Alternating-current sleeve structure

A bushing and conductive tube technology, applied in the direction of screwing one conductor into another conductor, transformer/inductor parts, electrical components, etc., can solve the problem that the displacement can only occur at the top of the cover plate 500 and the contact force of the thread is reduced. , the looseness of the conductive head 200, etc., to avoid the poor contact of the connecting thread and improve the waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

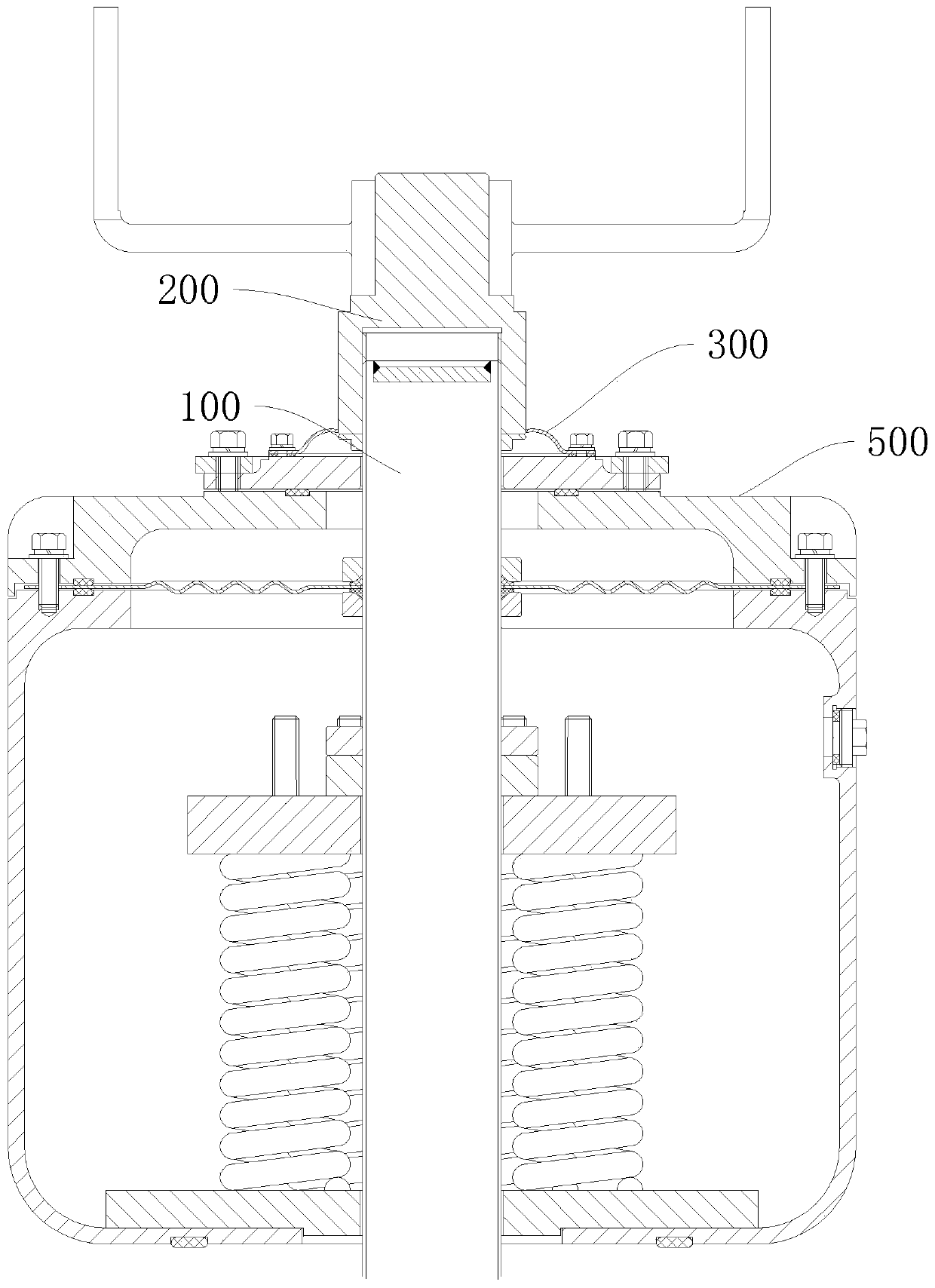

