Three-glass two-cavity built-in rolling shutter window

A technology for rolling shutters and rolling shutters, applied in the field of rolling shutters, can solve the problem that the built-in rolling shutters cannot achieve a vacuum or hollow state, and achieve the effects of improving maintenance efficiency, improving assembly efficiency, and reasonable assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

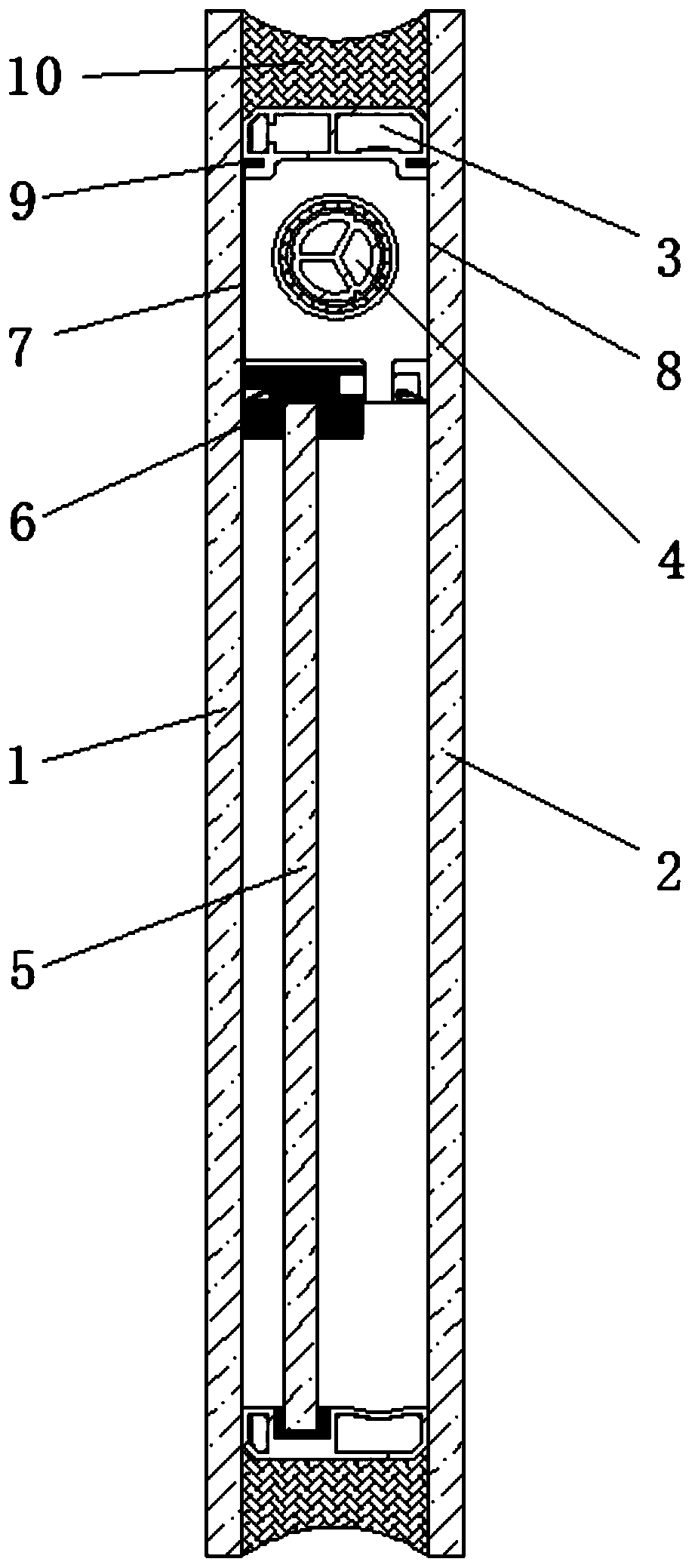

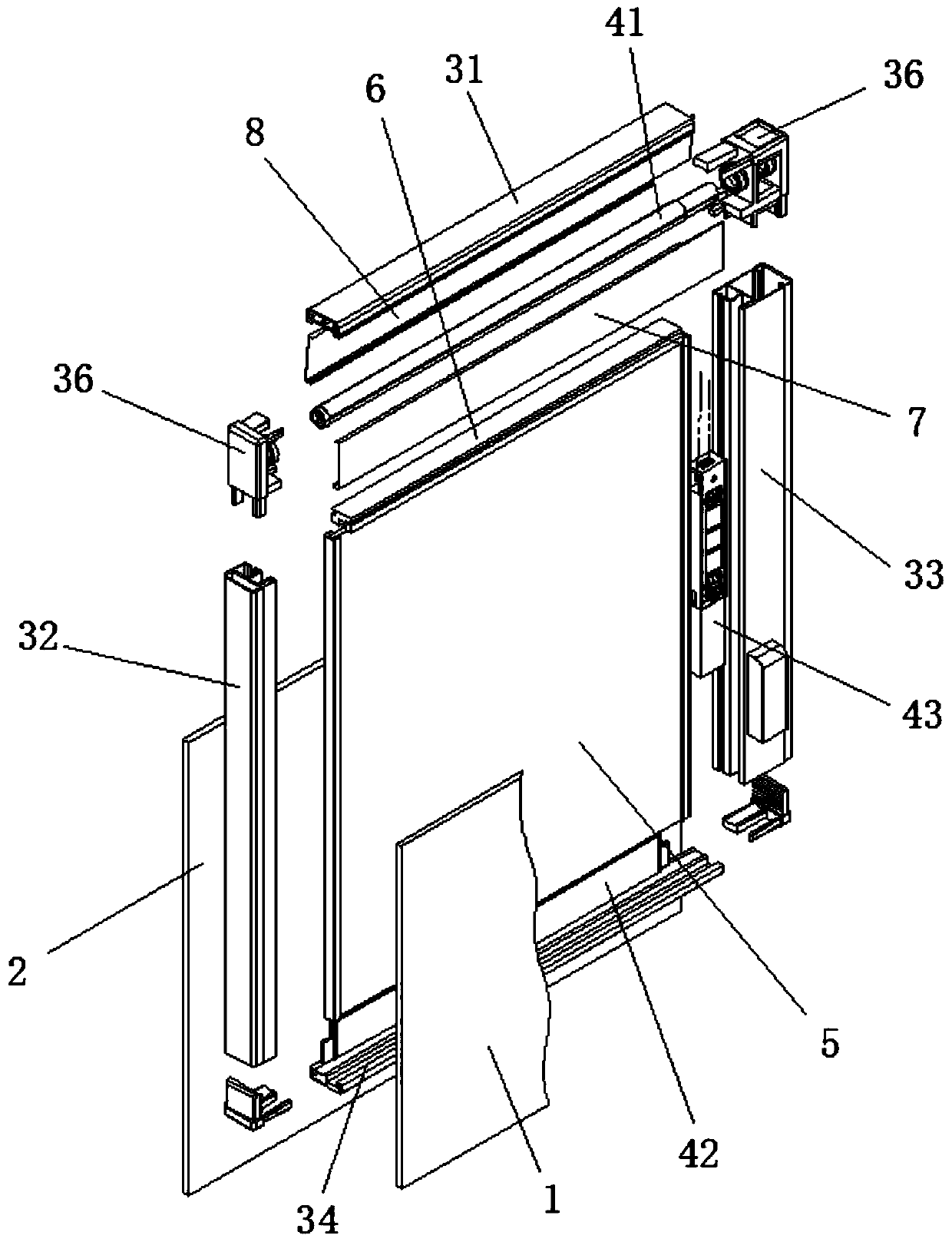

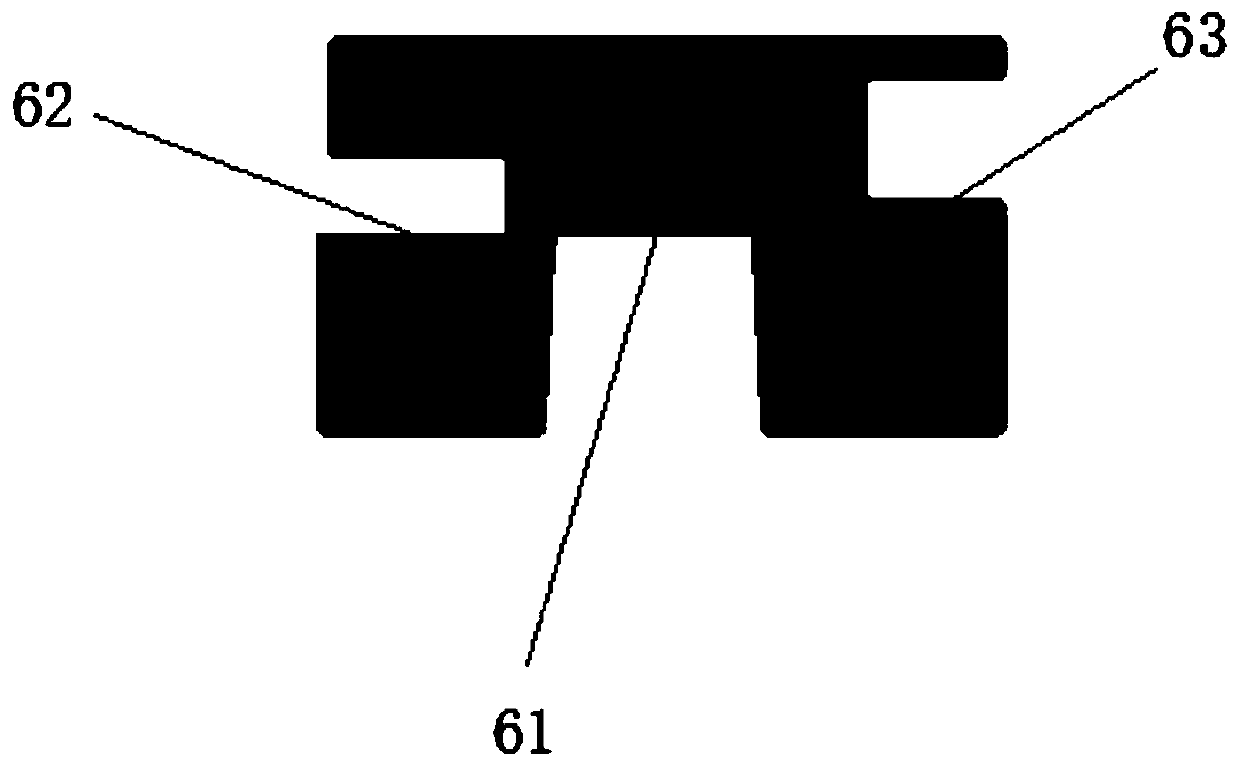

[0042] See Figure 1 to Figure 8 , the present invention has a first glass 1 and a second glass 2; a frame body 3 is sandwiched between the first glass 1 and the second glass 2; a built-in roller shutter mechanism 4 is provided on the frame body 3; the built-in roller shutter mechanism 4 includes a reel 41, a roller blind 42 wound on the reel 41, and a driving device 43 that realizes the rewinding or unwinding of the roller blind 42 by controlling the rotation of the reel 41; it is characterized in that the first glass 1 and the second glass 2 There is also an intermediate glass 5 between them; the edges around the intermediate glass 5 are hermetically connected to the frame body 3, a first sealed cavity is formed between the intermediate glass 5 and the first glass 1, and a sealed cavity is formed between the intermediate glass 5 and the second glass 2. The second sealed chamber; the reel 41 is rotatably arranged on the upper end of the frame body 3 , and the roller shutter 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com