Crank balance adjusting device based on gravity

A technology of balance adjustment and crank, which is applied in the direction of inertial force compensation, production fluid, wellbore/well components, etc., and can solve problems such as high labor intensity, difficult management, and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

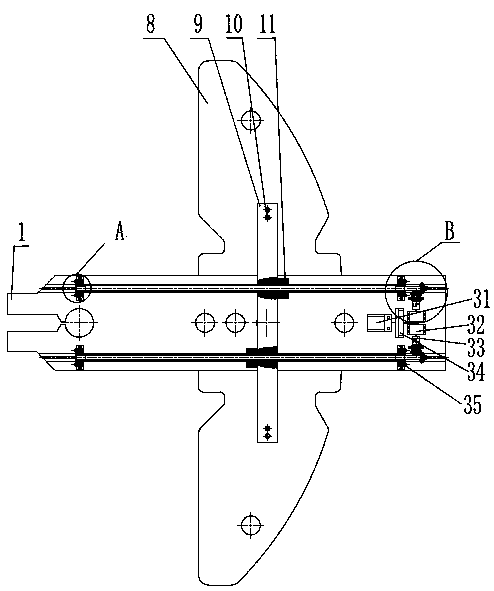

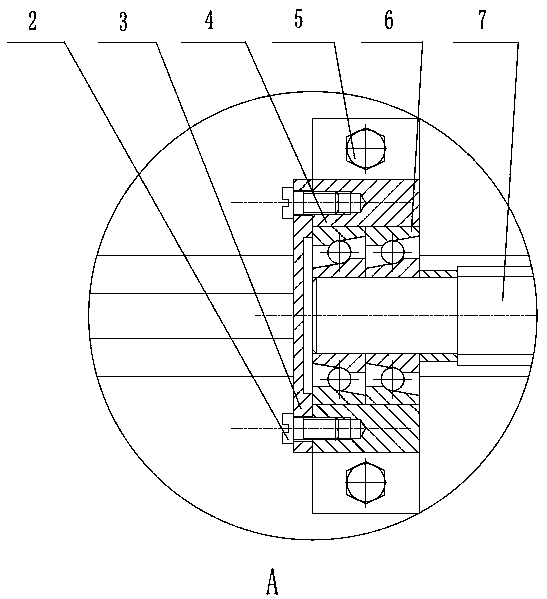

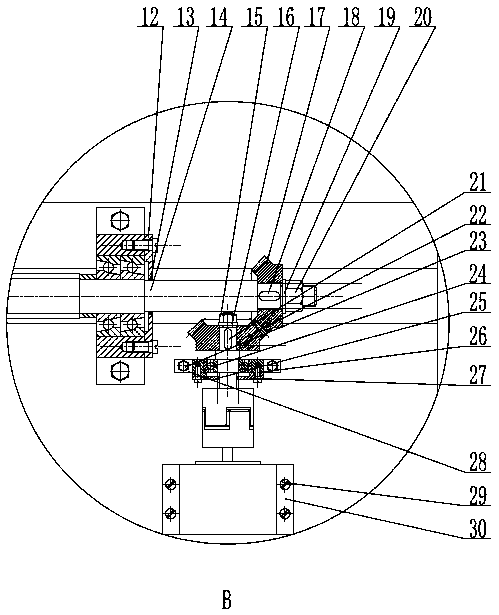

[0030] Firstly, the data processing module transmits the collected data to the industrial computer for analysis and processing, draws the dynamometer diagram through the dynamometer software, and the balance analysis software calculates the balance degree and judges the balance degree range, and calculates the balance weight (8) based on this The sliding displacement that needs to be generated on the crank (1), the direction and distance that the limiter (11) needs to move, the rotation direction of the lead screw (7), the rotation angle of the lead screw, the rotation direction of the stepper motor (32) and The angle of rotation is sent to the balance adjustment mechanism through the digital control software, and the balance adjustment is started.

[0031] After the corresponding parameters are calculated by the above data processing module, the gravity-based crank balance adjustment device starts to work, and the ratio of the maximum power of the downstroke motor of the pumpi...

Embodiment 2

[0033] Overbalance: When the pumping unit is in an overbalanced state, the motor P 下冲程max greater than P 上冲程max , now need to reduce the radius of the crank balance, that is, the balance weight (8) slides to the output shaft of the pumping unit, and utilizes the weight of the balance weight (8) to slide, and can only be adjusted in the downstroke. Firstly, the stepper motor (32) produces positive and negative rotations and the corresponding number of turns according to the parameters, driving the bevel gear set (17-22) to rotate, and the bevel gear set (17-22) drives the lower screw mandrel (7) to rotate, and the lower screw mandrel (7) Turn and then adjust the lower limiter (11) to reach the predetermined position; the crank (1) rotates slowly at a low speed, and when the crank (1) drives the balance weight (8) to rise to a certain height, the balance weight (8) will slide and slide The displacement is limited by the lower limiter (11) that reaches the predetermined position...

Embodiment 3

[0035] Underbalance: when the pumping unit is underbalanced, the motor P 下冲程max less than P 上冲程max, now need to increase the radius of the crank balance, that is, the balance weight (8) slides away from the output shaft of the pumping unit, and the weight of the balance weight (8) can only be adjusted on the upstroke. In the same way, the stepper motor (32) first drives the upper screw (7) to reach the predetermined position, and when the crank (1) drives the balance weight (8) down to a certain height, the balance weight (8) slides, and the sliding displacement is reached by The upper limiter (11) at the predetermined position is limited; before entering the downstroke, turn the lower screw rod (7) to drive the lower limiter (11) to be close to the link mechanism (9) to prevent the balance weight (8) Due to gravity, it slides in the direction of the output shaft of the pumping unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com