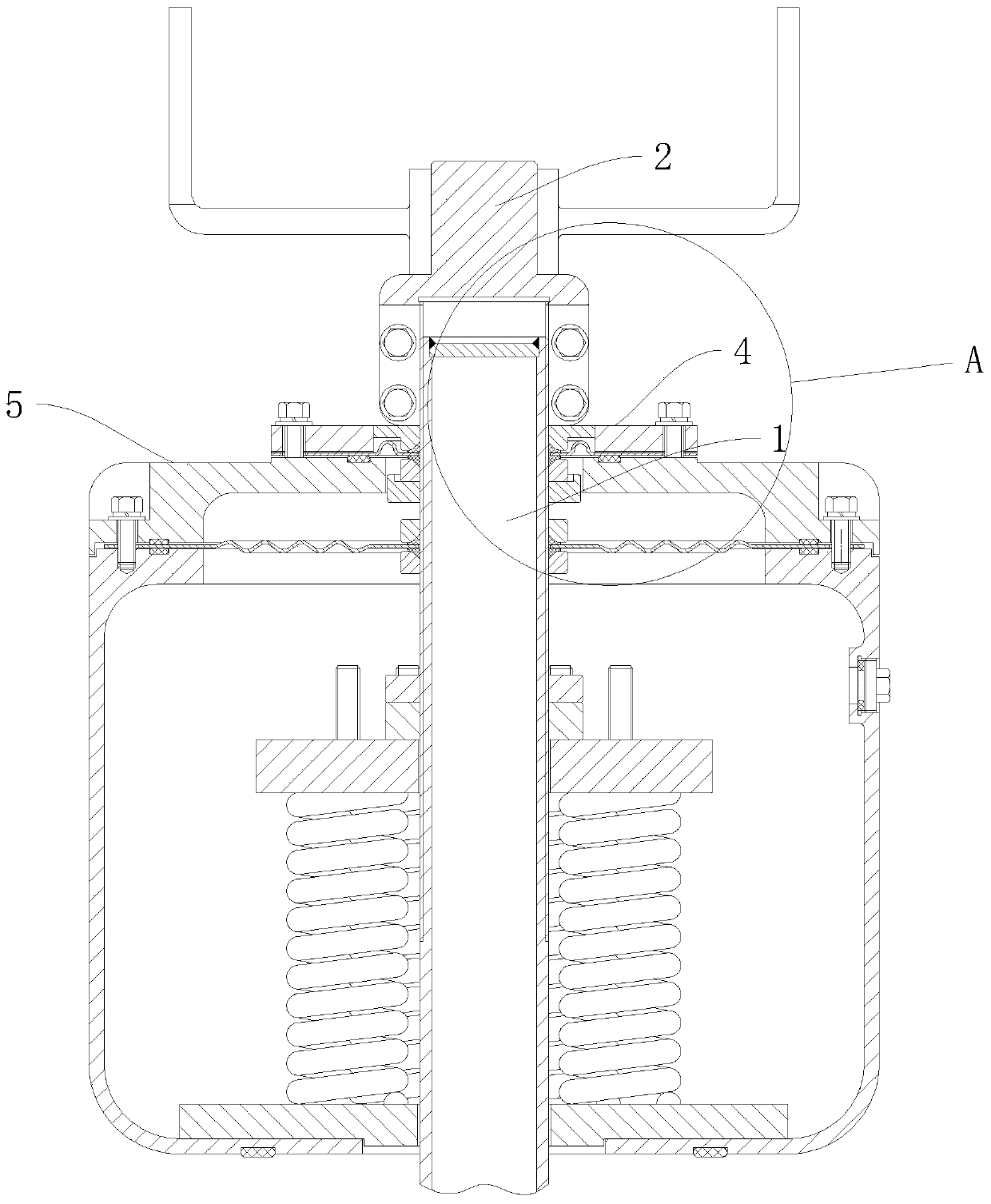

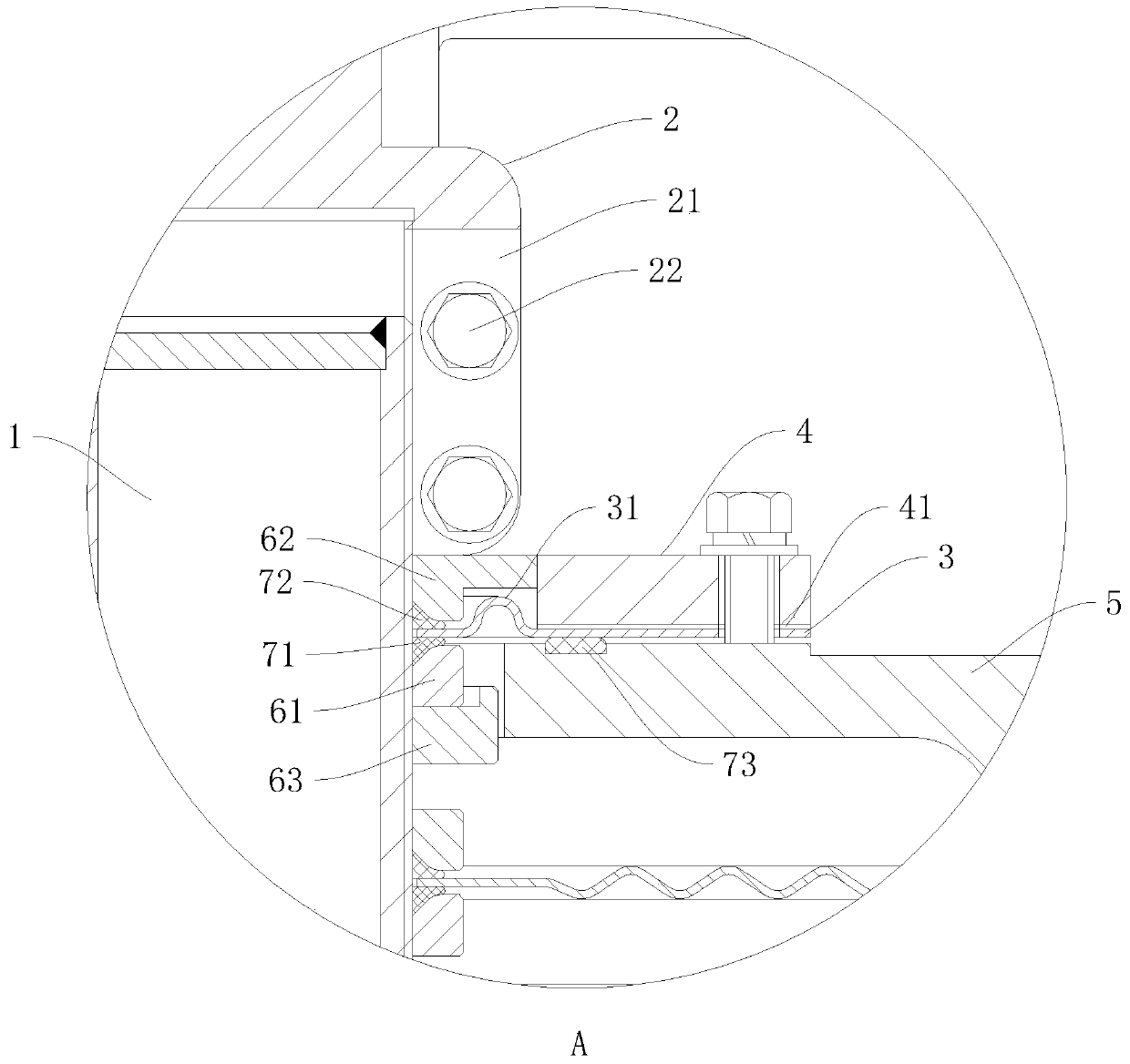

[0020] Such as figure 2 with image 3 As shown, an AC bushing structure includes a conductive tube 1, a conductive head 2 screwed to the head of the conductive tube 1, a cover plate 5, and an elastic plate 3 and a pressure ring 4 sequentially installed above the cover plate 5 to close the The top of the cover plate 5 prevents water from flowing into the inside.

[0021] The conductive head 2 adopts a Huff structure, that is, at the symmetrical place on both sides of the conductive head 2, there are symmetrically arranged slots 21, and the sides of the two slots 21 are provided with through holes through the conductive head 2. There are 2 on the side, 4 in total. When the conductive head 2 is screwed to the conductive pipe 1, the through hole is equipped with a screw 22 and a nut, so that the conductive head 2 clamps the conductive pipe 1, so that the conductive head 2 and the conductive pipe 1 can be connected even when the temperature of the conductive pipe 1 rises. Even ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com