearing capacity not meeting storage requirements, modeling and large-size space restrictions, and inability to Respond to problems such as the conversion test on both sides of the partition wall, so as to avoid the damage of the profile itself, reduce the thickness of the finished surface, and increase the hanging gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

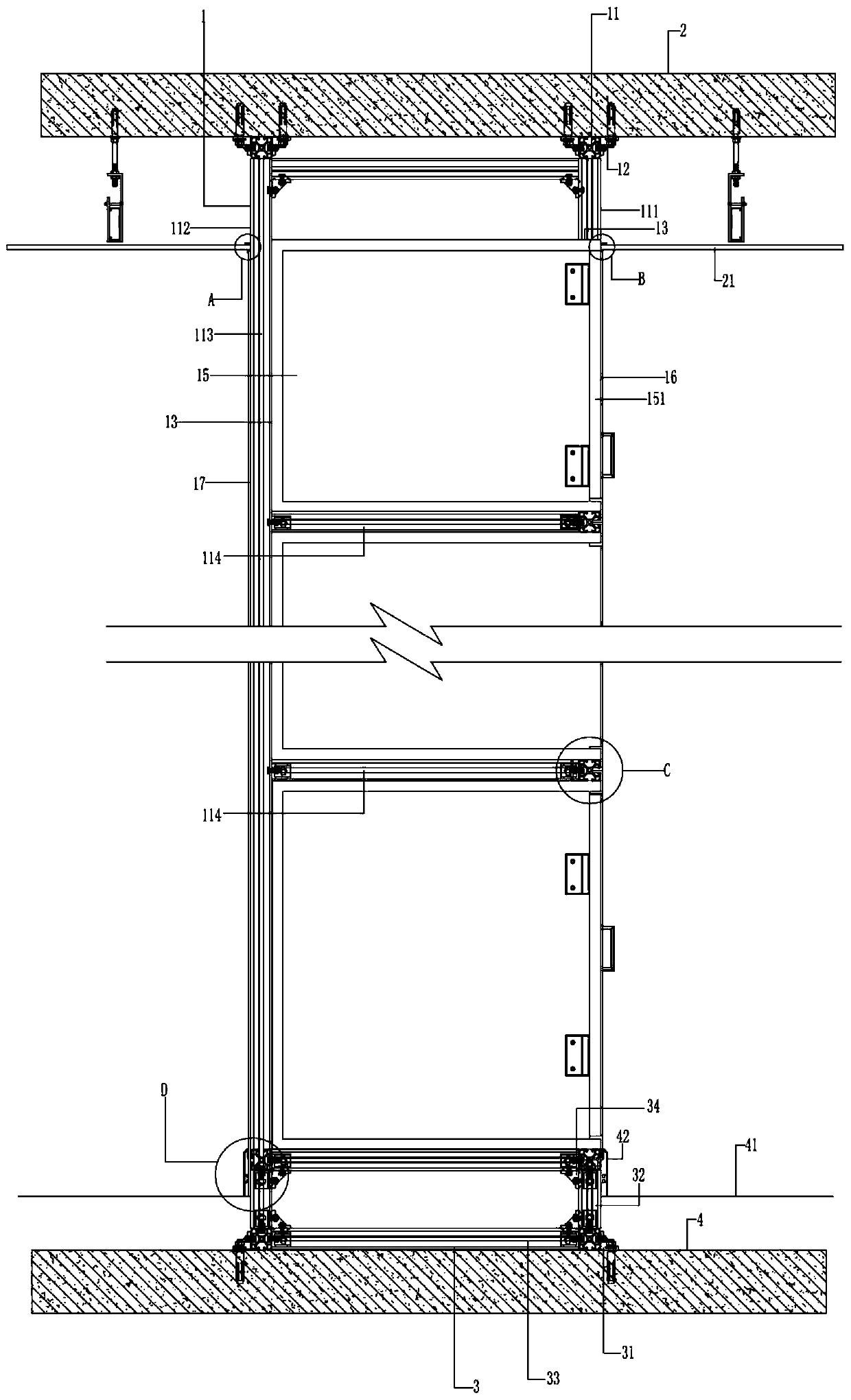

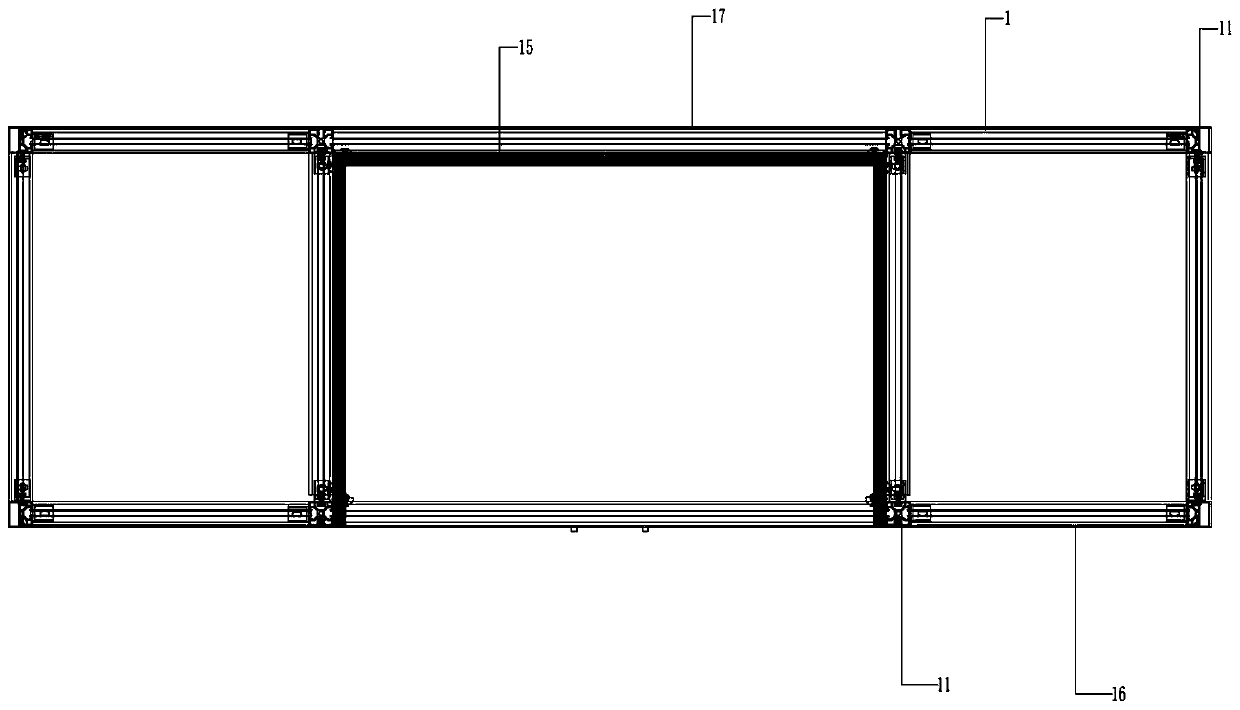

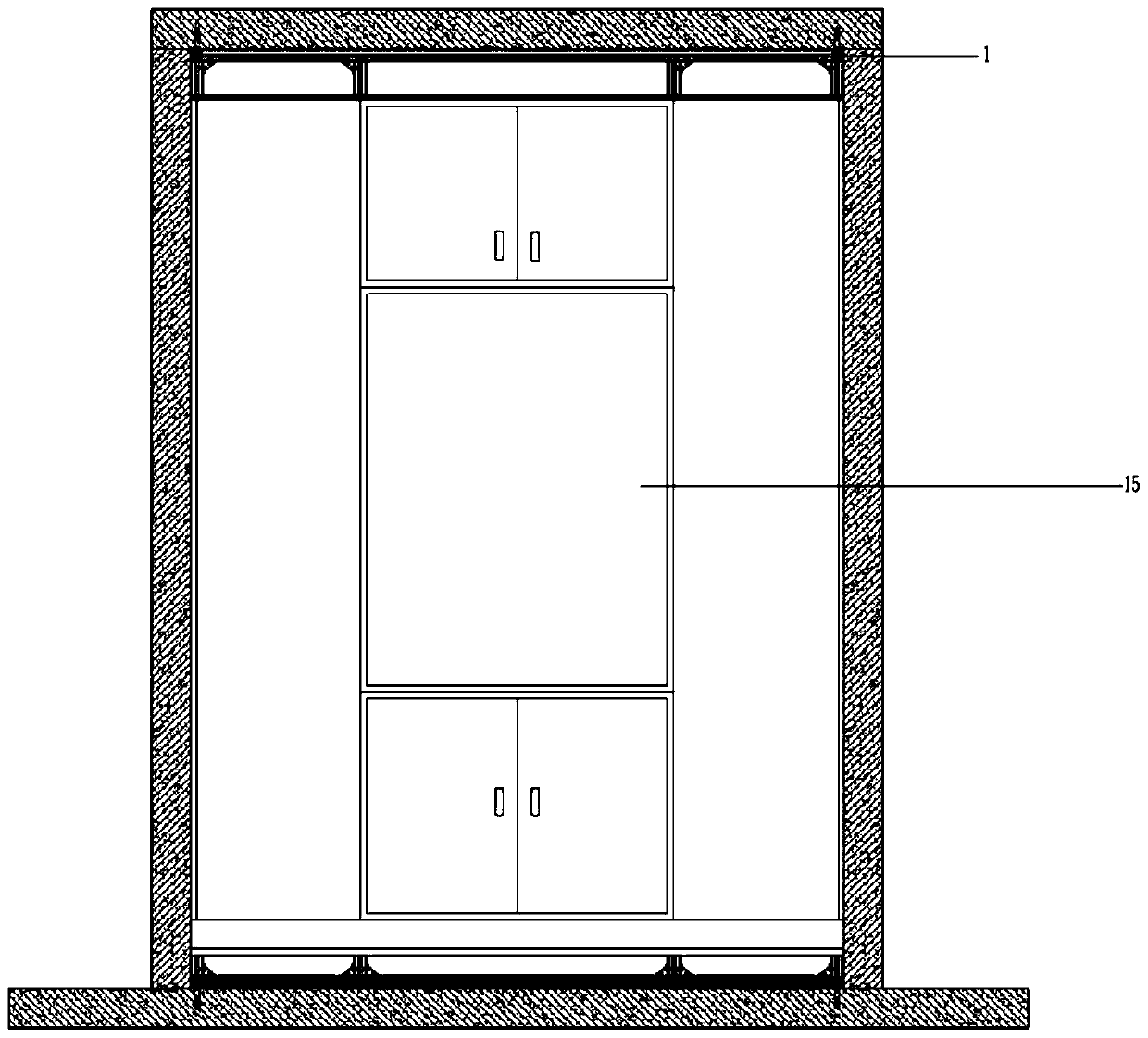

[0039] see Figure 1 to Figure 7, the figure shows a frame-type storage partition wall provided by Embodiment 1 of the present invention, which includes a first steel frame 1, the first steel frame 1 is a rectangular frame, and the top of the first steel frame 1 Two horizontal first square steel bars 11 are respectively fixedly connected to the opposite sides, and two first corner fittings 12 are fixedly connected to the opposite sides of the first square steel 11 respectively, and the cross section of the first corner fittings 12 is a right angle. The sides are triangular, and the first corner piece 