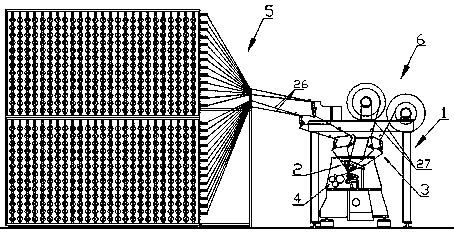

Tricot jacquard warp knitting machine with jacquard mechanism and method of adjusting jacquard stitch length

A technology of warp knitting machines and jacquard needles, which is applied in the field of warp knitting machines, can solve the problems of difficulty in forming various jacquard effects, single and simple jacquard effects, and the horizontal movement of guide needles cannot be too large, so as to improve the flexibility of jacquard , easy to complicate, and the effect of lengthening the stitch distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

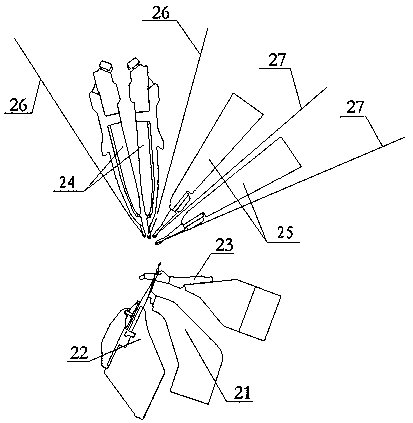

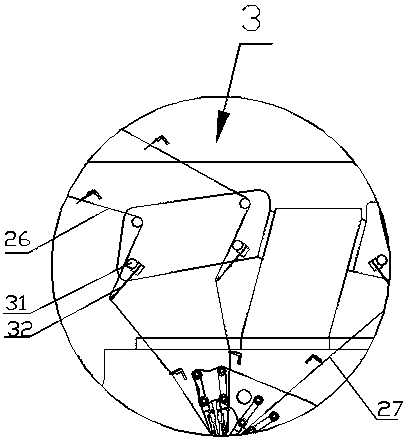

Method used

Image

Examples

example 1

[0043] Example 1: see Figure 5 , when the traverse chain goes from 5 to 4, the jacquard guide needle pushes one stitch to the right before the groove needle, so that the yarn is not hooked into the needle hook, the yarn floats out, and no loop is formed. When the traversing chain block goes from 4 to 0, at the needle back of the groove needle, the jacquard guide needle recovers one stitch to the left.

[0044] In the next row, when the traverse chain block goes from 0 to 1 into a coil.

[0045] At this time, the jacquard pitch is 1 stitch.

[0046] Further, when the jacquard guide needle moves leftward, the jacquard guide needle pushes one stitch to the right in front of the groove needle, so that the yarn is not hooked into the needle hook, and the yarn floats out without forming a loop ; And in the next row, when the jacquard guide needle traverses to the left before the end, the jacquard guide needle recovers one stitch to the left, so that the yarn is not hooked into the ...

example 2

[0047] Example 2: see Figure 6 , when the traverse chain goes from 5 to 4, the jacquard guide needle pushes one stitch to the right before the groove needle, so that the yarn is not hooked into the needle hook, the yarn floats out, and no loop is formed.

[0048] In the next row, when the traversing chain block goes from 1 to 0, the jacquard guide needle recovers one needle to the left, so that the yarn is not hooked into the needle hook, the yarn floats out, and no loop is formed.

[0049] At this time, the jacquard pitch is 0 stitches.

example 3

[0050] Example 3: see Figure 7 , when the traversing chain moves from 1 to 5, the Jacquard yarn guide needle pushes one stitch on the back of the groove needle to the right;

[0051] In the next row, when the traversing chain block goes from 4 to 0, at the needle back of the groove needle, the jacquard guide needle recovers one needle to the left;

[0052] At this time, the jacquard pitch is 6 stitches, which is one stitch longer than the original jacquard pitch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com