Processing method for improving water holding capacity of beef

A processing method and water-holding technology, which is applied in the field of processing to improve the water-holding capacity of beef, can solve the problems of poor sensory eating quality and poor water-holding capacity of beef, and achieve the effect of increasing sensory eating quality and improving water-holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

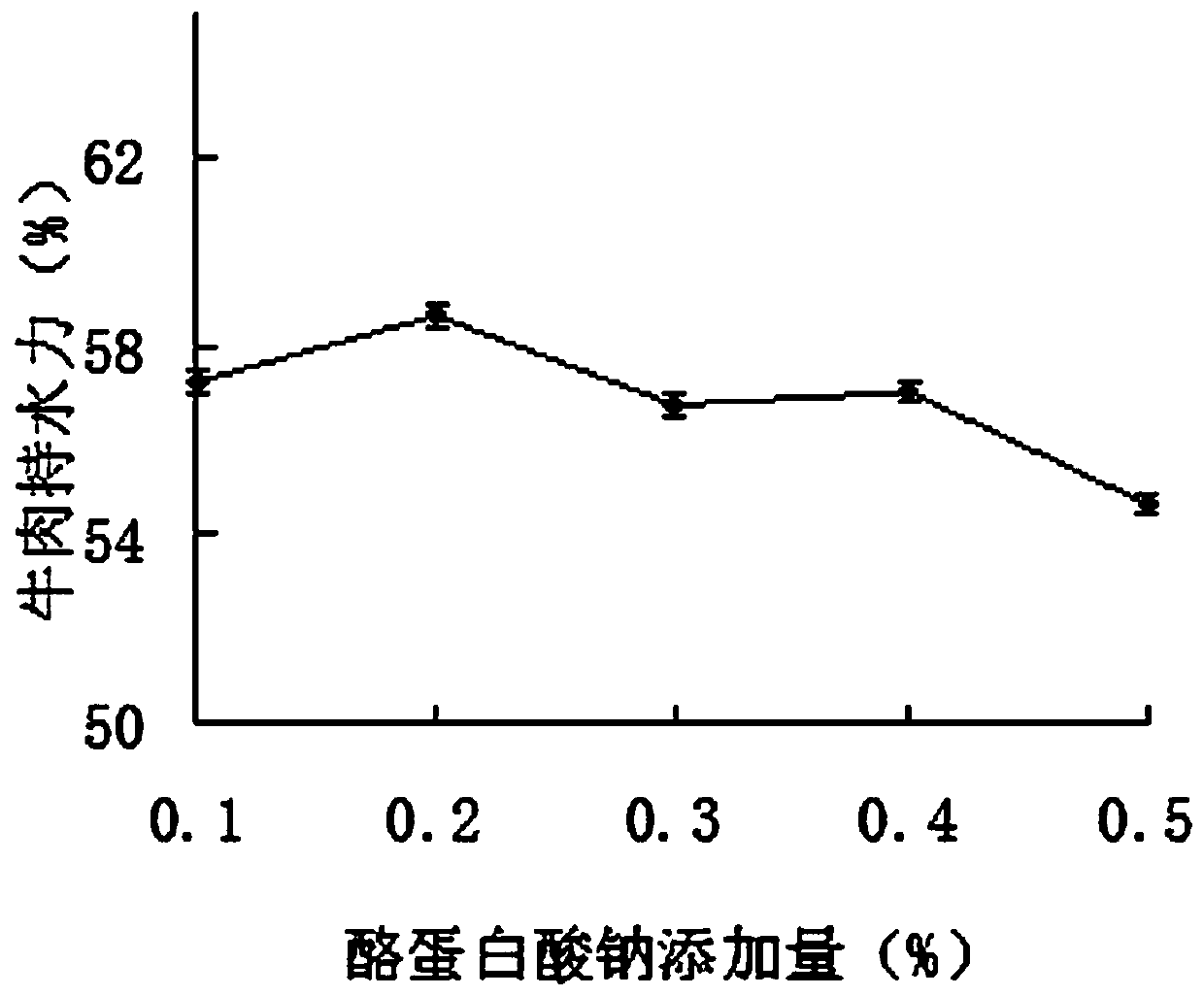

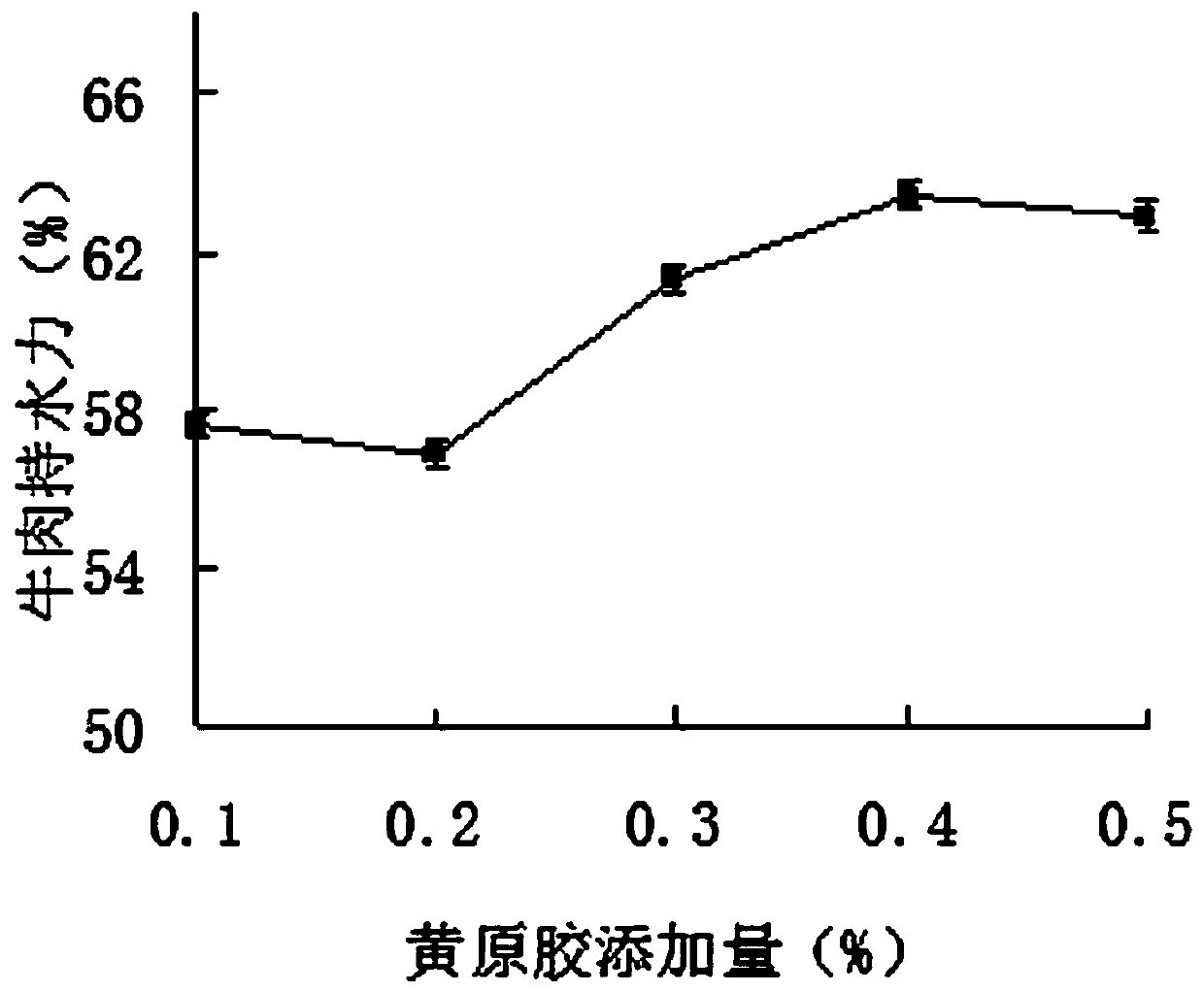

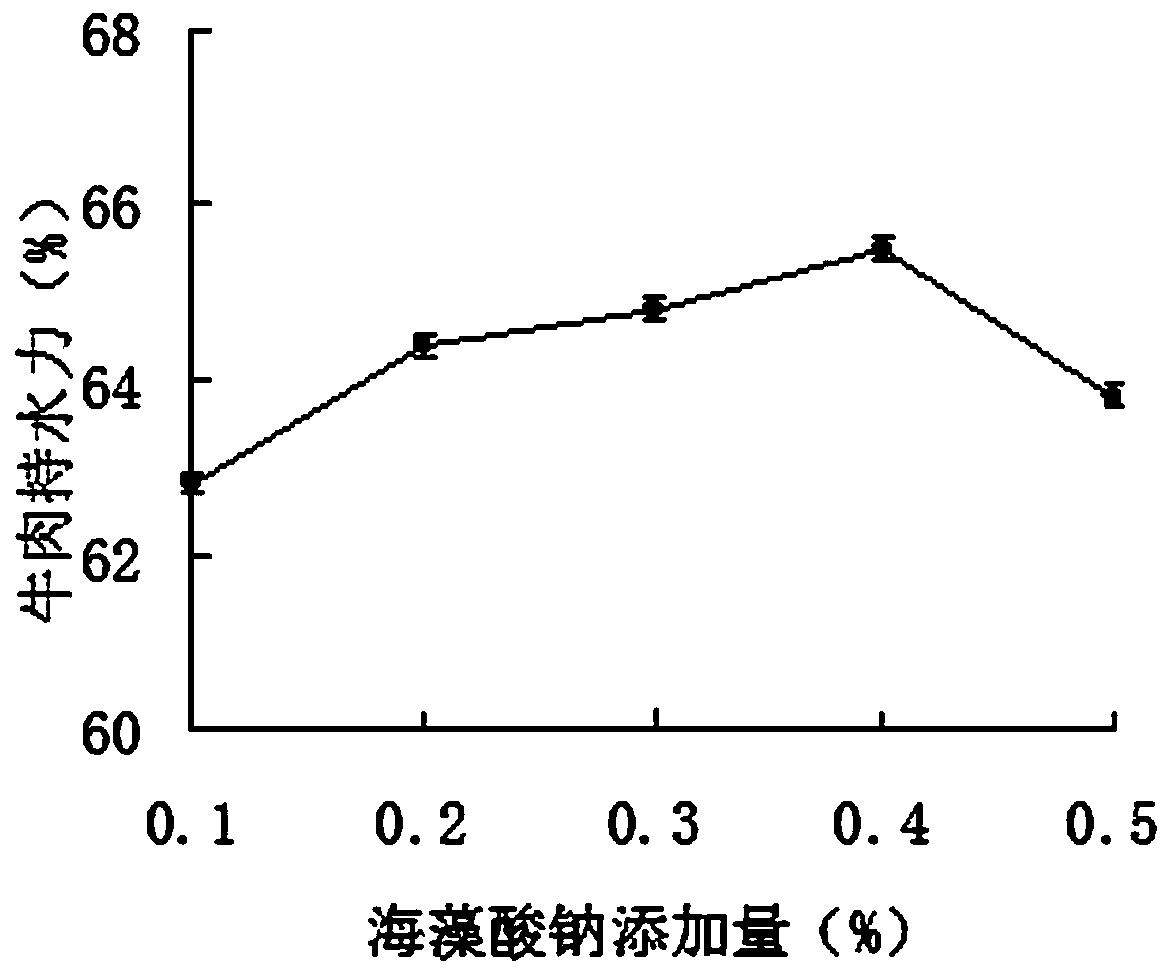

Embodiment 1

