Nut preparation equipment

A nut and equipment technology, applied in the field of nut preparation equipment, can solve problems such as inability to give early warning, undetectable, inconsistent thread direction, etc., and achieve the effect of achieving quality consistency, ensuring stability, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

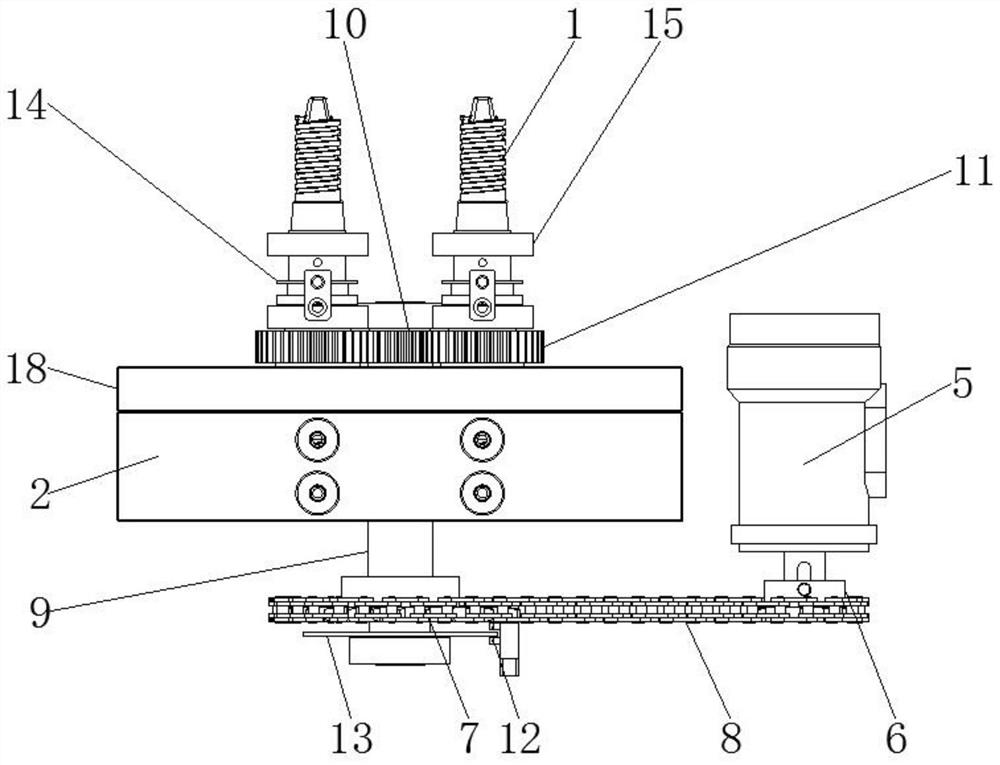

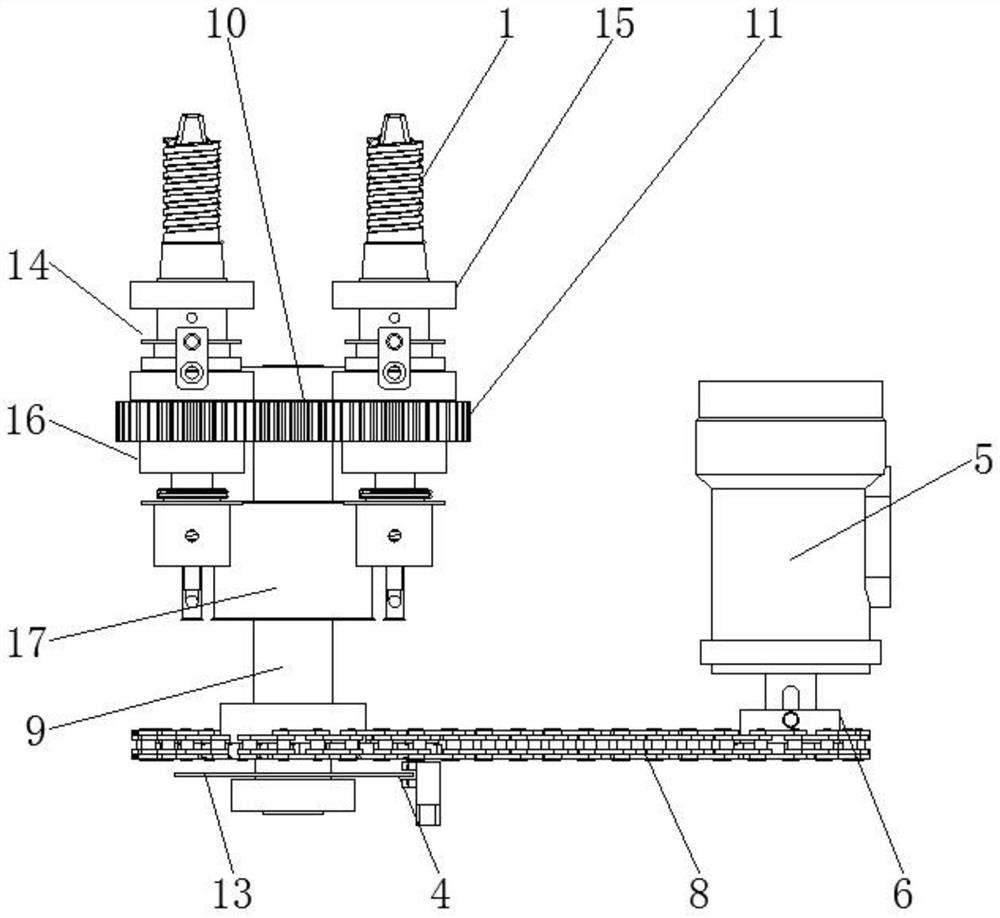

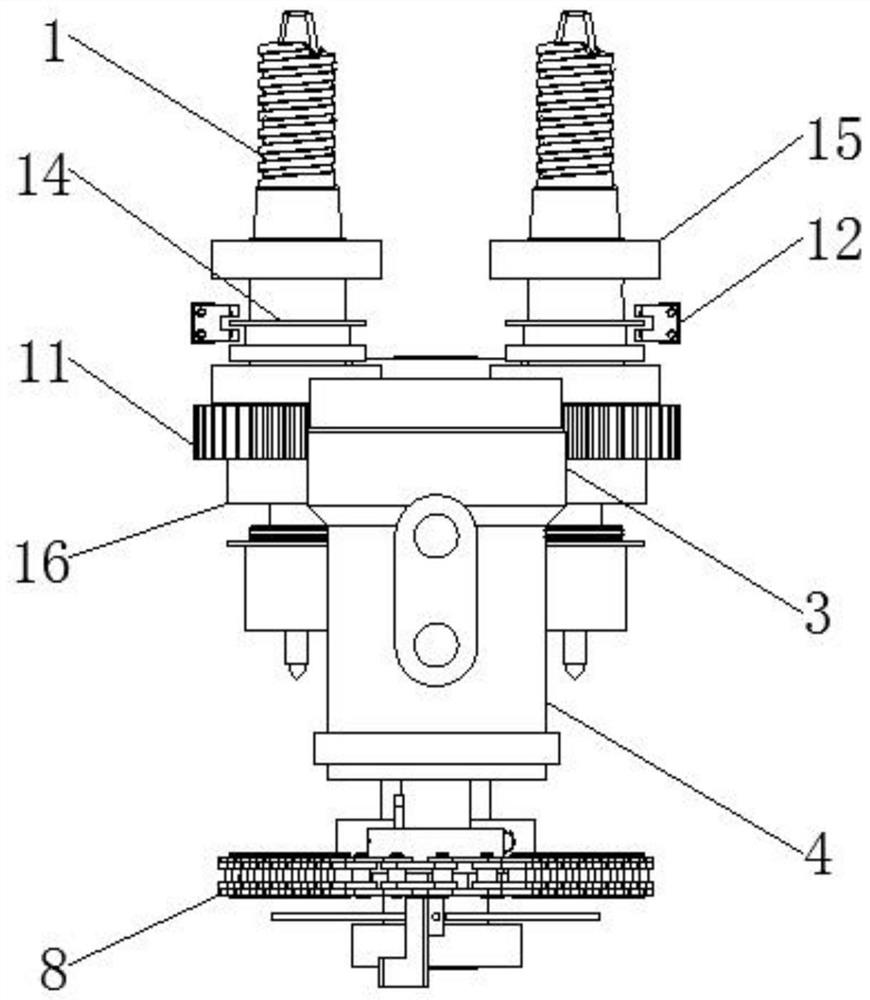

[0021] The specific embodiment: the hydraulic motor 5 output torque drives the driving sprocket 6 to rotate, and the driven sprocket 7 is rotated through the action of the chain 8, and the driving gear 10 is driven to rotate through the action of the transmission shaft 9. Because the driving gear 10 and the driven gear 11 Mesh, and then drive the four driven gears 11 to rotate, and drive the four threaded shafts 1 to rotate synchronously, thereby realizing demoulding, and the four sets of nuts are processed and produced at the same time, which not only ensures the quality consistency of the product, but also greatly improves the output.

[0022] Induction detection assembly 4 comprises inductor 12, first induction ring 13 and second induction ring 14, and described inductor 12 is provided with five, and five inductors 12 are respectively positioned at driven sprocket 7 bottom side and four On one side of the threaded shaft 1, the first induction ring 13 is fixed at the shaft ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com