Fitting for connecting to at least one pipe and method for producing a connection

A technology for composite pipes and plastic pipes, which is applied in the field of joints for connecting with at least one pipe and for making connections, can solve the problems of extrusion wrinkles, lack of sealing, insufficient extrusion tool guidance, etc., and achieves less deformation and work. , Reduce the deformation work, the effect of firm and sealed connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the following descriptions of different embodiments according to the present invention, parts and elements having the same function and the same working principle have the same reference numerals, even though these parts and elements may be different in size and shape in different embodiments.

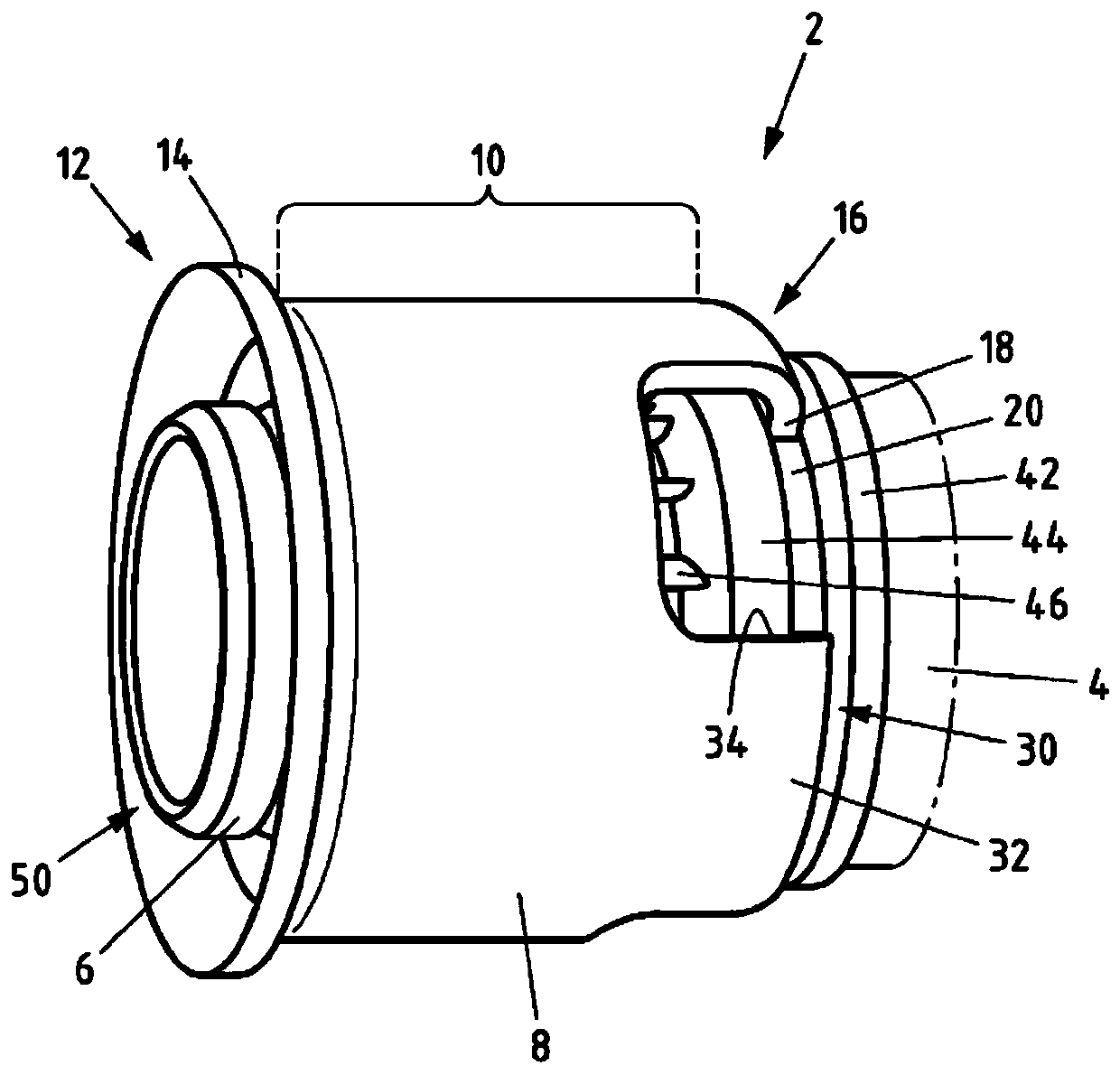

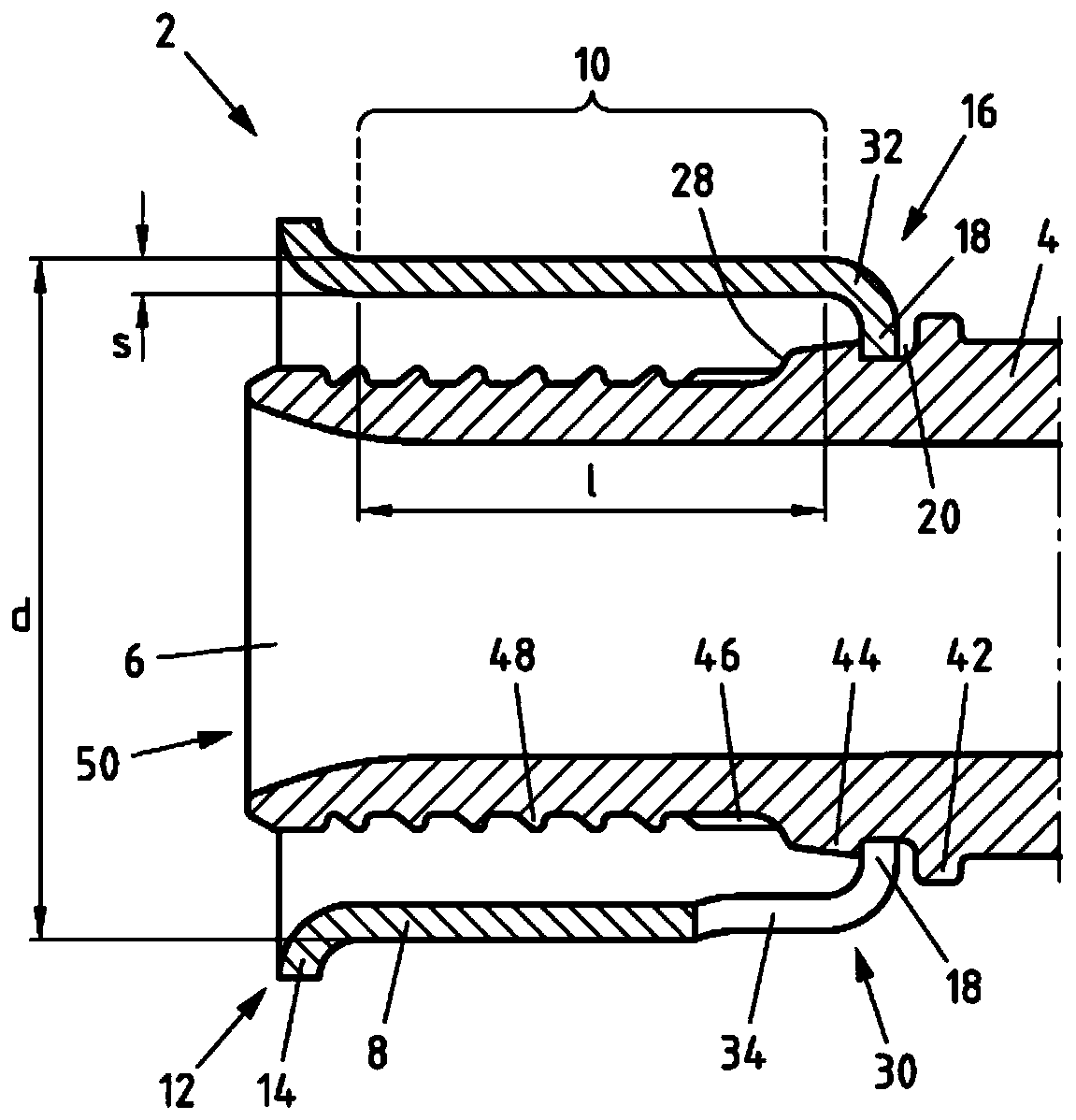

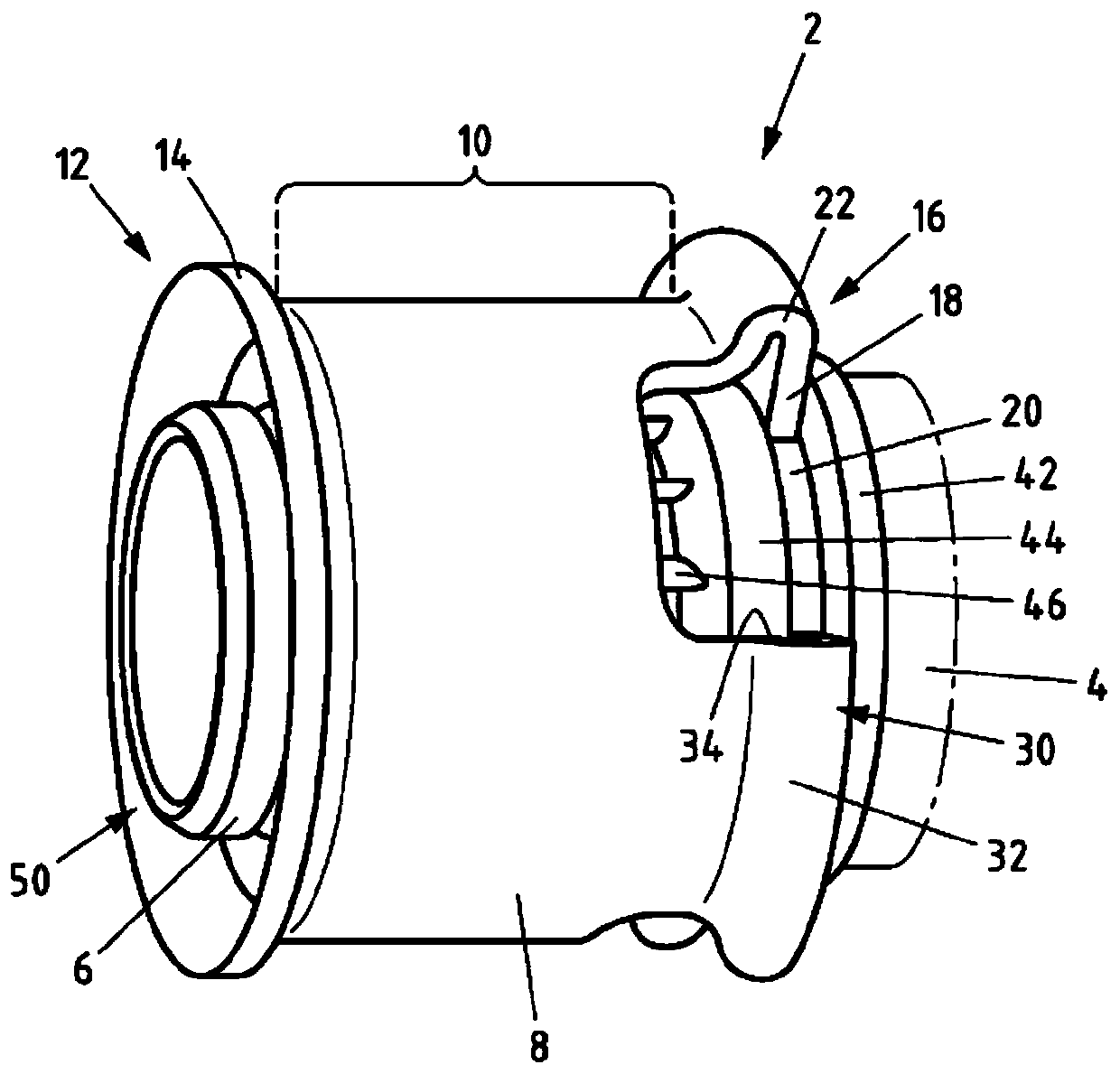

[0044] figure 1 and 2 A first embodiment of a connection 2 for connection to at least one pipe, in particular a plastic pipe or a plastic-metal composite pipe, is shown. The joint 2 has a base body 4, which is only shown at one end and at least one other, at figure 1 and 2 The other end extending to the right in the center is configured with the same connection geometry or another interface geometry.

[0045] A support 6 is provided which is connected to the main body 4 and is formed integrally here, so as to be inserted into a tube end (not shown here). For views with pipe ends see below Figures 11 to 13 Discussion in . Furthermore, a compression sleeve 8 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com