Large corrugated pipeline butt-joint device

A corrugated pipe and docking device technology, which is used in pipeline laying and maintenance, pipe/pipe joints/pipe fittings, hand-held tools, etc., can solve the problems of laboriousness, poor plug-in effect, heavy pipeline weight, etc., and achieve simple and convenient docking operation. , the effect of docking accuracy and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

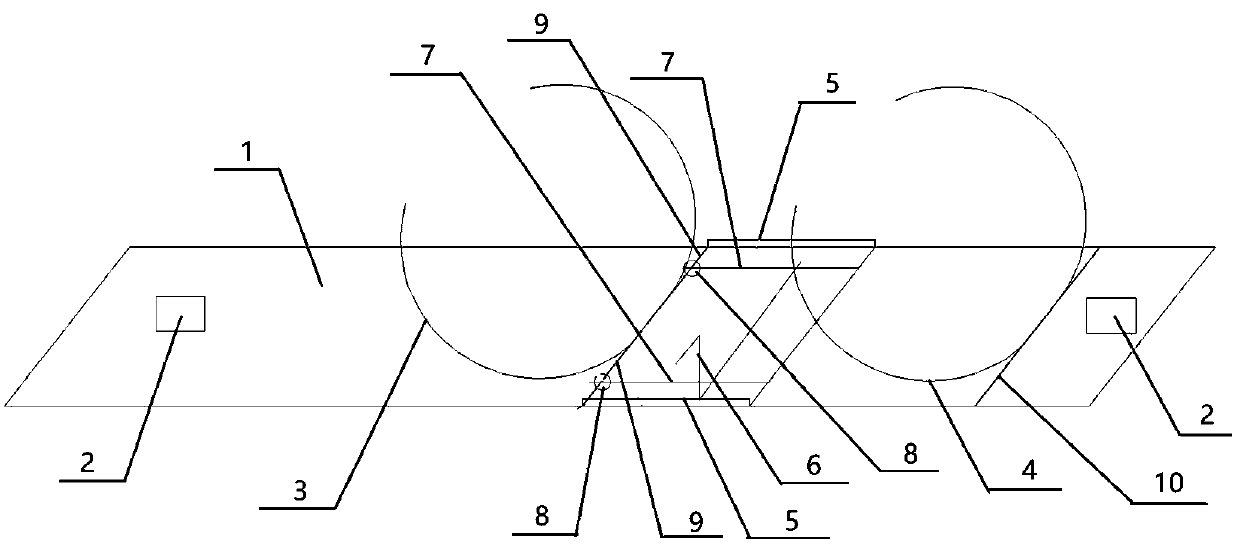

[0013] Such as figure 1 As shown, the said large-scale corrugated pipe butt joint device includes a wooden template cushion 1, an adjustable steel hoop 3, a fixed steel hoop 4, a movable bearing 9, a guide rail 5 and a manual labor-saving rocker 6;

[0014] The adjustable steel bar hoop 3 and the fixed steel bar hoop 4 are respectively located at the two ends of the wooden formwork cushion 1; the fixed steel bar hoop 4 is welded to the positioning steel bar 10, and the positioning steel bar 10 is fixed on by bolts or iron wires. The wooden formwork cushion; the adjustable steel hoop 3 is fixed on the movable bearing 9; the two ends of the movable bearing 9 are arranged on the guide rail 5, and the guide rail 5 is transversely arranged on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com