Small paper umbrella and making process thereof

A technology for making crafts and paper umbrellas, applied in umbrellas, travel goods, clothing, etc., can solve the problems that umbrellas cannot be opened and closed, the umbrella structure is too simplified, and the manufacturing process is cumbersome. The effect of simplicity and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with specific embodiment, this case is described in further detail.

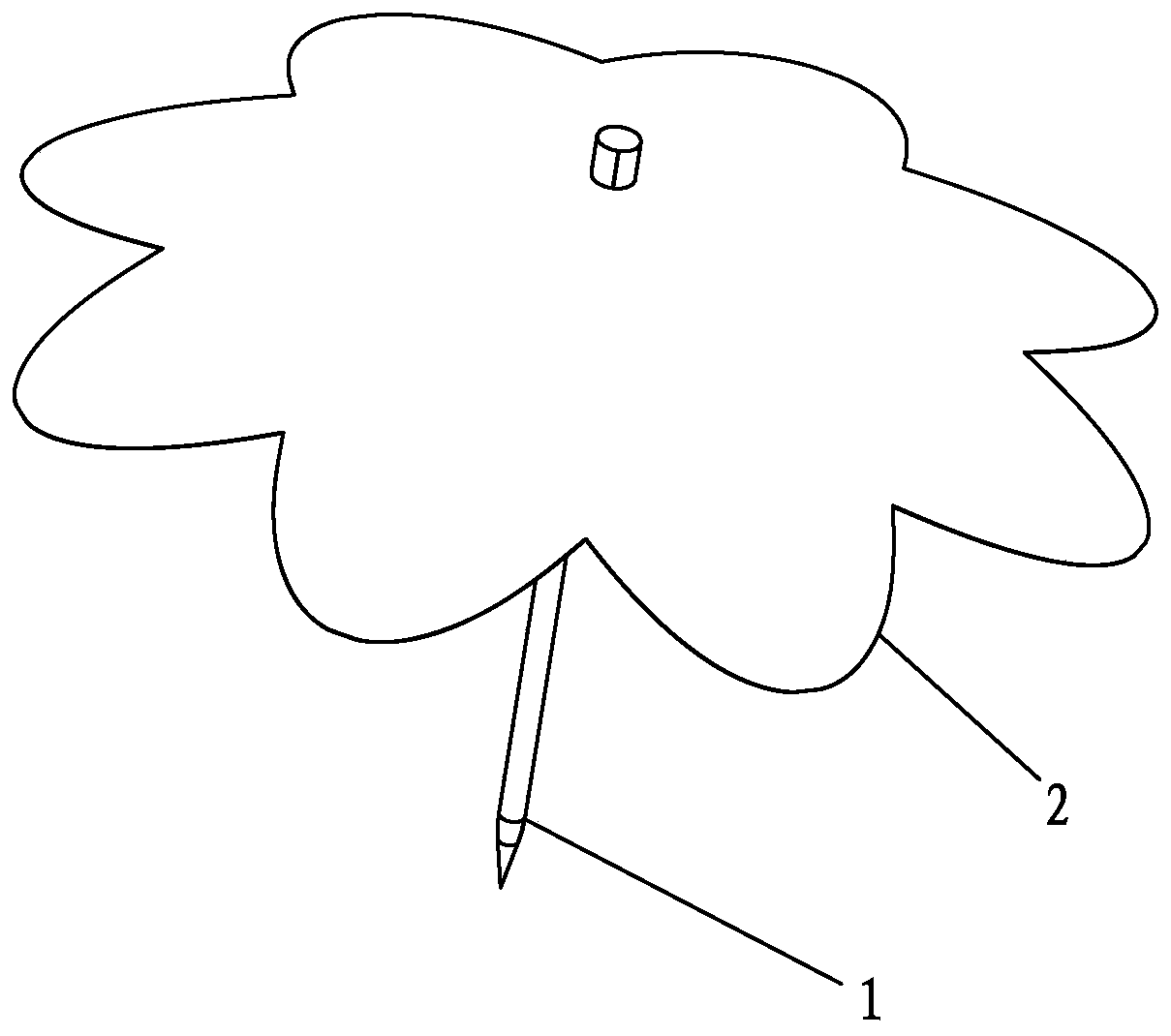

