Method of Transmutation of Transuranic Elements in Liquid Molten Salt Reactor

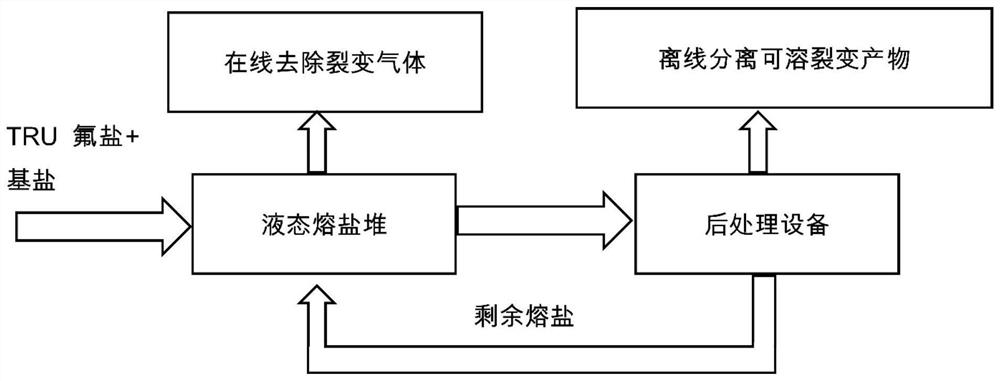

A technology for transuranic element and molten salt reactor, which is applied in the field of nuclear reactor engineering design, can solve the problems of high economic cost, high technical difficulty, low transmutation rate, etc., and achieves the effects of reducing reserves, high achievability, and reducing the difficulty of post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

