Method for evaluating thermal runaway risk degree of chemical process

A process and risk technology used in assessing the risk of thermal runaway in chemical processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

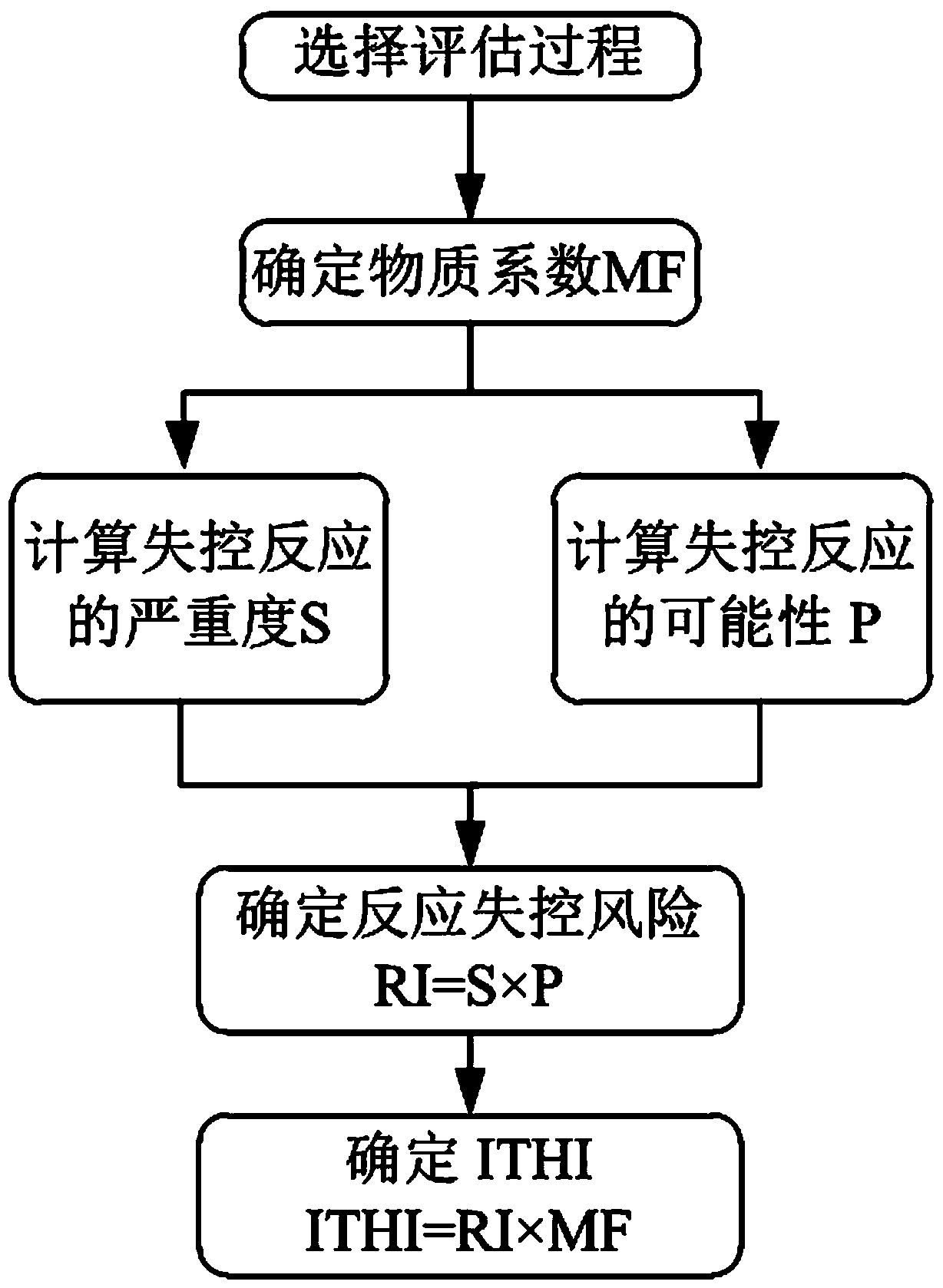

[0064] Attached below figure 1 And specific embodiment, the method of the present invention is described in detail.

[0065] Refer to attached figure 1 , the inventive method comprises the steps:

[0066] Step 1. Collect thermal hazard data of raw materials, products and reaction process;

[0067] Obtain the thermal decomposition data of raw materials and products involved in the process, as well as the thermal runaway hazard characteristic data of the reaction process through experimental tests or literature review, so as to provide data support for subsequent evaluation;

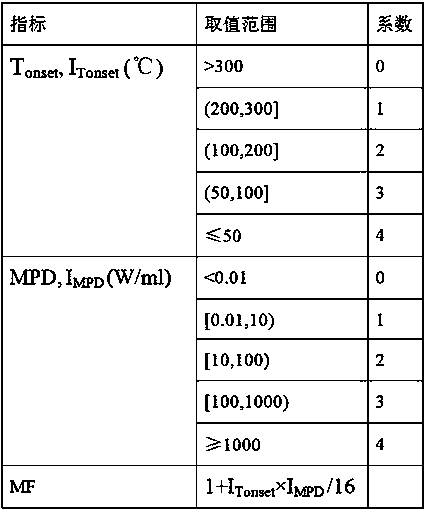

[0068] Step 2, determine the material coefficient MF;

[0069] The material coefficient MF is determined by the starting decomposition temperature of the material (T onset ) and the maximum exothermic power (MPD), which reflect the risk of thermal decomposition of the substance. T onset It refers to the temperature at which a substance begins to decompose. The lower the temperature, the higher the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com