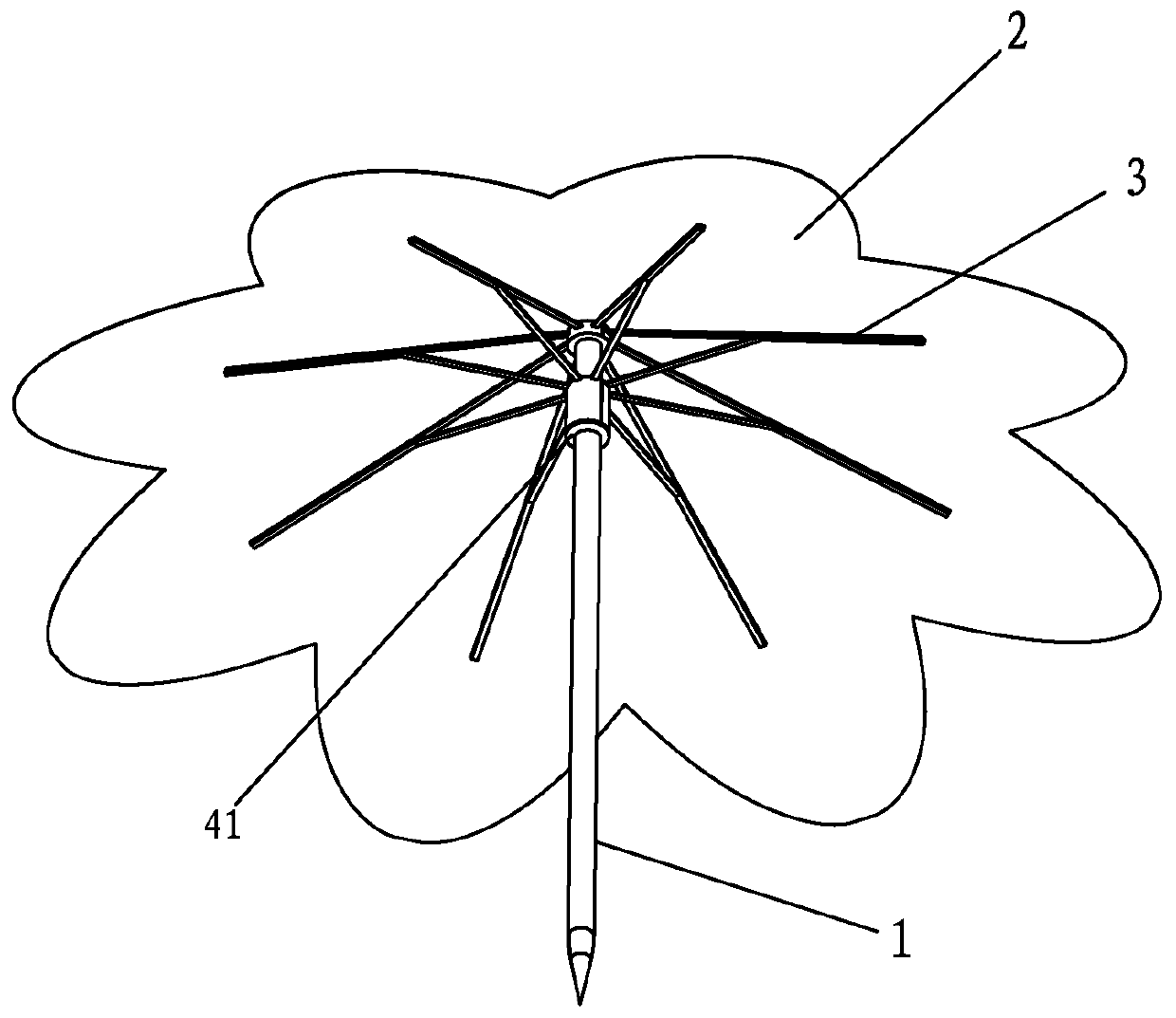

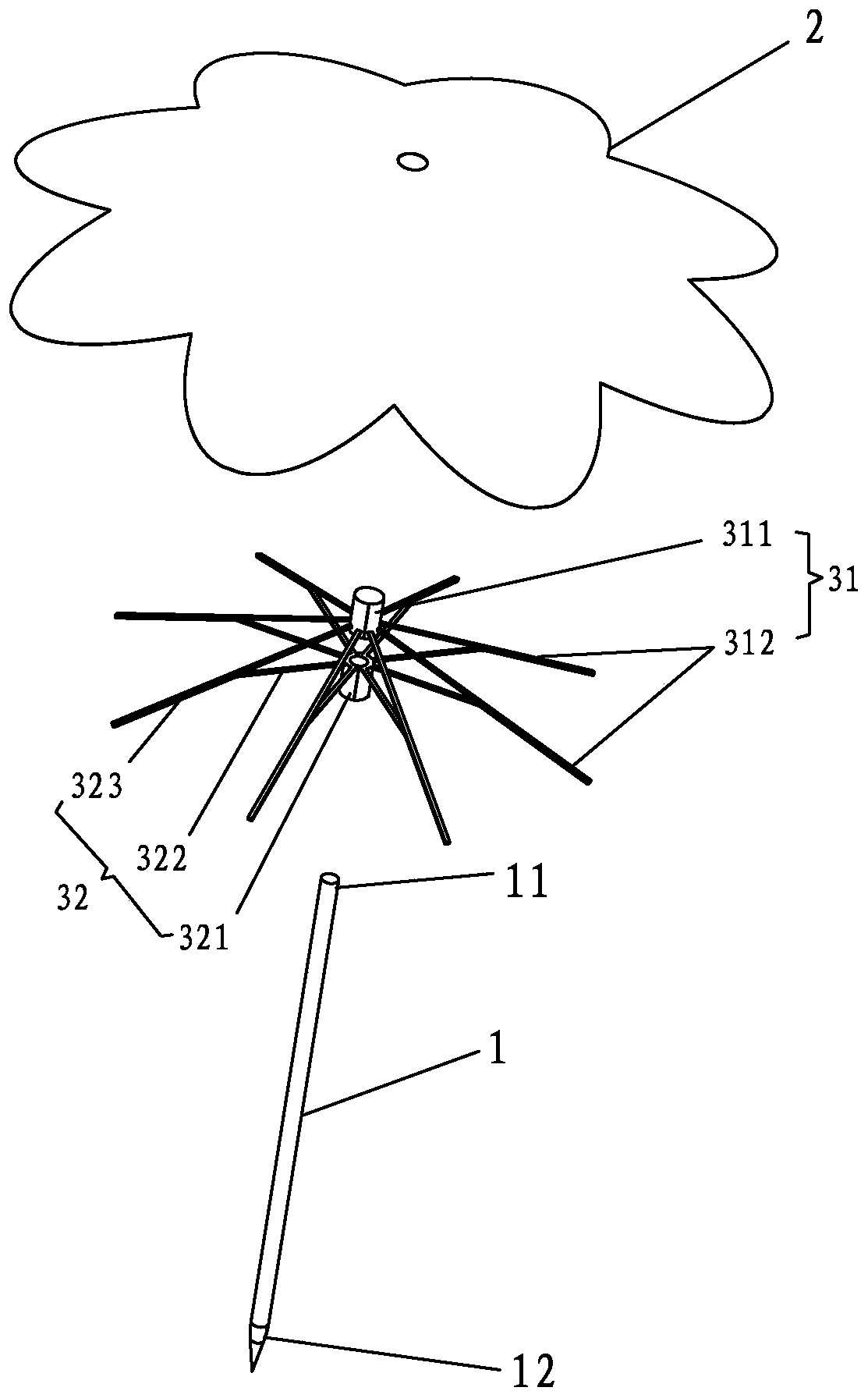

[0042] This case involves a small paper umbrella, such as Figure 1-7 As shown, it mainly includes umbrella pole 1, paper umbrella surface 2 and umbrella frame 3 three parts.

[0043] The umbrella pole 1 can be in the shape of a slender rod, and the material can have many choices, such as wood or plastic. This case provides specific embodiment to adopt wooden sign. The two ends of the umbrella pole 1 are respectively designed as a flat head and a pointed end 12, the flat head is used as the upper end 11 of the umbrella pole 1, and the pointed end 12 is used as the lower end of the umbrella pole 1, which is beneficial to the insertion and application of small paper umbrellas. The paper umbrella surface 2 is an umbrella surface modeling structure cut from paper, which can change colors and patterns as required to enrich the design of the small paper umbrella.

[0044] The umbrell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com