Control system and method for uniformity of nonwoven fabric

A technology of uniform control and non-woven fabrics, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problem of uneven horizontal arrangement of slit-drawn fibers, prevent fiber disorder, increase air intake area, and increase air intake. The effect of large passing cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

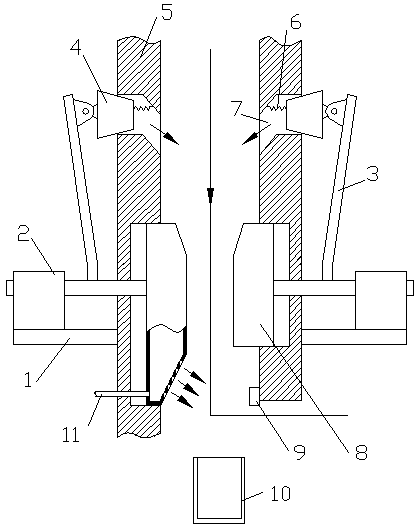

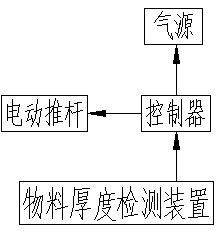

[0024] Such as figure 1 A uniform control system for non-woven fabrics is shown, including a suction air unit 10, a channel with an air supply hole 7 on the side wall, and a cavity with an air inlet pipe in a slider on one side, and the slider has a direction to change the direction of the material. The pressure stabilizing device of the air outlet on the inclined plane, the width of the air supply air channel is 5~50mm, after the fibers sprayed from the spinning box are cooled by the cold air, the fibers are blown under the action of the drafter and the suction air unit 10 Moving along the channel, the drafter can adopt the existing technology, and its detailed structure will not be repeated here.

[0025] There are several groups of sliders slidably connected to the side wall 5 of the channel. Each group of sliders inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com