Method for producing scented fabric with unidirectional moisture conducting function

A technology of one-way moisture guide and production method, which is applied in the field of textiles, can solve the problems of fabrics that are easy to leave odor, not resistant to washing, and ammonia nitrogen substances that are easy to breed bacteria, so as to achieve the effects of not easy to fall off, prevent bacterial growth, and improve bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

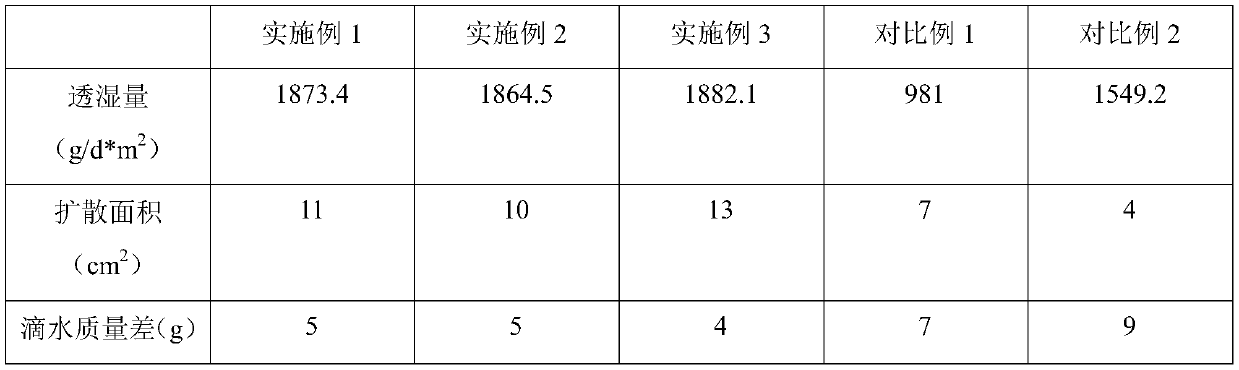

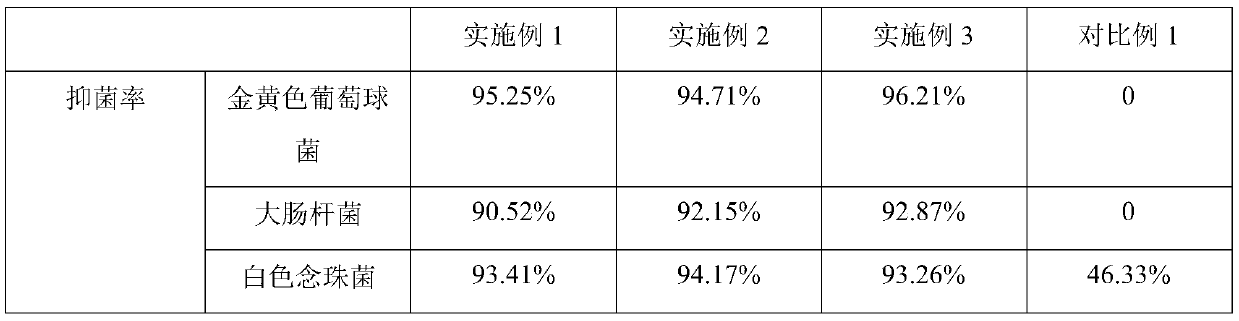

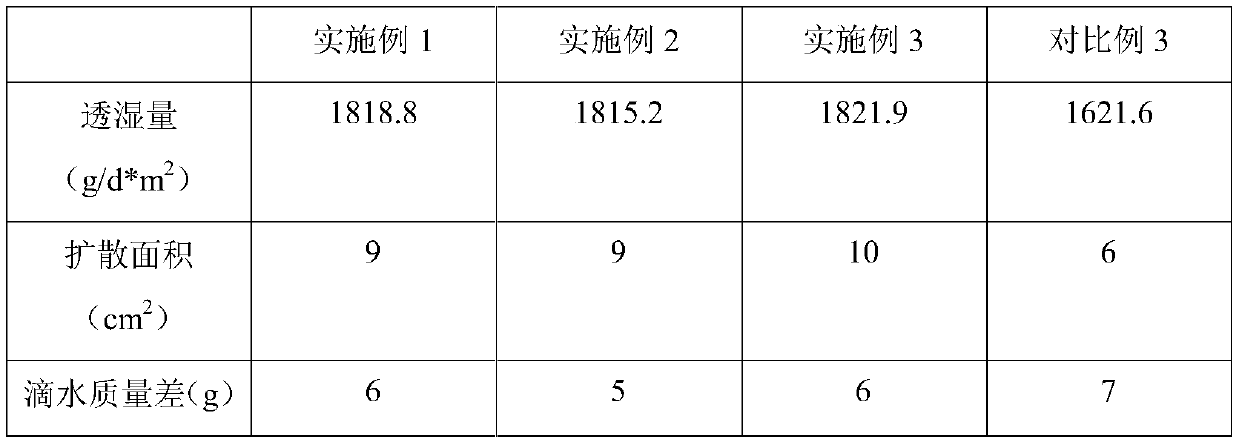

Examples

Embodiment 1

[0020] A method for making a fragrance-containing fabric with a unidirectional moisture-wicking function, comprising the following steps:

[0021] Step 1: Use core-spun yarn, hydrophilic polyester fiber, and cotton fiber to weave a three-layer gray fabric, the core-spun yarn is woven to form the inner layer of the gray fabric, hydrophilic polyester fiber is woven to form the middle layer of the gray fabric, and cotton fiber is woven Constitute the outer layer of the gray cloth, wherein the core yarn of the core-spun yarn is polyacrylonitrile fiber with special-shaped cross-section, the outer wrapping part of the core-spun yarn is bamboo pulp fiber, the weight percentage of the core-spun yarn in the gray cloth is 40%, hydrophilic polyacrylonitrile The weight percentage of ester fiber is 40%, the weight percentage of cotton fiber is 20%, and the cross-sectional shape of polyacrylonitrile fiber is cross;

[0022] Step 2. Soak the gray cloth in water at a bath ratio of 1:20 at a v...

Embodiment 2

[0027] A method for making a fragrance-containing fabric with a unidirectional moisture-wicking function, comprising the following steps:

