Small-bundle carbon fiber pre-soaking method

A tow carbon fiber and prepreg technology, applied in the field of carbon fiber preg, can solve the problems of small tow carbon fiber slippage, uneven prepreg, affecting guiding quality, etc., to prevent resin precipitation, improve prepreg quality, The effect of improving the quality of guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

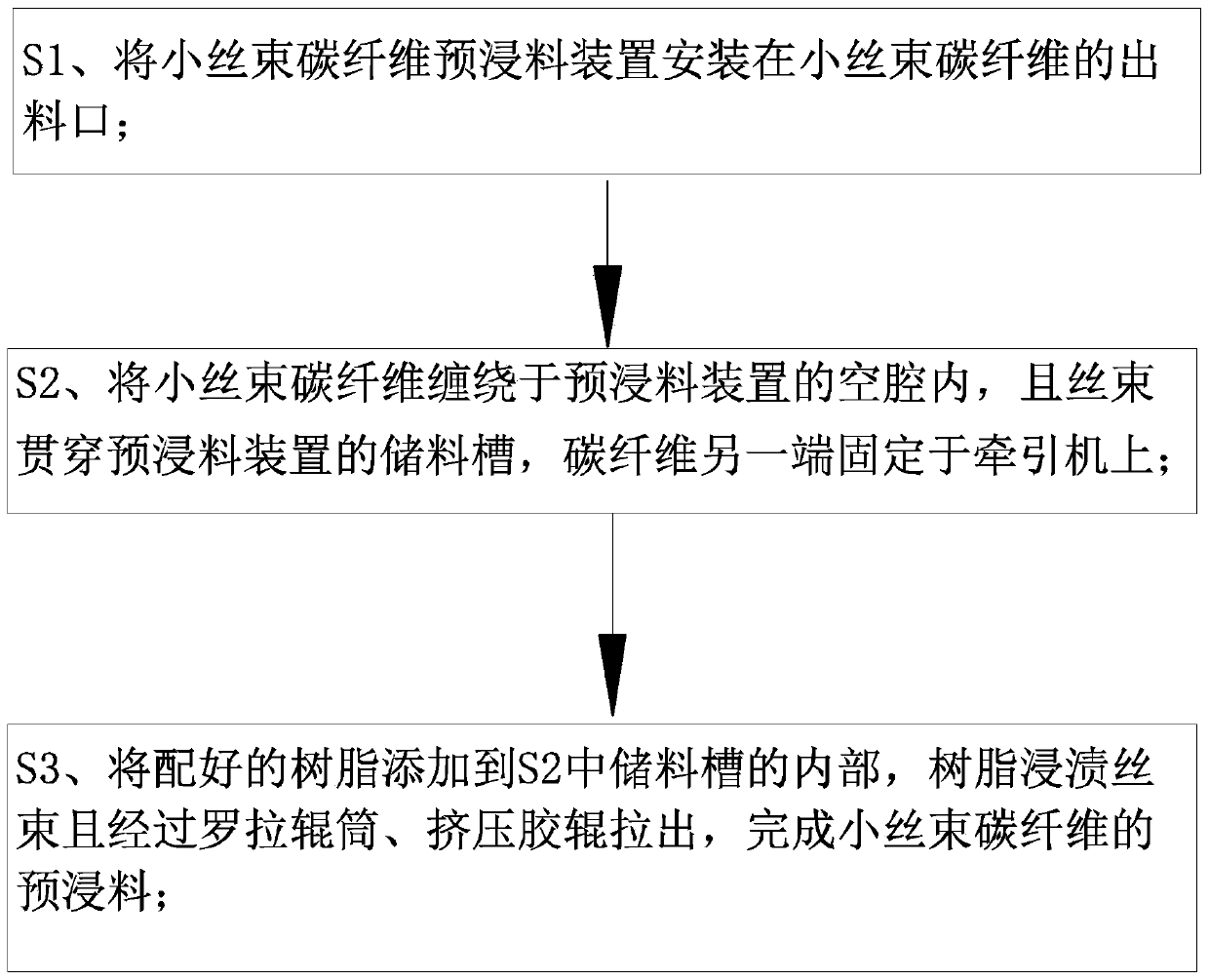

[0029] Such as Figure 1-Figure 9 Shown, a kind of small tow carbon fiber prepreg method of the present invention comprises the following steps:

