Salting device used for intestinal casing shrinking machine

A shrinking machine and casing technology, which is applied in the processing of animal intestines, etc., can solve the problems of increased casing processing costs, low casing processing efficiency, and waste of labor, and achieve the effects of uniform salting on casings, avoiding labor waste, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

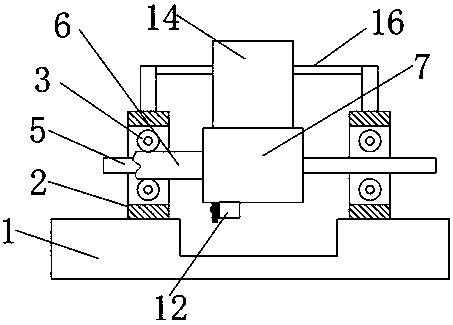

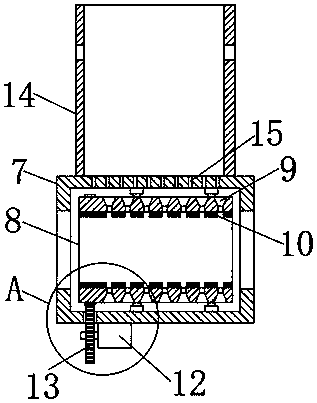

[0020] see Figure 1-4 , this embodiment provides a salt loading device for casing shrinking machine, including a base 1 and a box body 7, both sides of the top of the base 1 are fixedly connected with a conveying frame 2, and there is a transmission between the two conveying frames 2 The casing body 6 is sleeved on the outer wall of the rod 5 and the conveying rod 5, and the middle part of the box body 7 is rotatably connected with a rotating cylinder 8. The side wall of the rotating cylinder 8 is provided with several tapered holes 9, and the inner wall of the rotating cylinder 8 is fixedly connected with a brush 10. The side wall of the rotating cylinder 8 is fixedly connected with a rack 11, the bottom of the box body 7 is fixedly installed with a second motor 12, the output end of the second motor 12 is fixedly connected with a gear plate 13, and the gear plate 13 is matched with the rack 11 for transmission connection. A feed cylinder 14 is fixedly connected to the top o...

Embodiment 2

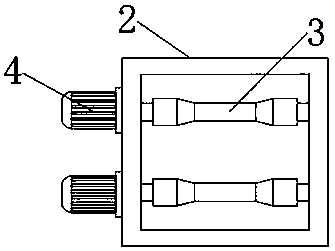

[0023] see Figure 1-4 , made further improvement on the basis of embodiment 1: two rotating rollers 3 are connected in rotation in the conveying frame 2, two first motors 4 are fixedly installed on the side wall of the conveying frame 2, and the output ends of the first motor 4 are connected with the rotating rollers respectively. The roller 3 is fixedly connected, and the first motor 4 can drive the rotating roller 3 to rotate. The side walls of the two rotating rollers 3 are grooved, and the distance between the middle parts of the two rotating rollers 3 is the same as the diameter of the casing body 6. The conveying position of the conveying rod 5 can be limited to prevent the conveying rod 5 from shifting during transportation. The inner wall of the box body 7 is fixedly equipped with a universal ball, and the universal ball is supported on the outer wall of the rotating cylinder 8, and can be passed through the universal ball. To ensure the performance of the rotation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com