[0028] Step 1: Use core-spun yarn, hydrophilic polyester fiber, and cotton fiber to weave a three-layer gray fabric, the core-spun yarn is woven to form the inner layer of the gray fabric, hydrophilic polyester fiber is woven to form the middle layer of the gray fabric, and cotton fiber is woven Constitute the outer layer of the gray cloth, wherein the core yarn of the core-spun yarn is polyacrylonitrile fiber with special-shaped cross-section, the outer wrapping part of the core-spun yarn is bamboo pulp fiber, the weight percentage of the core-spun yarn in the gray cloth is 40%, hydrophilic polyacrylonitrile The weight percentage of ester fiber is 40%, the weight percentage of cotton fiber is 20%, and the cross-sectional shape of polyacrylonitrile fiber is triangular;

[0029] Step 2. Soak the gray cloth in water at a bath ratio of 1:27 a...

Embodiment 3

[0034] A method for making a fragrance-containing fabric with a unidirectional moisture-wicking function, comprising the following steps:

[0035] Step 1: Use core-spun yarn, hydrophilic polyester fiber, and cotton fiber to weave a three-layer gray fabric, the core-spun yarn is woven to form the inner layer of the gray fabric, hydrophilic polyester fiber is woven to form the middle layer of the gray fabric, and cotton fiber is woven Constitute the outer layer of the gray cloth, wherein the core yarn of the core-spun yarn is polyacrylonitrile fiber with special-shaped cross-section, the outer wrapping part of the core-spun yarn is bamboo pulp fiber, the weight percentage of the core-spun yarn in the gray cloth is 40%, hydrophilic polyacrylonitrile The weight percentage of ester fiber is 40%, the weight percentage of cotton fiber is 20%, and the cross-sectional shape of polyacrylonitrile fiber is Y shape;

[0036] Step 2. Soak the gray cloth in water at a bath ratio of 1:24 at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com