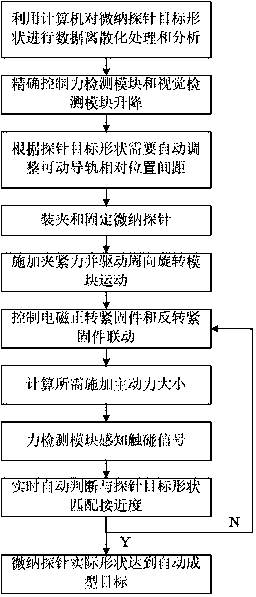

Micro-nano probe automatic molding device with real-time adjustable force, and control method

An automatic forming and probe technology, applied in the micro-nano field, can solve the problems of poor forming effect, single forming structure, low precision, etc., and achieve the effect of real-time and effective control of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

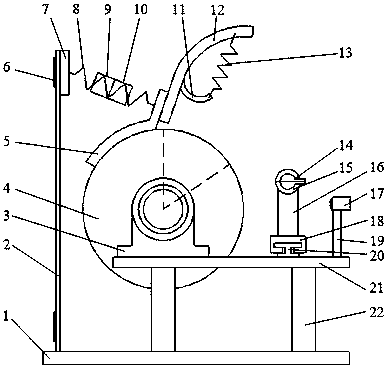

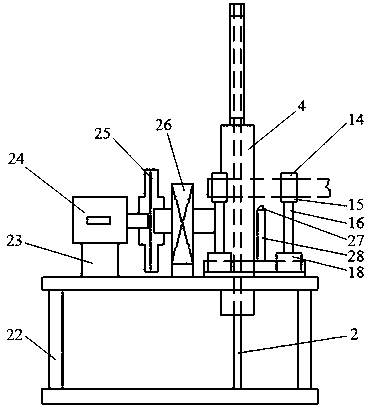

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

[0030] see figure 2 and 3 The micro-nano probe automatic molding device with real-time adjustable force includes a base plate 21, which is fixed on the base platform 1 parallel to the base plate 21 through a first support rod 22, and the base plate 21 is fixed with an actuator and a movable probe support mechanism.

[0031] The probe support mechanism includes a fixed guide rail 20 fixed on the base plate 21 and two movable slide rail parts 18 sliding on the fixed guide rail 20. The movable slide rail parts 18 are supported by the second support bar 16 to replace The probe support base 15 and the replaceable probe support base 15 provided on the two movable slide rails 18 jointly support a probe, and the replaceable probe support base 15 is hinged with a repl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com