3D structured light module calibration method, storage medium and electronic device

A calibration method and structured light technology, applied in the field of computer vision, can solve the problems of difficulty in accurately obtaining the corresponding relationship between three-dimensional space points and three-dimensional space points, and difficulty in calibrating projection equipment, and achieve the effect of improving calibration accuracy and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

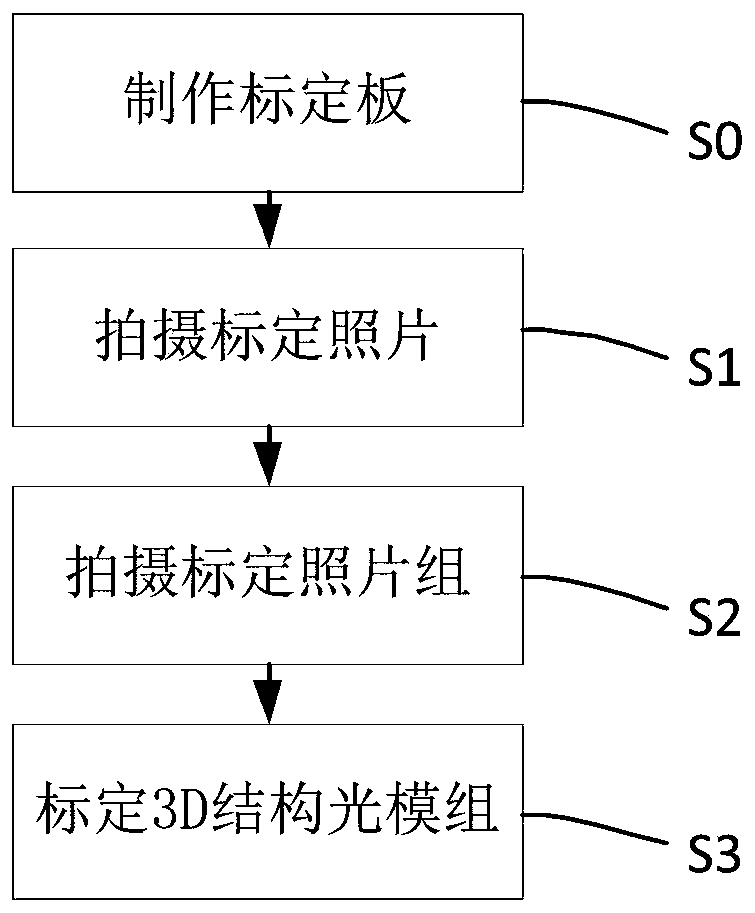

[0056] A method for calibrating a 3D structured light module, such as figure 1 shown, including the following steps:

