Synchronous driving mechanism of bottom frame of movable rack

A technology of synchronous drive and drive mechanism, applied in mechanical equipment, transmission devices, cabinets for storing books, etc., can solve the problems of heavy weight of the overall hand-crank mechanism, complicated manufacturing process, inconvenient maintenance and repair, etc., and achieve the goal of transmission structure and transmission mode Reasonable, large range of transmission ratio, convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

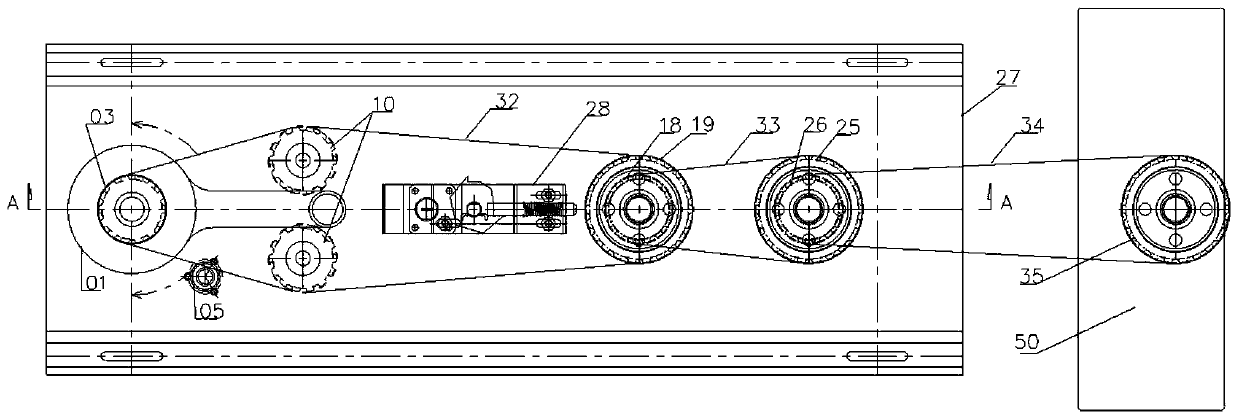

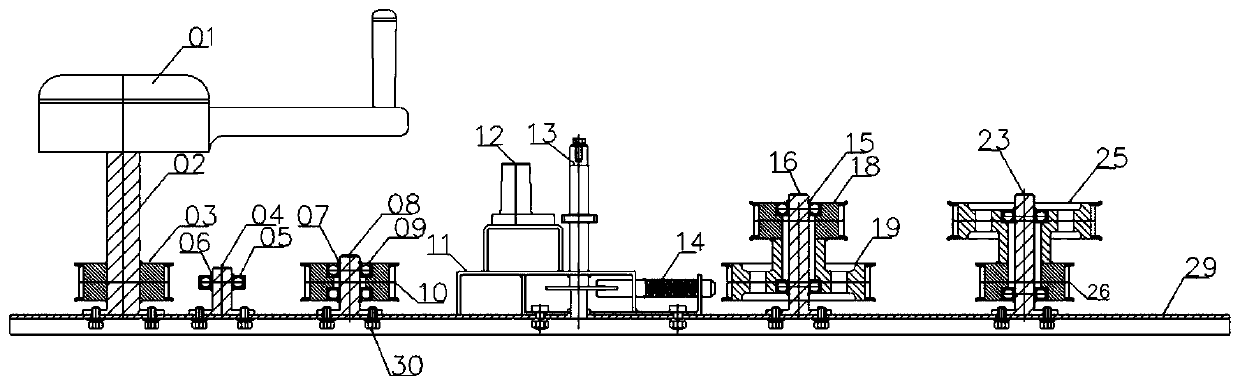

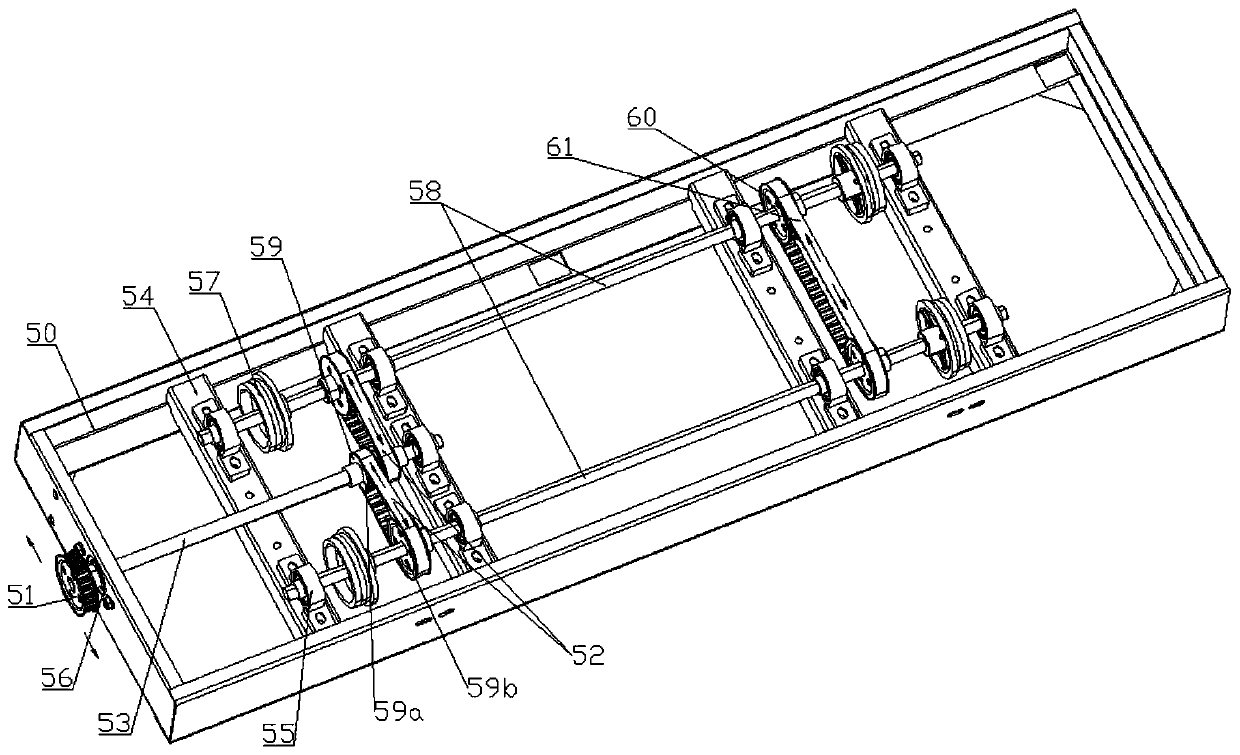

[0009] In order to further understand the technical solution of the present invention, the present invention will be further described by the following embodiments in conjunction with the accompanying drawings. Such as Figure 1-3 The present invention relates to the synchronous transmission chassis of the synchronous drive mechanism of the underframe of the dense rack, the synchronous transmission hand crank mechanism and the like. The synchronous drive manual mechanism includes the main synchronous pulley 03, the transition synchronous pulley, the output synchronous pulley, and the balance tension synchronous pulley, which are arranged on the integrated frame 27 through the corresponding T-axis and the mutual transmission of the corresponding synchronous belt. And locking brake device 28 etc.

[0010] Its transition synchronous pulley includes a transition large synchronous pulley 19 and a transition small synchronous pulley 18 which are arranged on the corresponding transi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com