Bag grabbing mechanical arm for sludge bag breaking equipment

A manipulator and bag breaking technology, which is applied to manipulators, program-controlled manipulators, chucks, etc., can solve the problems of incapable sludge bag clamping, rigid structure, and inconvenience for the rapid movement of manipulators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

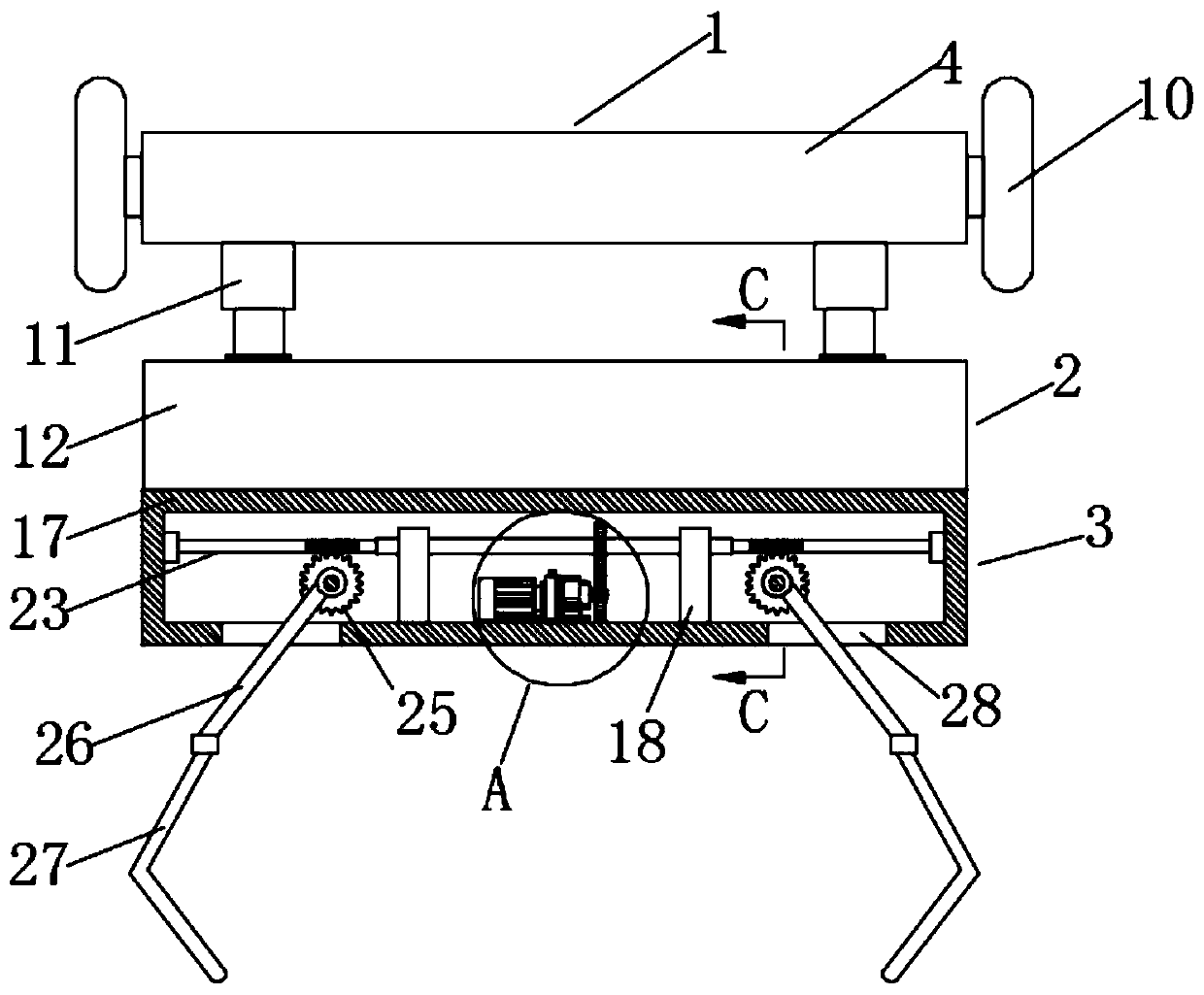

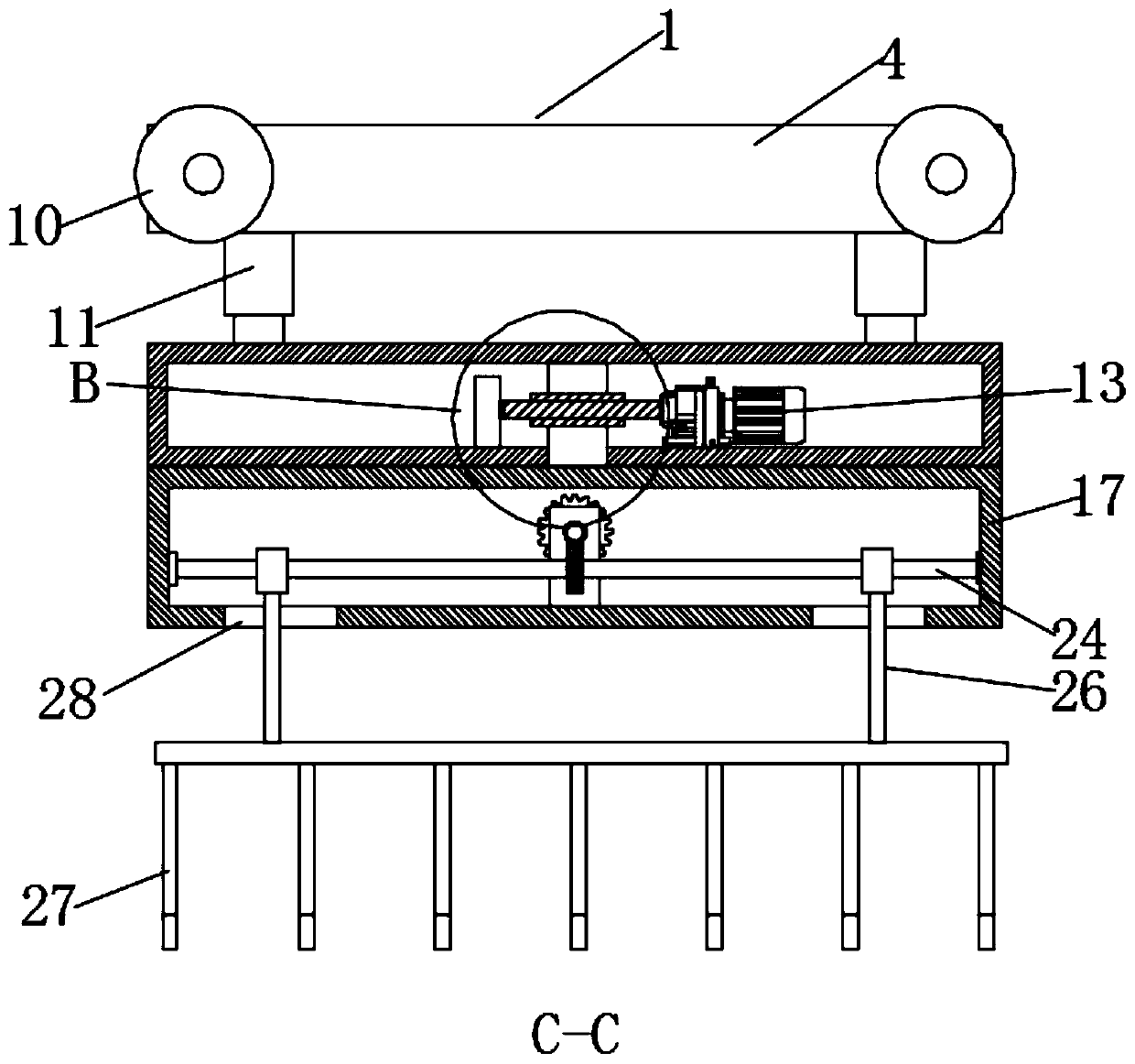

[0021] like Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: a bag grabbing manipulator for sludge bag breaking equipment, including a moving mechanism 1, a steering mechanism 2 and a grabbing mechanism 3, and the bottom of the moving mechanism 1 is provided with a steering mechanism 2 , the bottom of the steering mechanism 2 is provided with a grasping mechanism 3, and the moving mechanism 1 is composed of a moving box 4, a driven shaft 5, a driving shaft 6, a driven bevel gear 7, a driving motor 8, a driving bevel gear 9 and The drive wheel 10 is composed of one end inside the moving box 4 which is rotatably connected with a driven shaft 5, and one end which is far away from the driven shaft 5 inside the moving box 4 is rotatably connected with a driving shaft 6, and the middle part of the driving shaft 6 A driven bevel gear 7 is fixedly connected, and a driving motor 8 is fixedly installed inside the moving box 4, and the output end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com