[0025] Sodium caseinate (0.1%—0.5%), xanthan gum (0.1%—0.5%), sodium alginate (0.1%—0.5%), sodium tripolyphosphate (0.1%—0.5%); Sodium, xanthan gum, sodium alginate and sodium tripolyphosphate are divided into 5 groups according to the proportion, and an appropriate amount of water is added to dissolve each group of sodium caseinate, xanthan gum, sodium alginate and sodium tripolyphosphate solution; take the beef out of the freezer of the refrigerator and thaw it. After the beef is completely thawed, wash it with clean water, and then evenly cut it into several beef pieces with a mass of 10g; weigh 10g of beef, slice it and put it in a blast drying oven at 110°C Dry in medium for 4 hours, take it out and weigh it, put it in the drying oven again for 1 hour and weigh it until the constant weight observation error is 0.002g, then calculate the moisture content; put several equally cut meat samples into the prepared water-retaining agent solution In the process, after the beef fu...

Embodiment 2

[0027] The concentrations of sodium caseinate, xanthan gum, sodium alginate, and sodium tripolyphosphate were all configured to be 0.1%, and other conditions were the same as in Example 1.

Embodiment 3

[0029] The concentrations of sodium caseinate, xanthan gum, sodium alginate, and sodium tripolyphosphate were all configured to be 0.2%, and other conditions were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com