Conveniently-used numerically-controlled machine tool tooling fixture

A CNC machine tool and clamping technology, applied in the field of CNC machine tools, can solve problems such as fixing and troublesome operation, and achieve the effects of easy installation and disassembly, adjustment of clamping use height, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

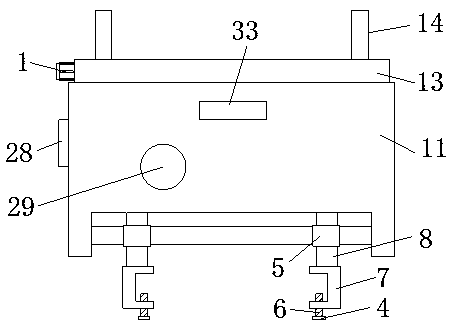

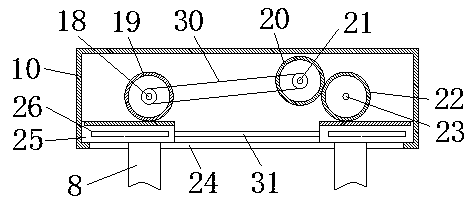

[0022] Embodiment: two first splints 7 are placed on both sides of the operation platform of the CNC machine tool, and then controlled by the switch 33, the second positive and negative motor 29 is started, and the second positive and negative motor 29 works to drive the drive shaft 18 to rotate. The driving shaft 18 drives the first gear 19 to rotate, and the rotating driving shaft 18 drives the first rotating shaft 21 to rotate through the first transmission wheel, the second transmission wheel and the transmission belt 30, and the rotating first rotating shaft 21 drives the second gear 20 to rotate. The second gear 20 drives the third gear 22 to rotate, and the rotating first gear 19 and the third gear 22 drive the two racks 25 to move toward each other, and then drive the two clamping rods 8 to move toward each other, and then drive the two first splints 7 to move toward each other Clamp both ends of the operating platform of the CNC machine tool through the clamping groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com