Feed processing device

A feed processing and equipment technology, applied in the field of feed processing equipment, can solve the problems of single function, inconvenient multi-type, small batch feed processing, unable to meet production needs, etc., to achieve the effect of saving water resources, saving space and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

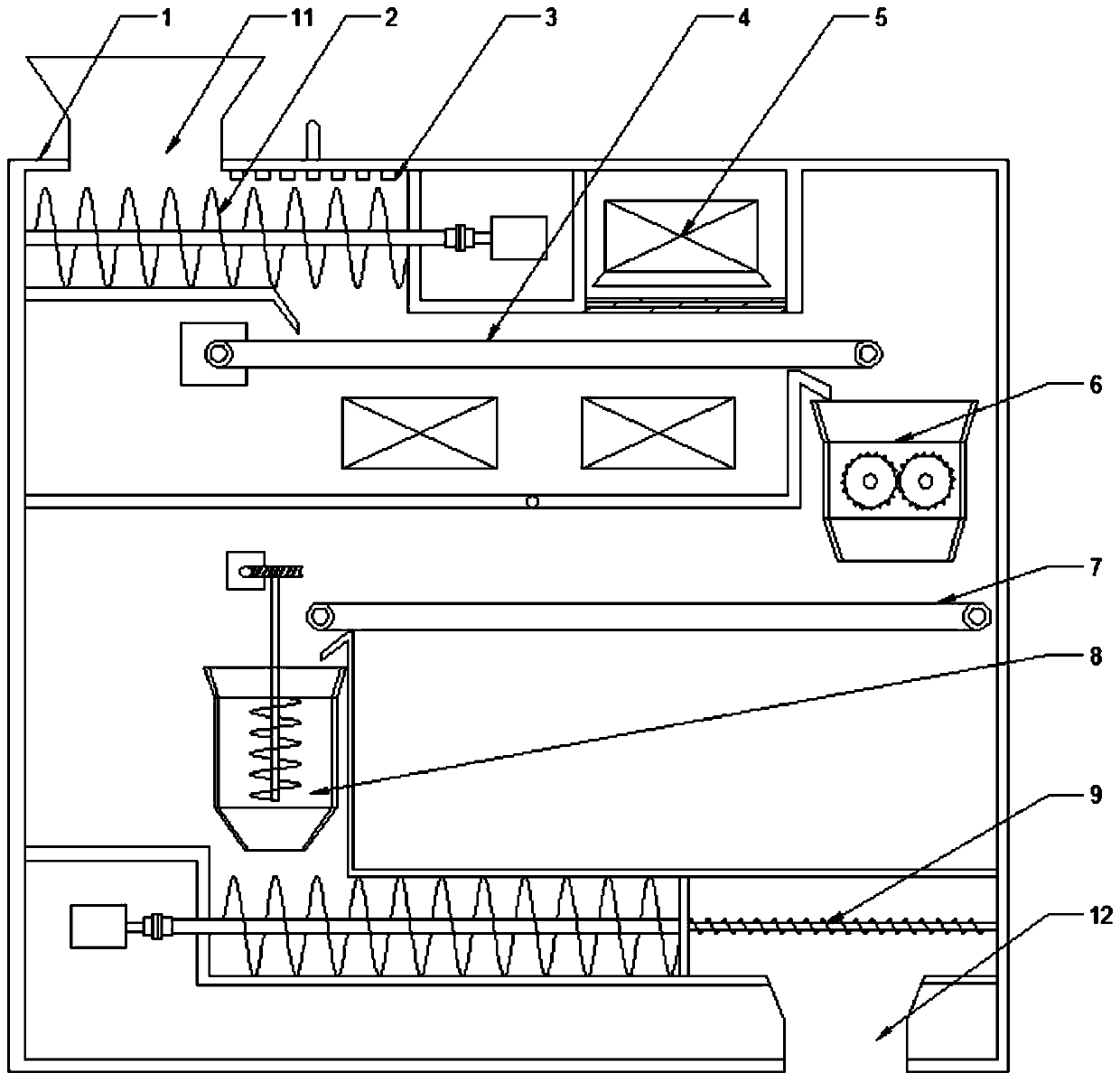

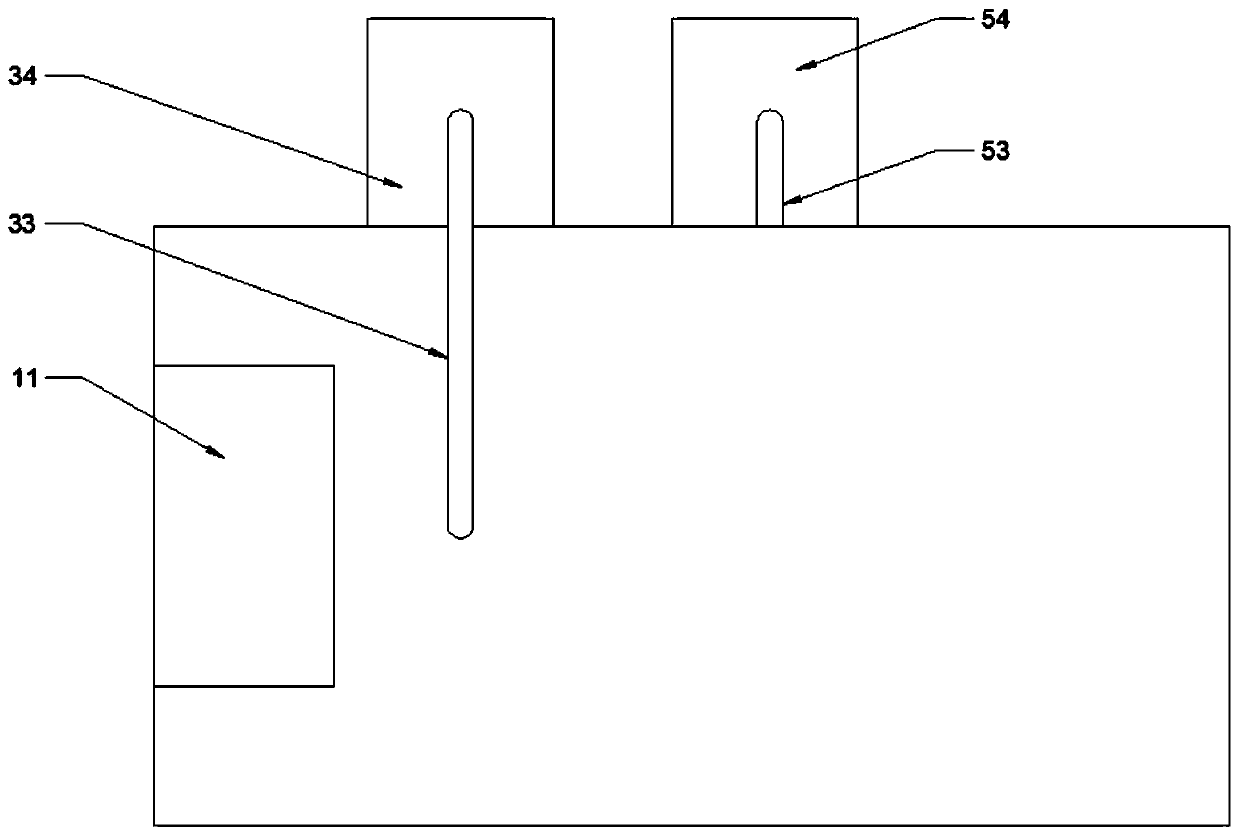

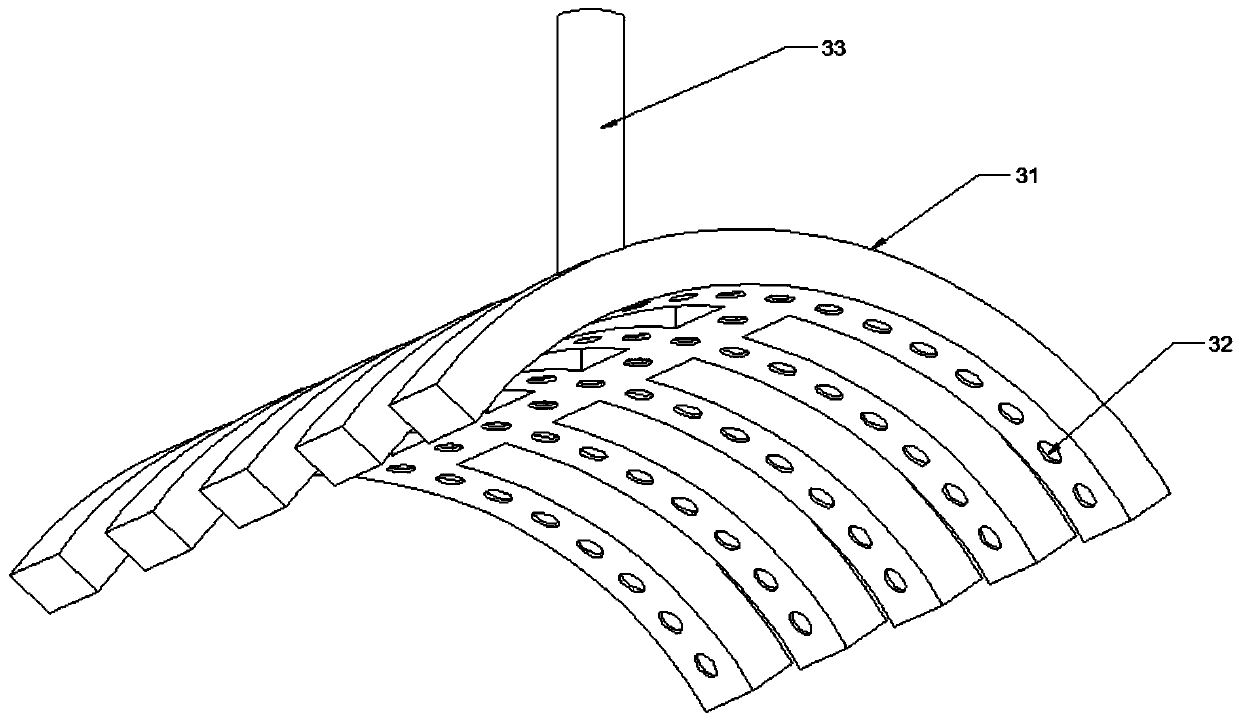

[0029] see Figure 1~3 , in an embodiment of the present invention, a feed processing equipment includes a box body 1 and a feeding mechanism arranged inside the box body 1, a side of the top of the box body 1 is provided with a feed port 11, and the box body 1 A discharge port 12 is provided on the side of the bottom away from the feed port 11 , and