Displacement monitoring device and method based on optical fiber bending loss

A bending loss and displacement monitoring technology, applied in the field of sensors, can solve the problems of complex preparation process and high testing cost of displacement sensors, and achieve high precision and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

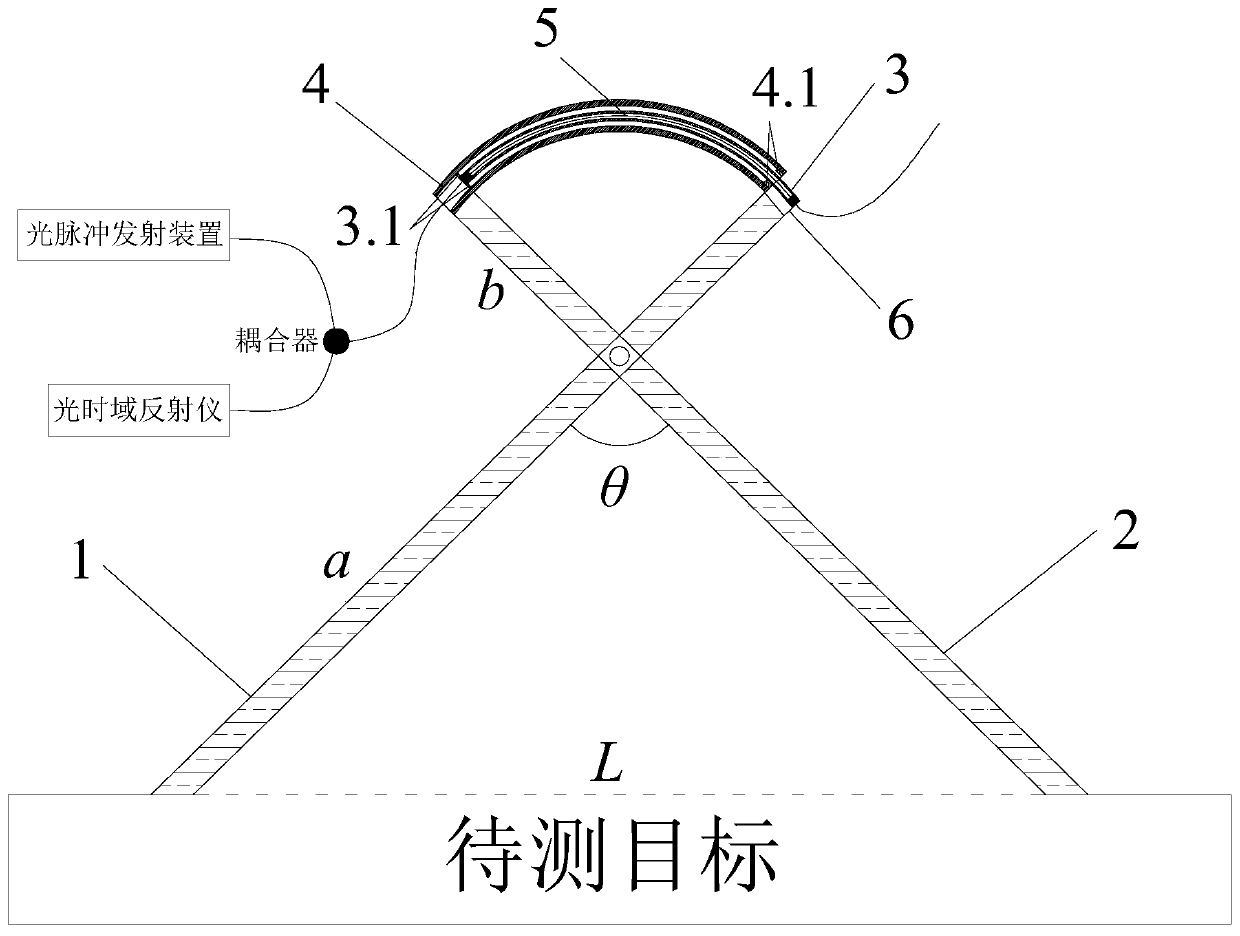

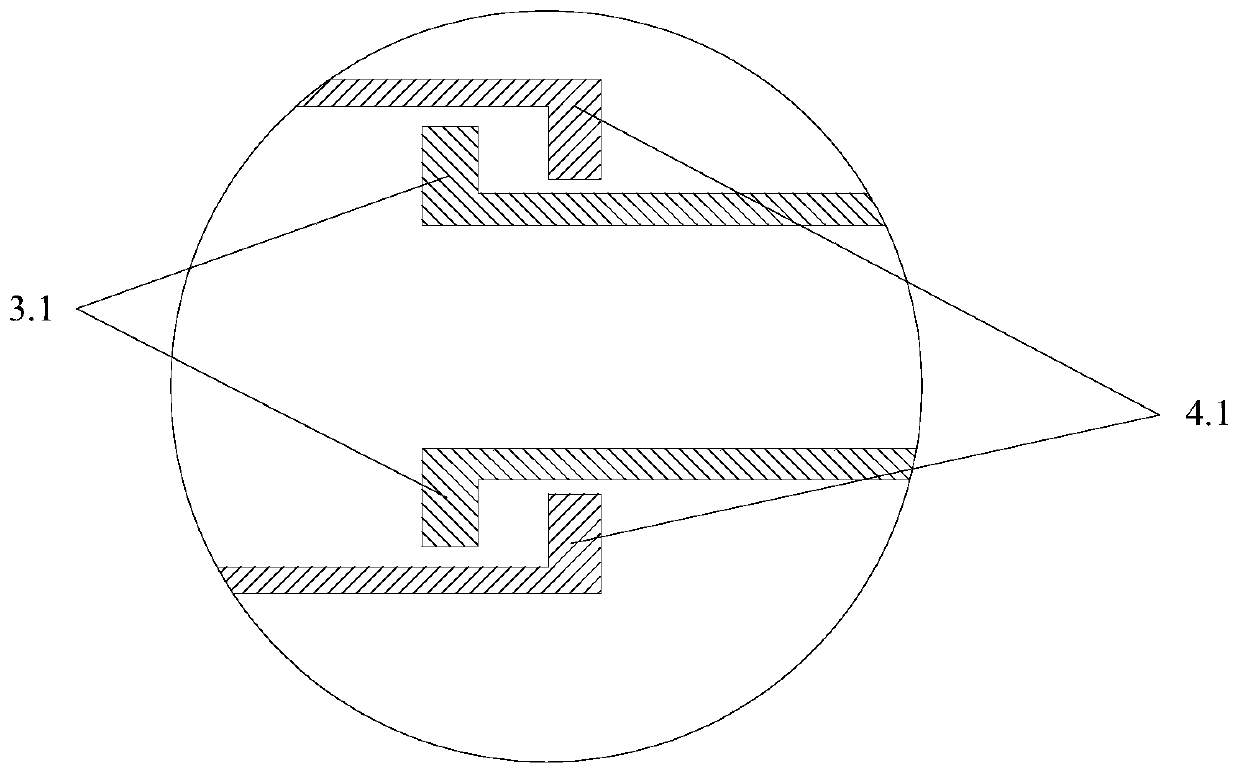

[0031] Below in conjunction with accompanying drawing, the present invention is further described:

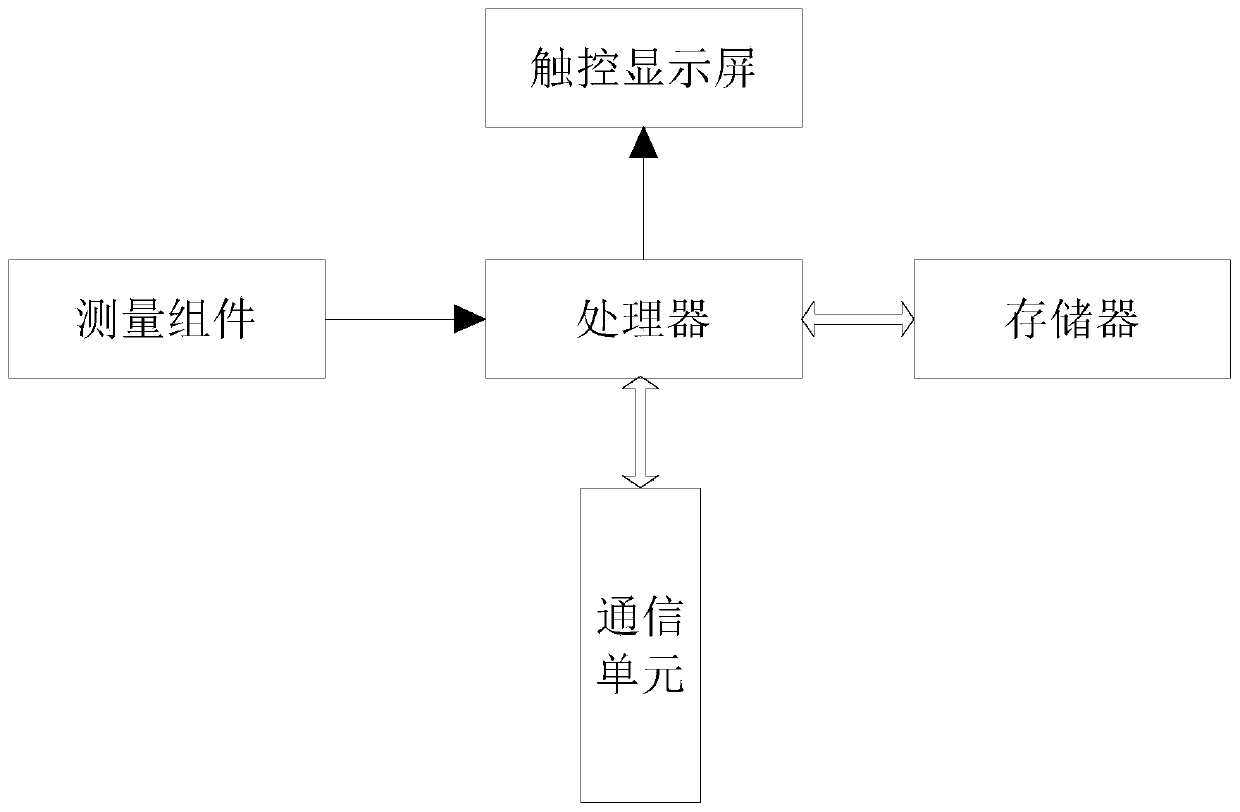

[0032] The invention provides a displacement monitoring device based on optical fiber bending loss, which is characterized in that: it includes: a displacement acquisition conversion component, a measurement component connected to the output end of the displacement acquisition conversion component, and a measurement component to be measured is calculated according to the measurement data of the measurement component. The data processor of the target displacement, the processor adopts existing programmable chips, such as 51 series chips, those skilled in the art can choose and buy according to actual needs, and use the existing technology to complete the chip according to the instructions of the chip The writing of the main control program will not be repeated here.

[0033] The displacement monitoring device is used to measure the displacement caused by cracks and sliding cause...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com