Container loading and unloading device for port logistics

A loading and unloading device, container technology, applied in the direction of loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of inconvenient storage and achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

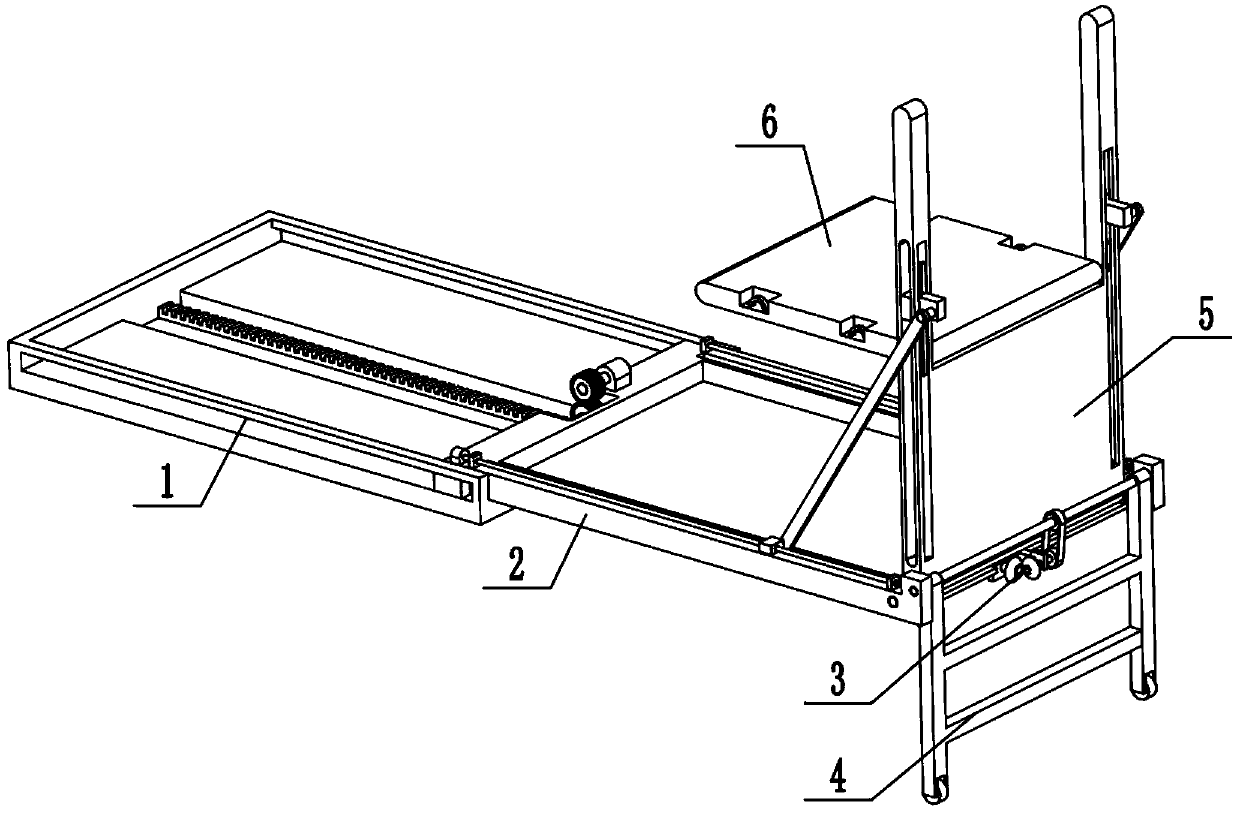

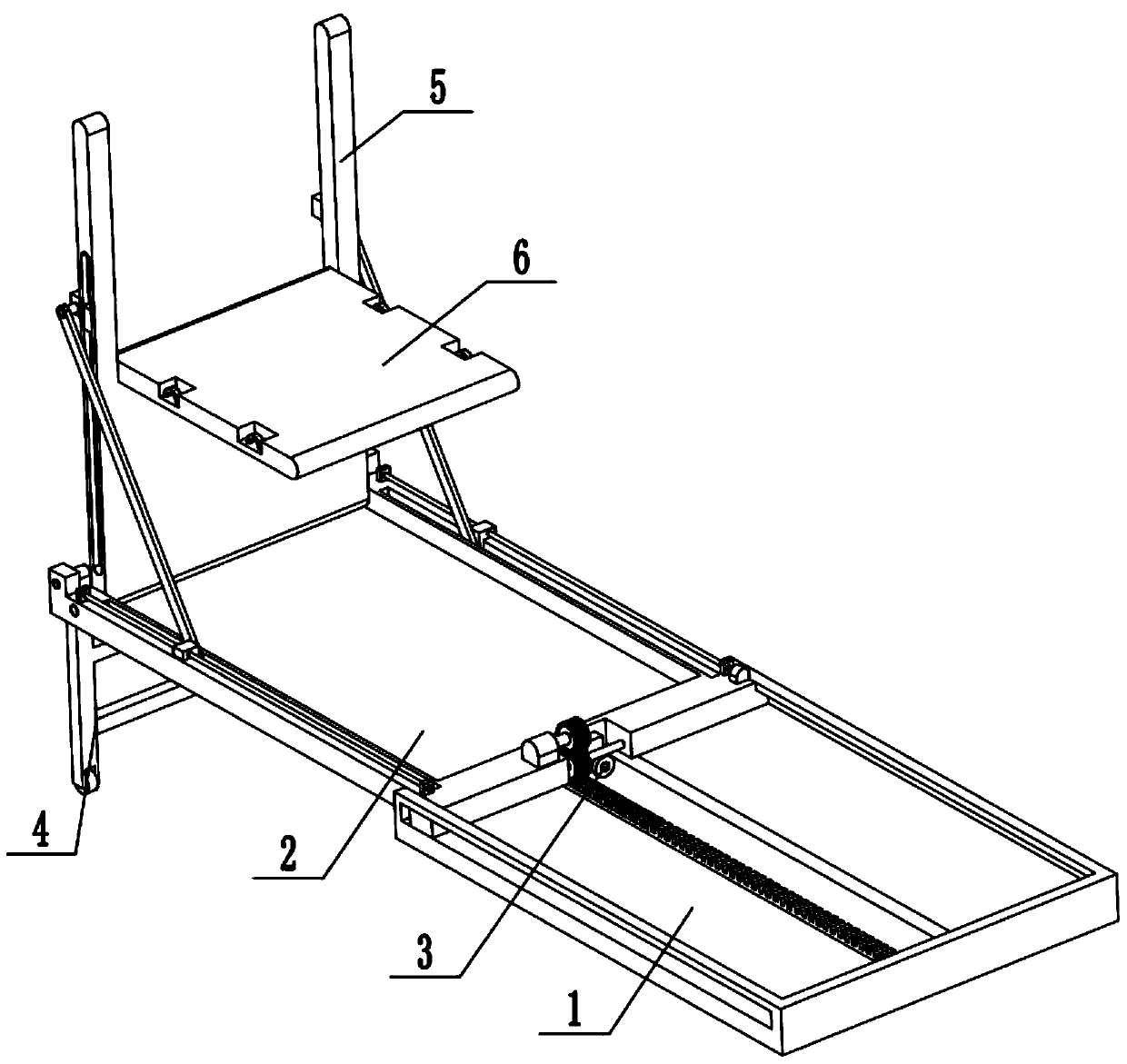

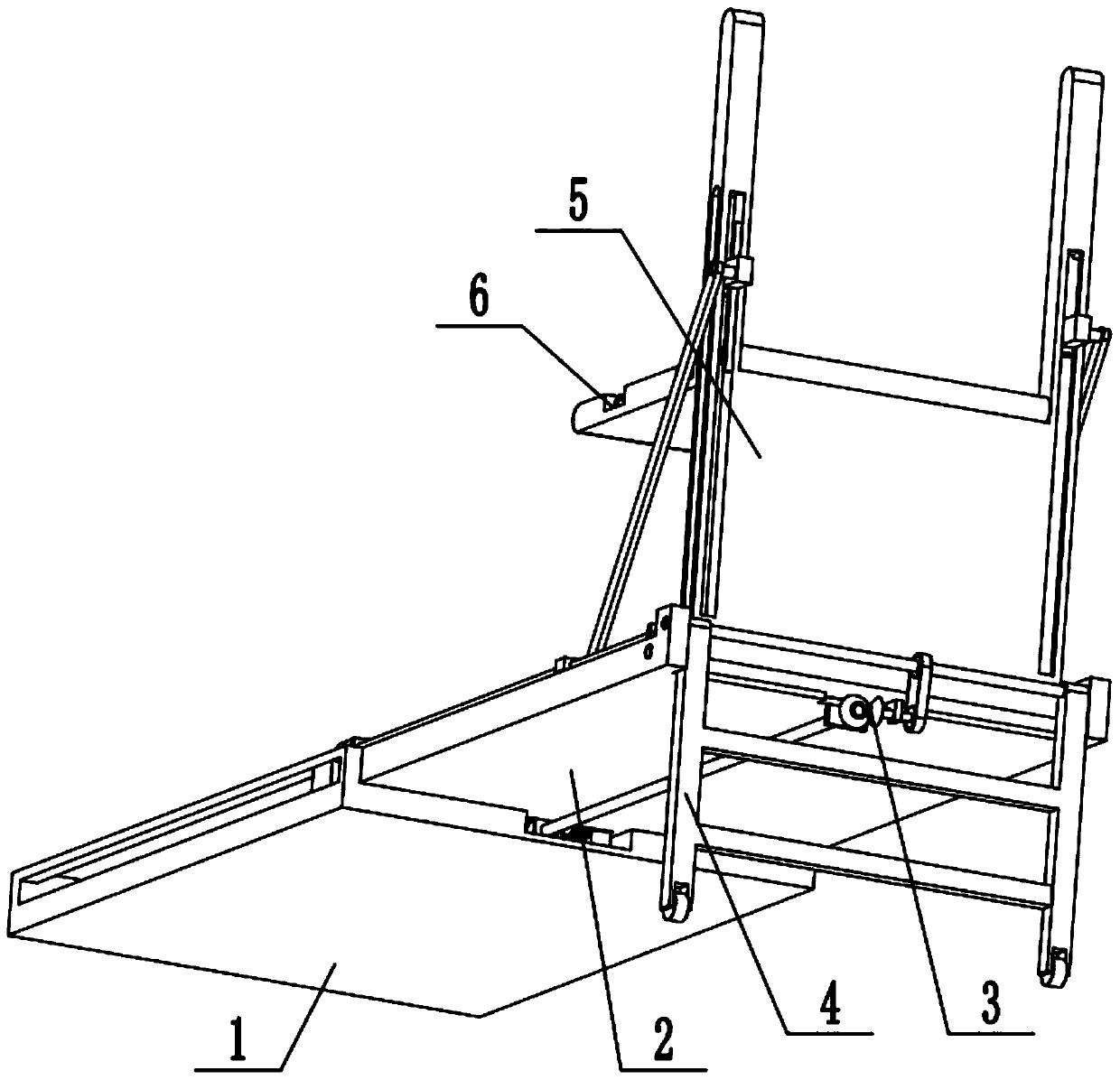

[0032] Combine below Figure 1-15Describe this embodiment, a port logistics container loading and unloading device, including a fixed base 1, a sliding base assembly 2, a power transmission wheel set 3, a support wheel assembly 4, an overturning plate frame mechanism 5 and an overturning storage plate 6, the sliding base The assembly 2 is arranged on the fixed base 1, the sliding base assembly 2 is connected with the fixed base 1 in transmission, the power transmission wheel set 3 is arranged at the lower end of the sliding base assembly 2, the power transmission wheel set 3 is in transmission connection with the sliding