Secondary color adjustment-free machine head outer mold sleeve of wire extruder

A technology of outer mold sleeve and extruder, which is used in the manufacture of circuits, electrical components, cables/conductors, etc., to avoid waste, reduce harshness, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

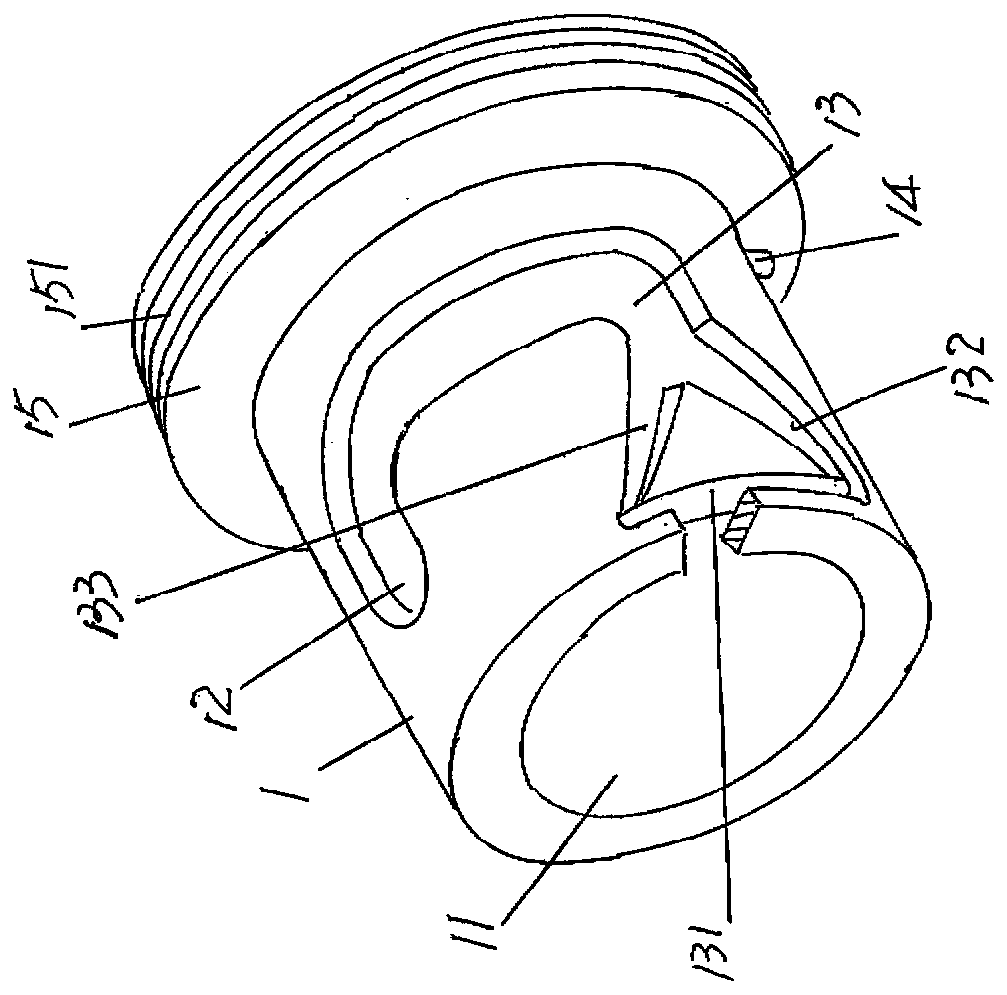

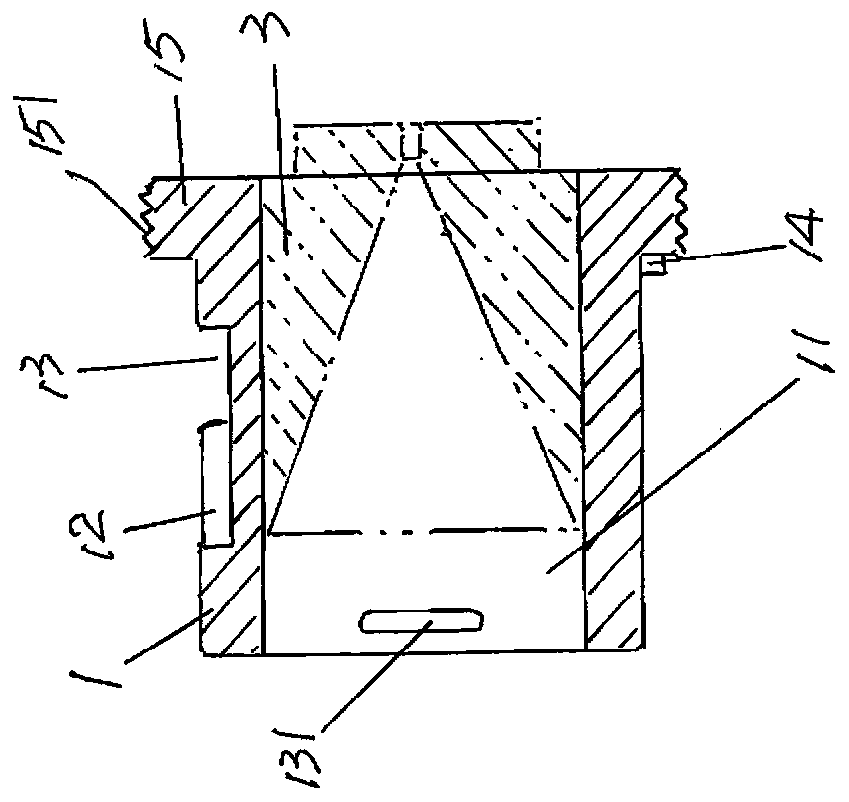

[0027] See figure 1 with figure 2 , shows an outer mold casing body 1, the center of the outer mold casing body 1 forms a core cavity 11 that passes through from one end of the outer mold casing body 1 to the other end, and is formed on the outer wall of the outer mold casing body 1. There are color masterbatch feeding groove 12 and diversion groove 13, color masterbatch feeding groove 12 communicates with diversion groove 13, diversion groove 13 communicates with diversion port 131, diversion port 131 communicates with mold core cavity 11 .

