Aviation sliding oil pump comprehensive testbed

A comprehensive test bench, oil pump technology, applied in pump testing, liquid variable capacity machinery, machines/engines, etc., can solve the problems of low work efficiency, unable to meet the speed of the oil pump at the same time, etc., to achieve high accuracy, reduce test Time and cost, the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

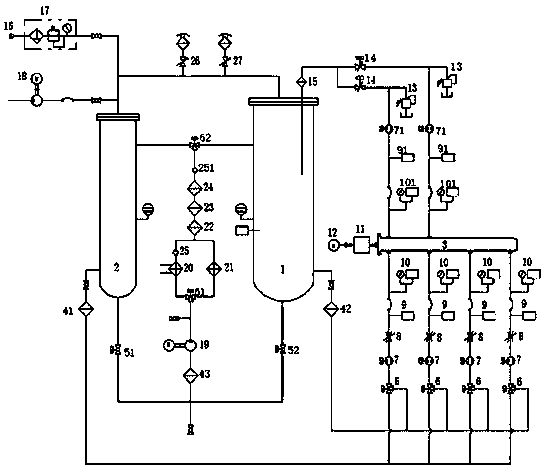

[0015] A comprehensive test bench for aviation oil pumps, comprising a metering fuel tank 2, a main oil tank 1, and a tested oil pump 3; figure 1 As shown, the tested lubricating oil pump 3 is connected to the side lower ends of the main fuel tank 1 and the metering fuel tank 2 respectively through 4 oil supply pipelines, and the tested lubricating oil pump 3 is connected to the top of the main fuel tank 1 through 2 oil return pipelines ; The metering oil tank 2 and the main oil tank 1 are respectively provided with a circulating oil circuit and an air pressure regulating circuit; the first pressure transmitter 10 and the first temperature transmitter are sequentially connected in series on the 4-way oil supply circuit 9. The regulating valve 8, the first flow meter 7, the first pneumatic three-way ball valve 6, the two ports of the four first pneumatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com