base assembly 2, and the supporting wheel assembly 4 is arranged on the right end of the sliding base assembly 2, the supporting wheel assembly 4 is in transmission connection with the power transmission wheel set 3, the flipping frame mechanism 5 is arranged on the sliding base assembly 2, the flipping frame mechanism 5 is in transmission connection with the s...

specific Embodiment approach 2

[0034] Combine below Figure 1-15 To illustrate this embodiment, the fixed base 1 is provided with a U-shaped frame 1-1, a baffle plate 1-2, a rectangular groove 1-3 and a rack I1-4, and two U-shaped racks are symmetrically fixedly connected on the fixed base 1. Frame 1-1, the left end of the fixed base 1 is fixedly connected to the baffle plate 1-2, the middle part of the fixed base 1 is provided with a rectangular slot 1-3, the rack I 1-4 is fixedly connected to the bottom surface of the rectangular slot 1-3, and the sliding base Component 2 is in transmission connection with rack I1-4.

specific Embodiment approach 3

[0036] Combine below Figure 1-15 To illustrate this embodiment, the sliding base assembly 2 includes a sliding plate 2-1, a bump 2-2, a gear placement groove 2-3, a motor I 2-4, a driving gear 2-5, a driven gear 2-6, Worm screw 2-7, receiving groove 2-8, horizontal slide groove 2-9, motor II 2-10, lead screw 2-11, lead screw seat 2-12, guide rod 2-13 and guide rod frame 2-14; slide The left side of the plate 2-1 is symmetrically fixedly connected to two protrusions 2-2, the sliding plate 2-1 is slidingly fitted and connected to the upper end surface of the fixed base 1, and the two protrusions 2-2 are respectively slidingly fitted and connected to two U-shaped Inside the frame 1-1, the left end of the sliding plate 2-1 is provided with a gear placement groove 2-3, the motor I2-4 is fixedly connected to the sliding plate 2-1 through the motor frame, and the output shaft of the motor I2-4 is fixedly connected to the driving gear 2-5, the driving gear 2-5 is meshed with the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com