12 is fixedly connected to the top base layer 2 at the same time. The bottom of the steel frame 1 is fixedly connected to the second steel frame 3. The second steel frame 3 is a rectangular frame, and the second steel frame 3 forms a steel frame. The overhead layer at the bottom of the frame 1, two second corner fittings 31 are respectively fixedly connected to the opposite sides ...

Embodiment 2

[0042] see Figure 1 to Figure 7 , the figure shows a frame-type storage partition wall provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: third-party steel 114 A rectangular notch 115 is provided at the end on the first side 111, and a fourth square steel 116 is embedded in the rectangular notch 115. The cross-sectional area of the fourth square steel 116 is equal to half of the cross-sectional area of the third-party steel 114 , and the side of the fourth square steel 116 is fixedly connected to a rotatable flange 1162 by bolts 1161, the flange 1162 is located in the inner cavity of the third party steel 114, when the door 151 of the storage box 15 is closed, the second The square steel 116 transmits the impact force to the flange 1162 , and the flange 1162 disperses the force by rotating, and the impact force does not continue to extend towar...

Embodiment 3

[0044] see Figure 1 to Figure 7 , the figure shows a frame-type storage partition wall provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the second steel The frame 3 includes a plurality of parallel and vertically arranged fifth square steels 32, the bottom of the fifth square steels 32 is fixedly connected to a bottom rectangular frame 33, and the bottom rectangular frame 33 is formed by splicing at least four sixth square steels 331, The second corner fitting 31 is fixedly connected on the outer surface of the bottom rectangular frame 33, and the top of the fifth square steel 32 is fixedly connected on the third corner fitting 34, and the cross section of the third corner fitting 34 is a right-angled equilateral triangle, and the third corner fitting 34 At the same time, the bottom of the first steel frame 1 is fixedly connected. Through the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com