Flame-retardant polyester-spandex composite fabric

A composite fabric, flame retardant technology, applied in the field of textile fabrics, can solve the problems of unsatisfactory flame retardant effect of clothing fabrics, clothing can not be worn for a long time, bacteria breeding, etc. dry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

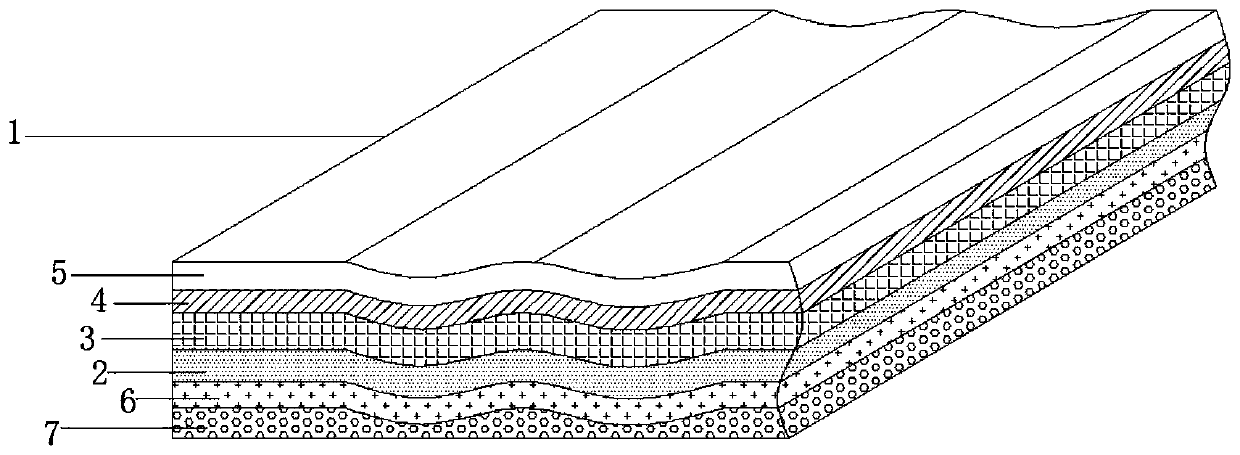

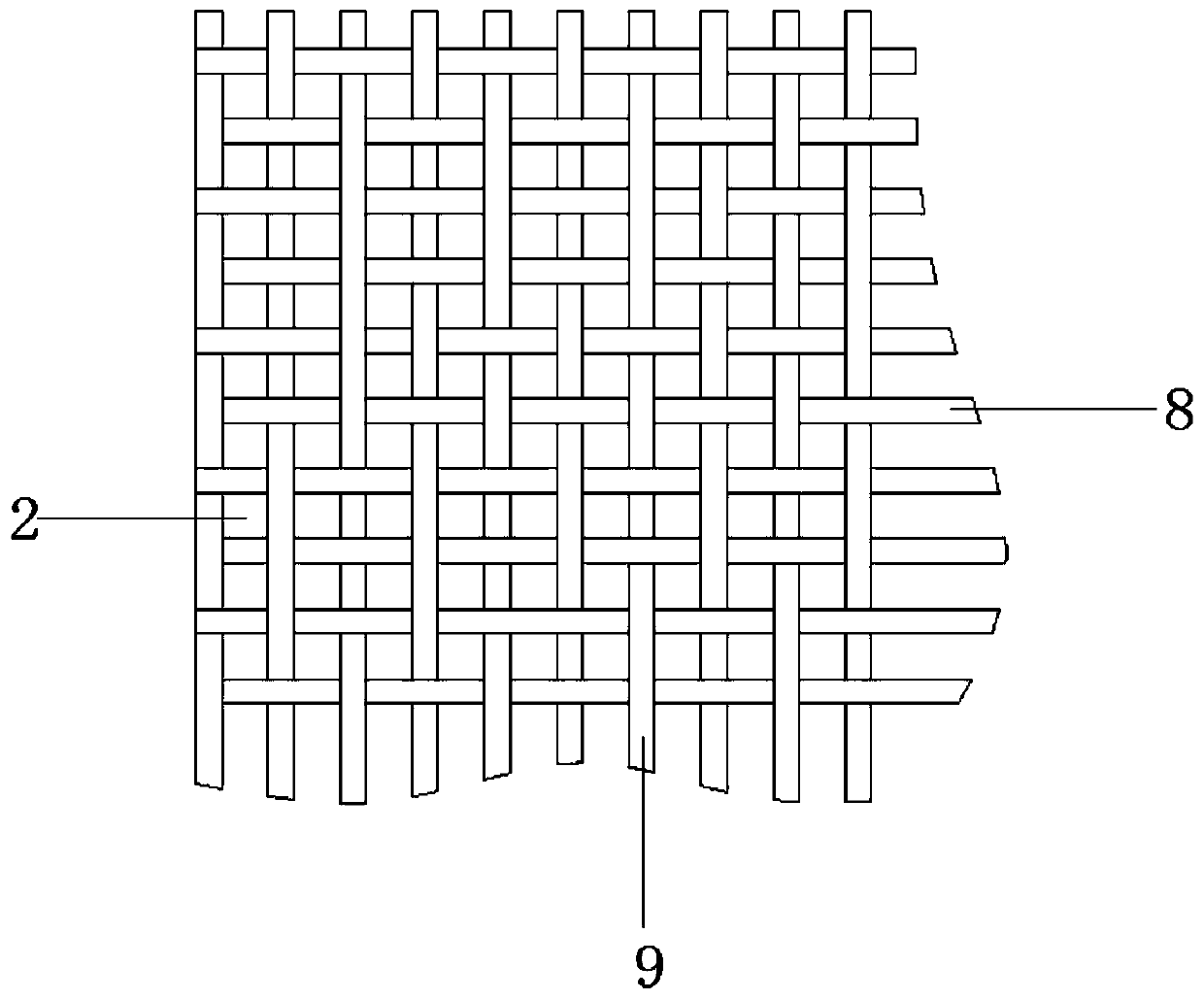

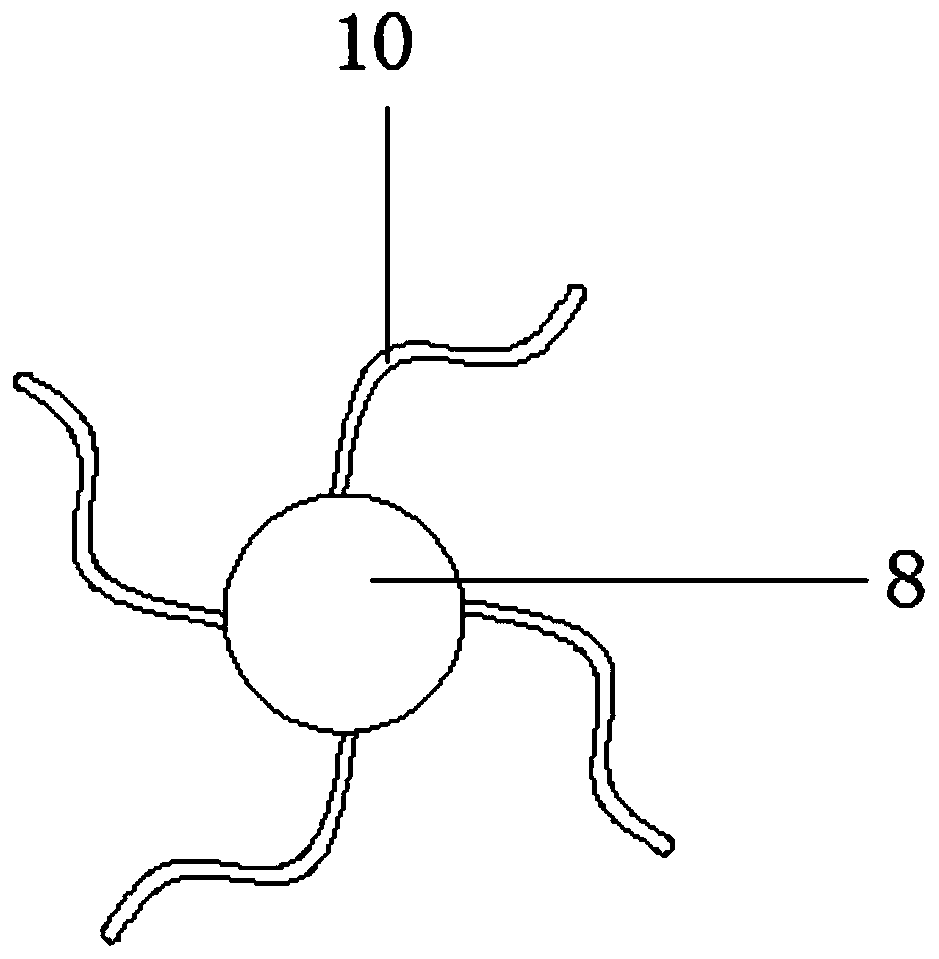

[0019] like Figure 1-4 As shown, a flame-retardant polyester-spandex composite fabric includes a fabric body 1, and the fabric body 1 includes a base cloth layer 2, an antibacterial layer 3, a flame-retardant layer 4, a waterproof layer 5, a bamboo charcoal fiber deodorant layer 6, Cotton fiber layer 7, the antibacterial layer 3 is arranged on the top of the base cloth layer 2, by setting the antibacterial layer 3 and nano antibacterial silver wire 10, the nano silver antibacterial particles can effectively inhibit and kill bacteria, the flame retardant layer 4 is set On the top of the antibacterial layer 3, the waterproof layer 5 is arranged on the top of the flam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com