Automobile stabilization rod gum cover vulcanizing assembly fixture and gum cover assembly vulcanizing method

A technology for assembling fixtures and stabilizing bars, which is applied to home appliances, other home appliances, and household components, can solve problems such as waste of resources and increase production costs, and achieve cost savings for complex molds, increase production efficiency, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention and are not intended to to limit the present invention.

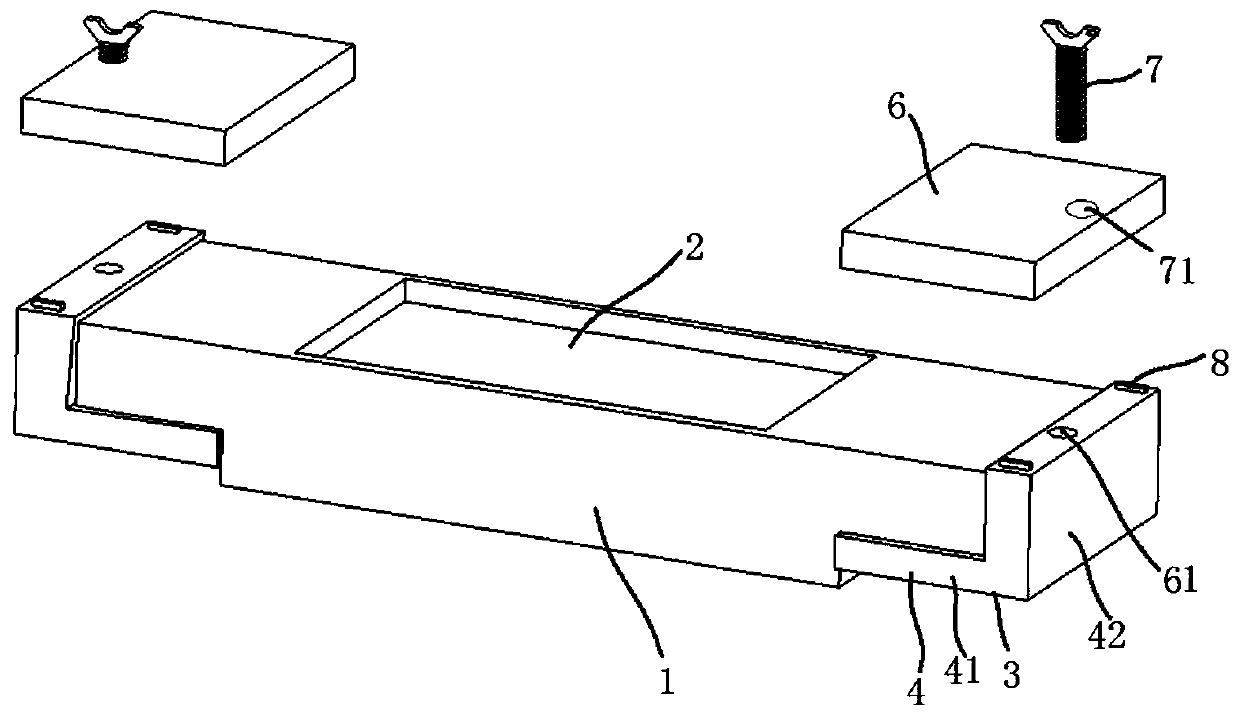

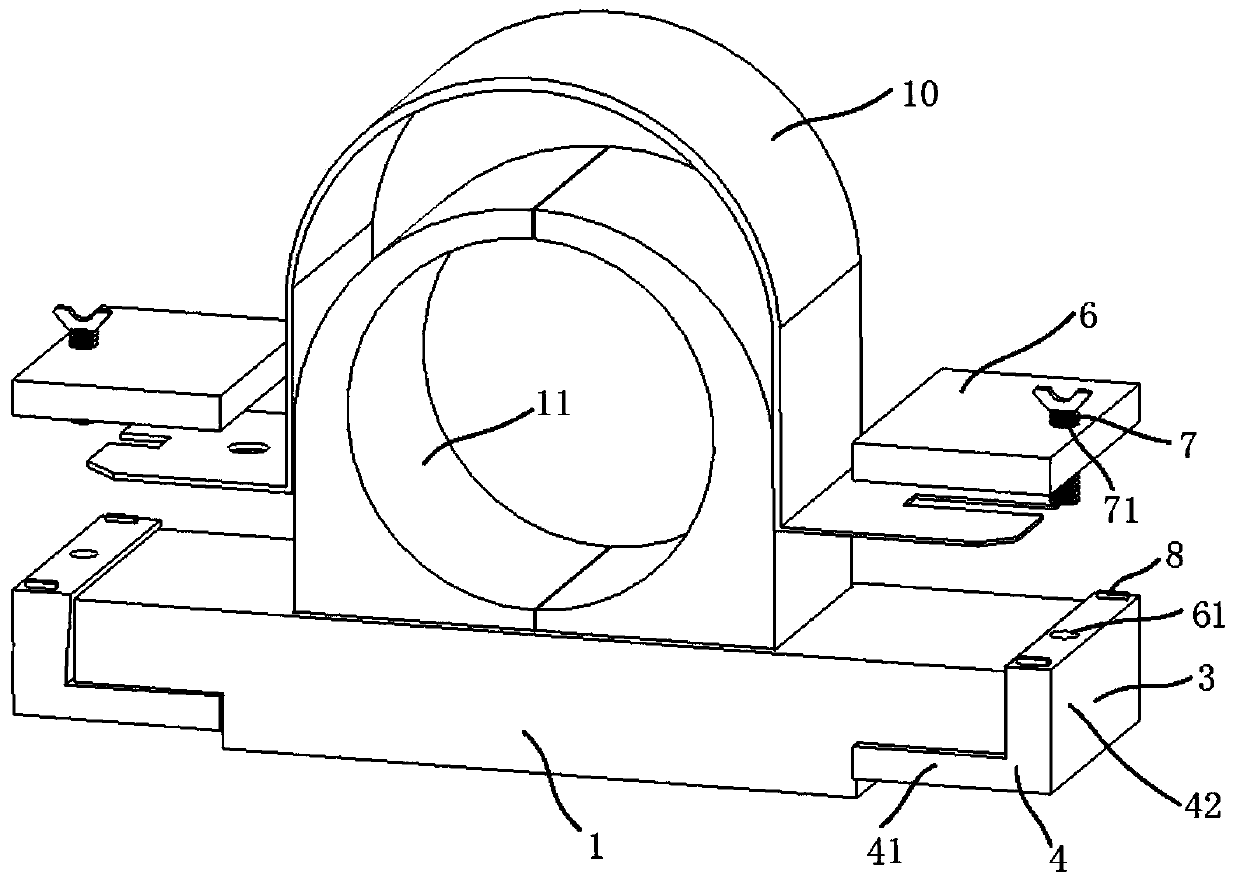

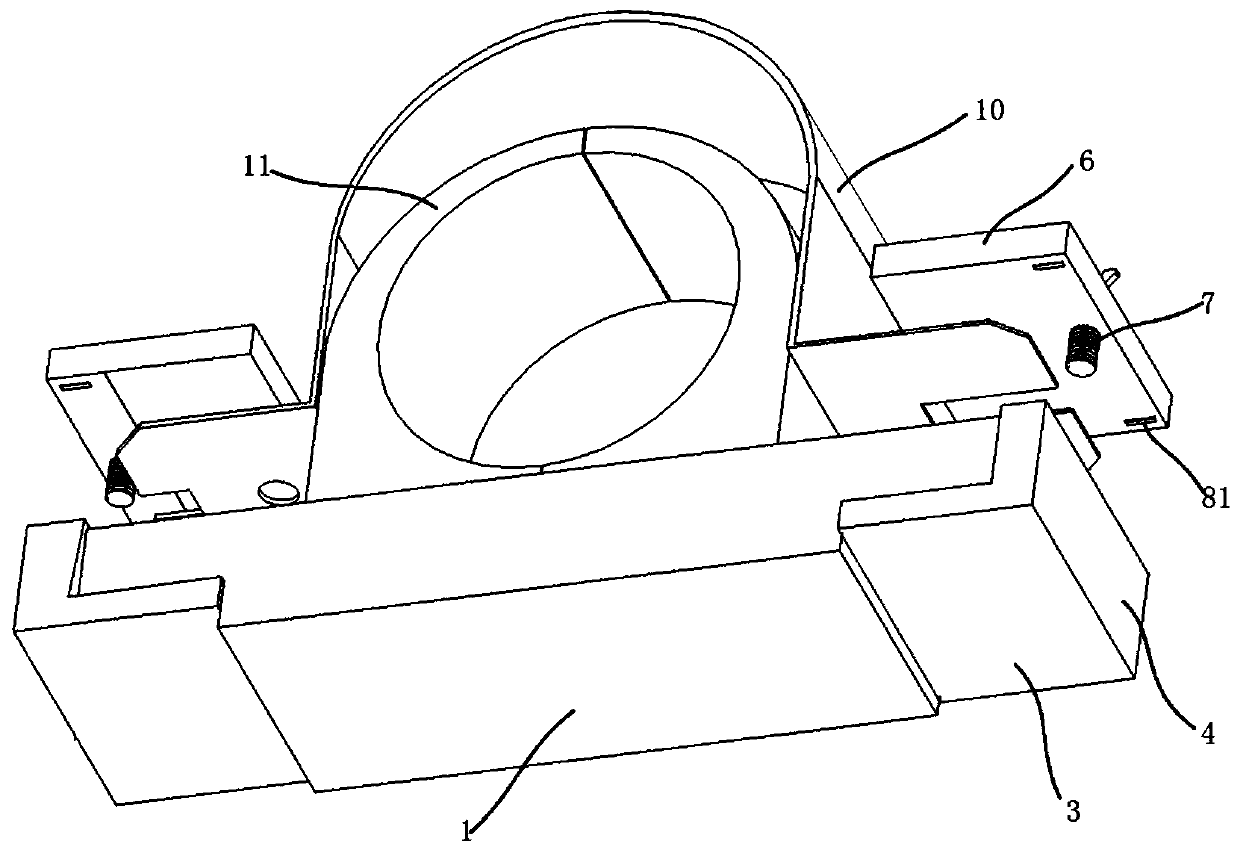

[0038] refer to Figure 1-7 As shown, the automobile stabilizer bar rubber sleeve vulcanization assembly fixture includes a flat base 1 and a concave clip 3, both ends of the flat base 1 are embedded with concave clips 3, and the upper table of the flat base 1 has a rectangular Limiting groove 2, the rectangular limiting groove 2 is used to embed the bottom end of the U-shaped rubber sleeve 11; the concave clamp 3 is an L-shaped lower clamping plate 4 and an upper clamping plate 6 composed of a horizontal plate 41 and a vertical plate 42 Matched to form a U shape;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com