the conveying mechanism includes a first conveying mechanism 2 , a second conveying mechanism 4 , a third conveying mechanism 7 and a fourth conveying mechanism 9 .

[0030] The first conveying mechanism 2 is fixedly installed below the feeding port 11, and the first conveying mechanism 2 includes a first motor 21, a first rotating shaft 22 and a first screw blade 23, and the first rotating shaft 22 passes through The elastic coupling is connected with the first motor 21, the first helical blade 23 is fixedly mounted on the first rotating shaft 22, and the first rotating shaft 22 drives the first helical fan blade 23 to rotate, th...

Embodiment 2

[0039] see Figure 2-4 , in the embodiment of the present invention, a feed processing equipment, on the basis of embodiment 1, a load cell 74 is added at the bottom of the second conveyor belt 73, and a variety of materials are put into the box body 1 from the feed port 11, and sequentially Cleaning, drying, crushing, stirring and extruding into cakes, and then discharged from the discharge port 12, but the weight of the materials after cleaning, drying and crushing changes, it is difficult to control their quantitative mixing and stirring, resulting in various When the various materials are mixed and stirred, the proportion is uncertain. A load cell 74 is installed at the bottom of the second conveyor belt 73, which can sense the weight of each material before it enters the mixing container and give feedback to the user. When the proportion of various materials is serious When it is out of balance, it can be controlled in time and monitored in real time, which improves work ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com