[0028] As the technical gist of the technical solution provided by the present invention: the aforementioned diversion port 131 is opened on the wall body at the left end of the outer mold casing body 1 and is in the form of a circular arc cavity surrounded by surrounding walls. Figuratively speaking, the above-mentioned diversion groove 131 is not only in communication with the mold core cavity 11 but also in communication with the ...

Embodiment 2

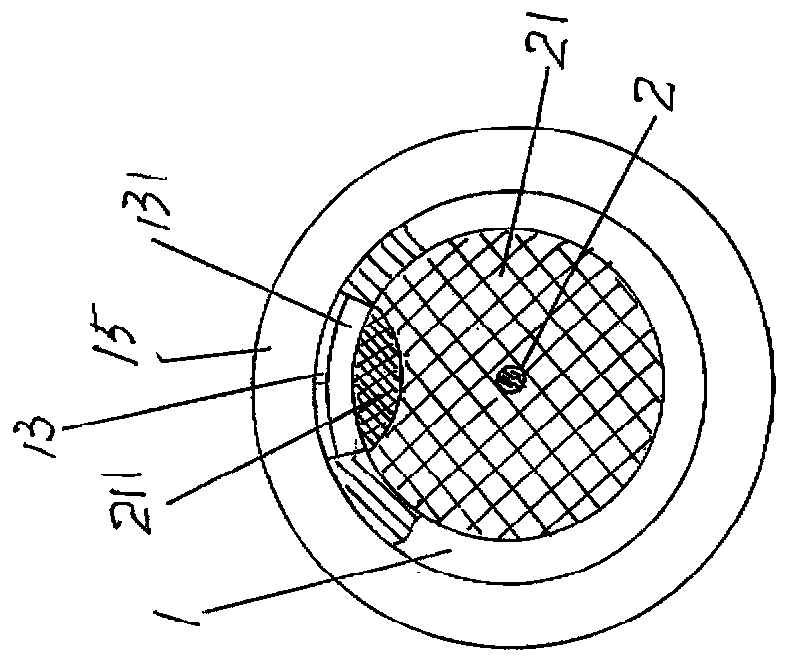

[0038] See Figure 4 , with respect to embodiment 1, present embodiment is owing to have adopted two diversion openings 131 facing each other, thus between color masterbatch feeding tank 12 and diversion tank 13, additional flow diversion groove 121 is added, by color masterbatch feeding The color masterbatch introduced in the groove 12, that is, the intermediate color material, is supplied to the two diversion grooves 13 through the diversion groove 121, and then passes through the first material diversion channel I132 of the two diversion ports and the second material diversion channel II133 of the two diversion ports. All the other are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com