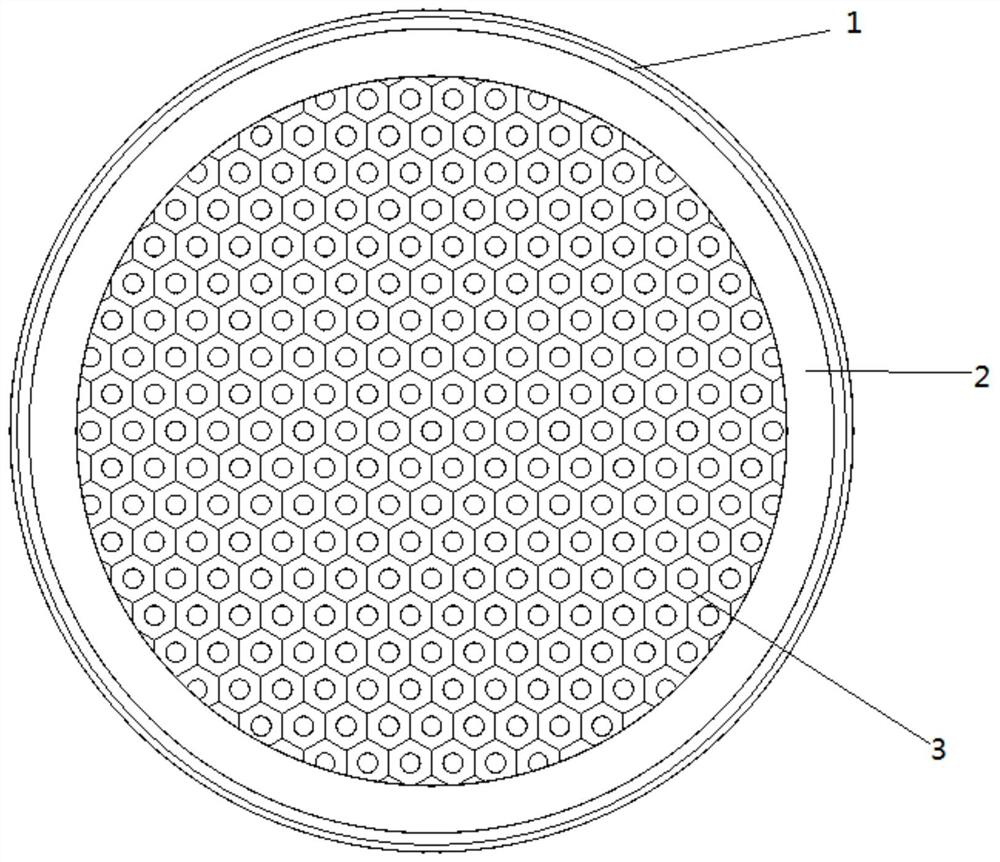

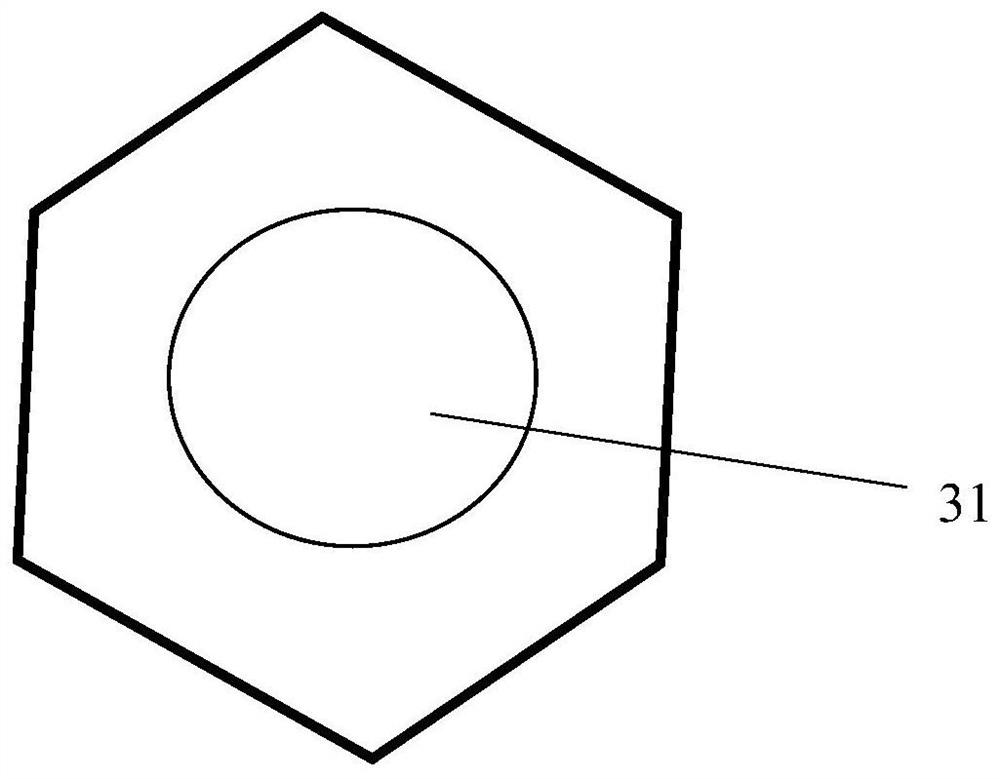

Embodiment 1

[0035] will be provided by TRUF 3 The molten salt composed of base salt is filled in the channel 31 of the graphite moderator component 3, TRUF 3 The initial molar percentage of the molten salt is 0.045%, and the volume ratio of the molten salt to the graphite moderator component 3 is 5%. Start the liquid molten salt reactor. During the operation, the fission gas is removed by blowing through the bubbling system. The blowing cycle is 30s, and the blowing efficiency is 100%. Add TRUF online 3 Maintain reactor criticality at 1. After the liquid molten salt reactor has been in operation for 24 years, the reactor is shut down, the molten salt is transferred to the reprocessing equipment, and the soluble fission products are separated by reduction extraction technology. At this time, the transmutation rate of transuranium elements takes the maximum value of 51.9%, TRUF 3 The molar percentage of the total amount of molten salt is 0.49%. Among them, the calculation method of the ...

Embodiment 2

[0037] TRUF 3 The initial molar percentage of the molten salt is 0.0271%, and the volume ratio of the molten salt to the graphite moderator component 3 is 10%. Other conditions are with embodiment 1. When the liquid molten salt reactor has been in operation for 15 years, the transmutation rate of transuranium elements takes a maximum value of 52.2%. At this time, TRUF 3 The molar percentage of the total amount of molten salt is 0.579%.

Embodiment 3

[0039] TRUF 3 The initial mole percentage of the molten salt is 0.0208%, and the volume ratio of the molten salt to the graphite moderator component 3 is 15%. Other conditions are with embodiment 1. When the liquid molten salt reactor has been in operation for 9.7 years, the transmutation rate of transuranium elements takes a maximum value of 50.9%. At this time, TRUF 3 The molar percentage of the total amount of molten salt is 0.384%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com