[0030] S1. Install the small tow carbon fiber prepreg device at the discharge port of the small tow carbon fiber;

[0031] S2. Wrap the small tow carbon fiber in the cavity of the prepreg device, and the tow runs through the storage tank of the prepreg device, and the other end of the carbon fiber is fixed on the tractor;

[0032] S3. Add the prepared resin to the inside of the storage tank in S2, impregnate the tow with the resin and pull it out through rollers and extrusion rubber rollers to complete the prepreg of small tow carbon fibers; wherein,

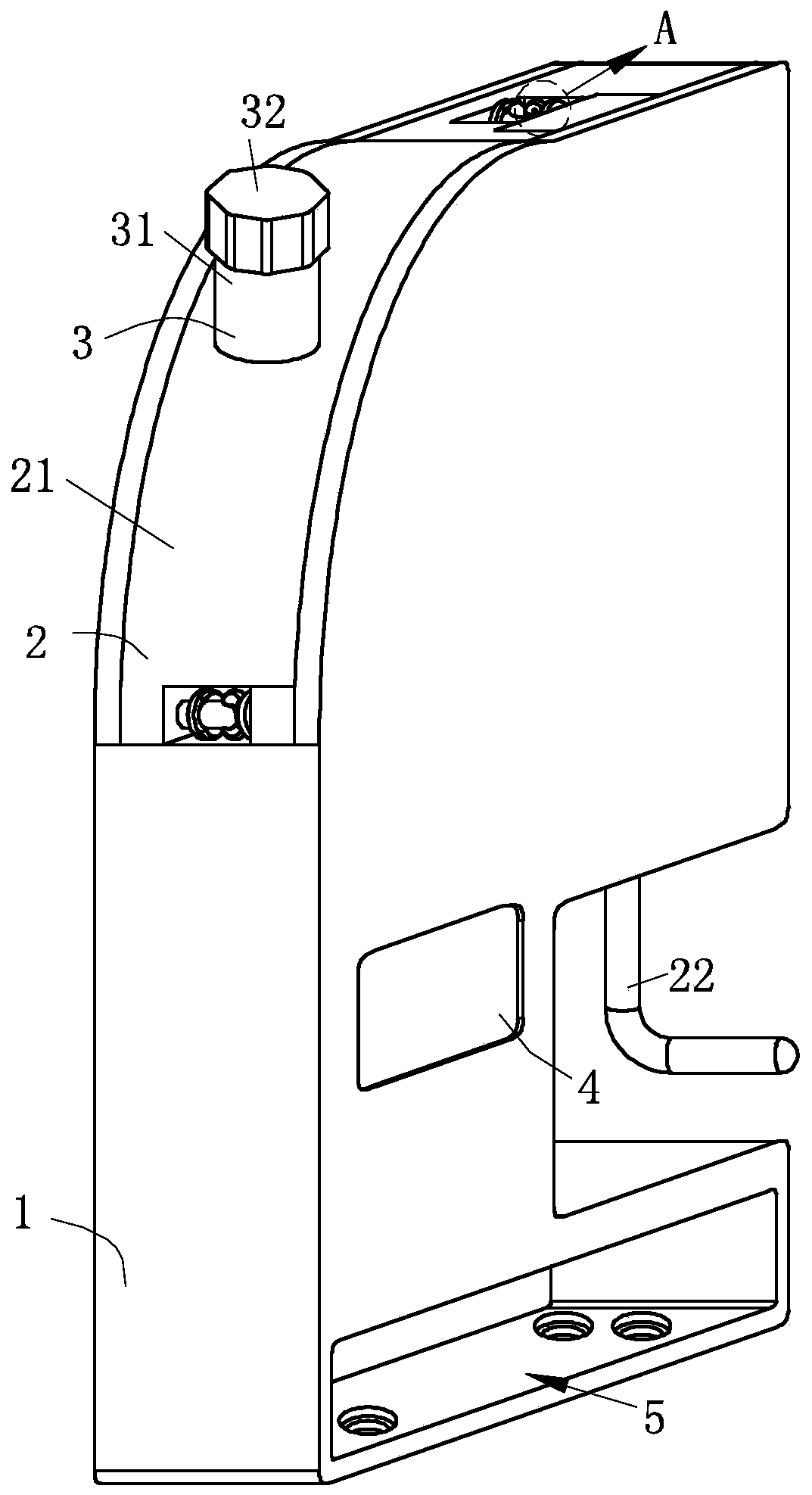

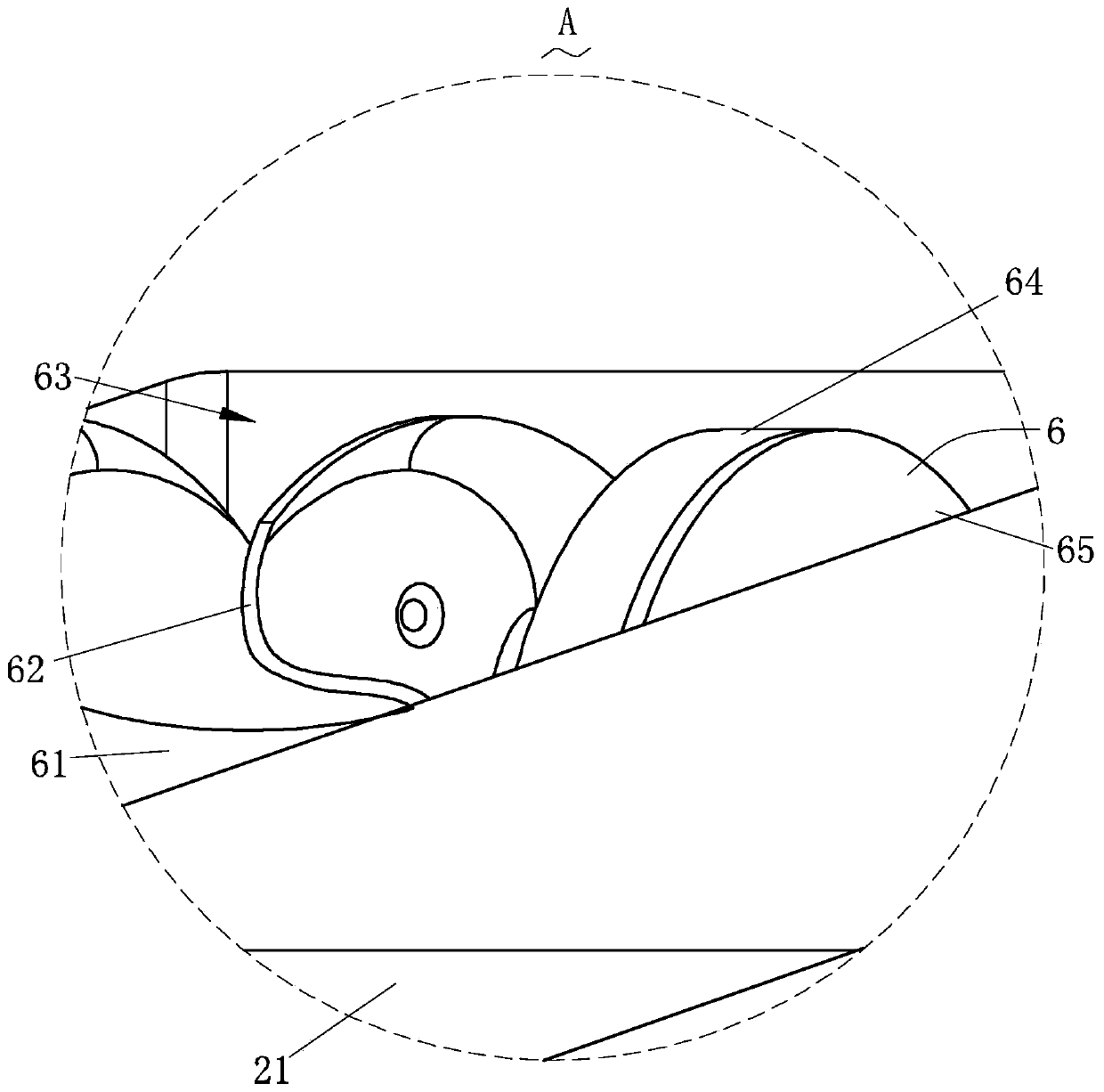

[0033] The small tow carbon fiber prepreg device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com