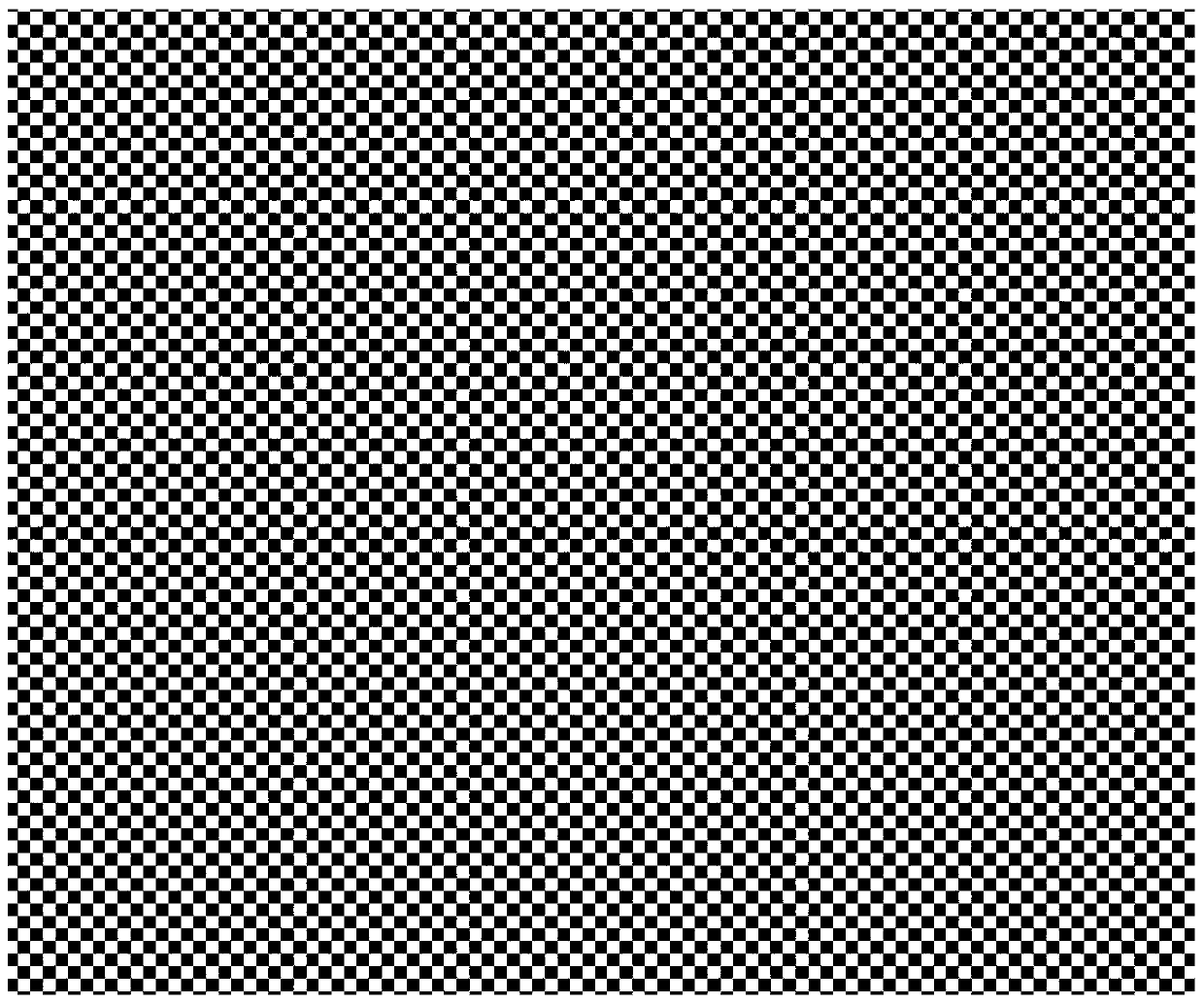

[0057] S0. Make a calibration board, print a checkerboard on a flat and hard white background calibration board, and the checkerboard covers the entire calibration board; figure 2 As shown, the shape of the checkerboard is square, the gray scale of the black grid in the checkerboard is adjustable, the size of the checkerboard is 12.5mm*12.5mm, and the size of the calibration plate is 1.2m*1.0m.

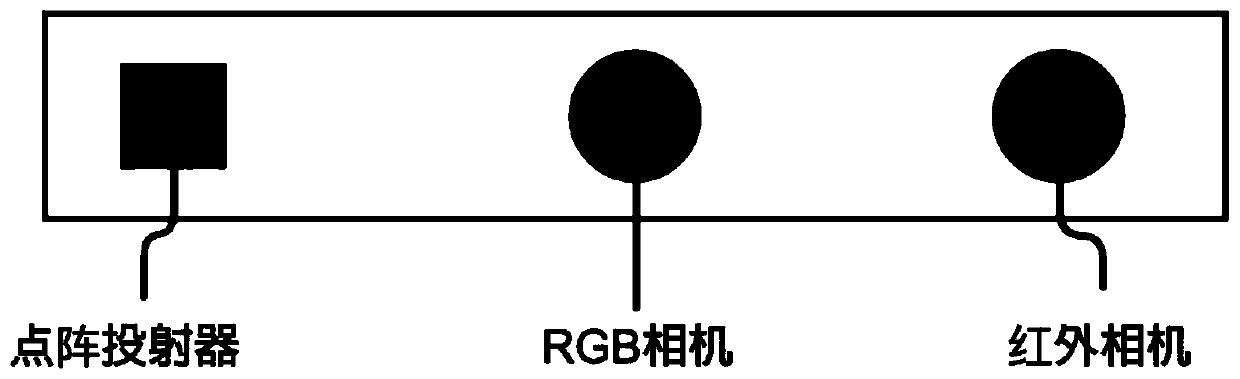

[0058] Such as image 3 As shown, the 3D structured light module hardware consists of a dot matrix projector, an RGB camera and an infrar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com