Online printed matter screening system

A technology for printing and rejecting boards, applied in printing, printing presses, general parts of printing machinery, etc., can solve the problems of high labor cost, large amount of labor, low work efficiency, etc., and achieve the effect of ensuring effective rejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

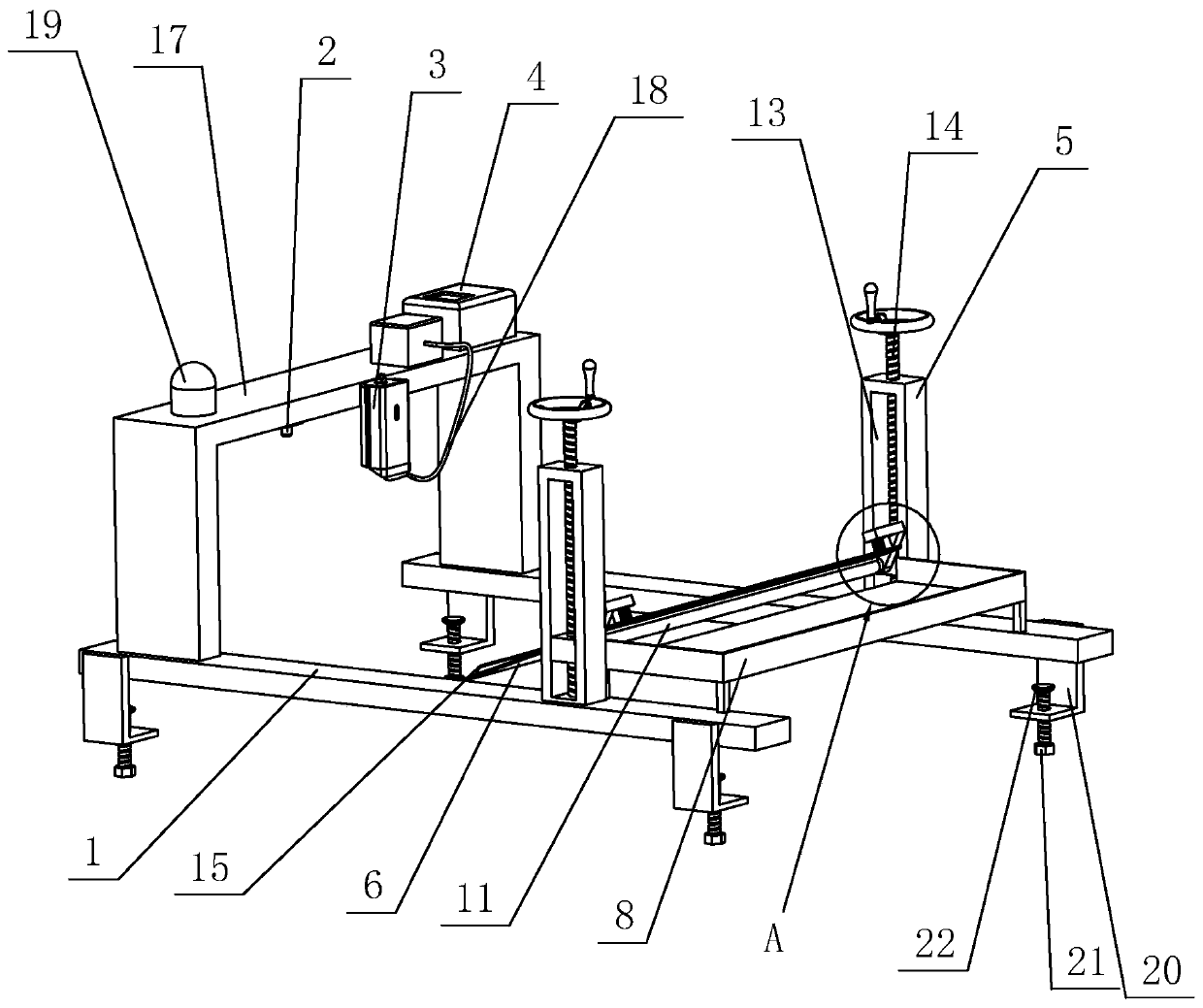

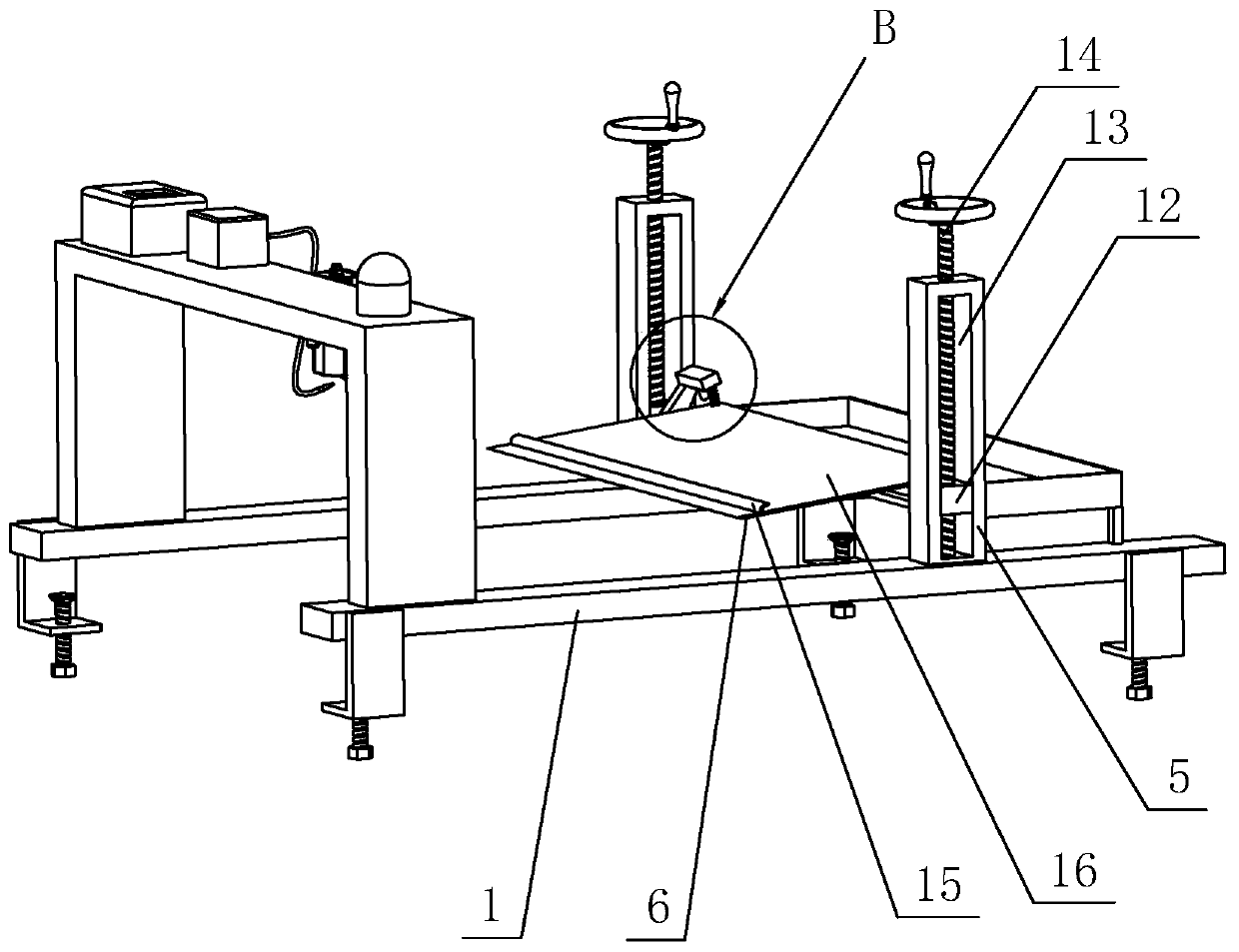

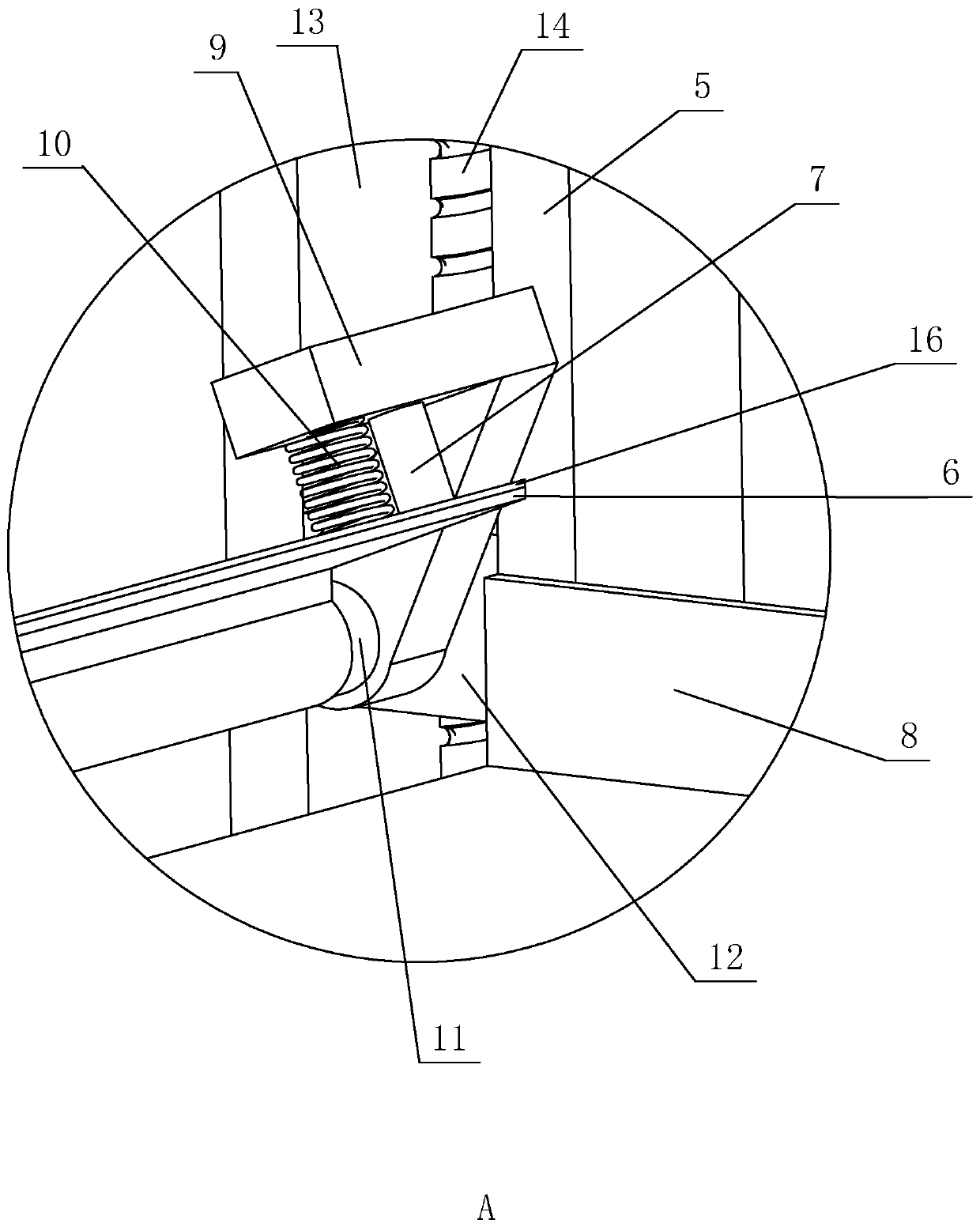

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0041] refer to figure 1 and image 3 , is an on-line screening system for printed matter disclosed in the present invention, which includes two bases 1 respectively fixed on the upper end surfaces of both sides of the printed matter transmission device, and the upper end surfaces of the two bases 1 are sequentially arranged along the transmission direction of the printed matter: a detection and control device, The rejecting device and the waste plate recycling device, the prosecuting device includes a gantry frame 17 that is jointly fixed on the upper end faces of the two bases 1, and the gantry frame 17 is fixedly connected with an image pickup device 3 with the lens vertically downward and communicates with the image pickup device 3. The connected controller 4, the image pickup device 3 is a common CCD industrial camera in the art; the rejecting device in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com