Disdisassembly-prevention union nut assembly, pipeline system and domestic appliance

A union nut and anti-disassembly technology, which is applied in the direction of pipe/pipe joint/pipe fitting, passing element, sealing surface connection, etc., can solve the problems of low installation efficiency, high manufacturing cost, and large number of parts, so as to improve assembly efficiency and assembly The effect of fewer processes and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that, in the case of no conflict, the embodiments of the present application and the features in the embodiments can be combined with each other.

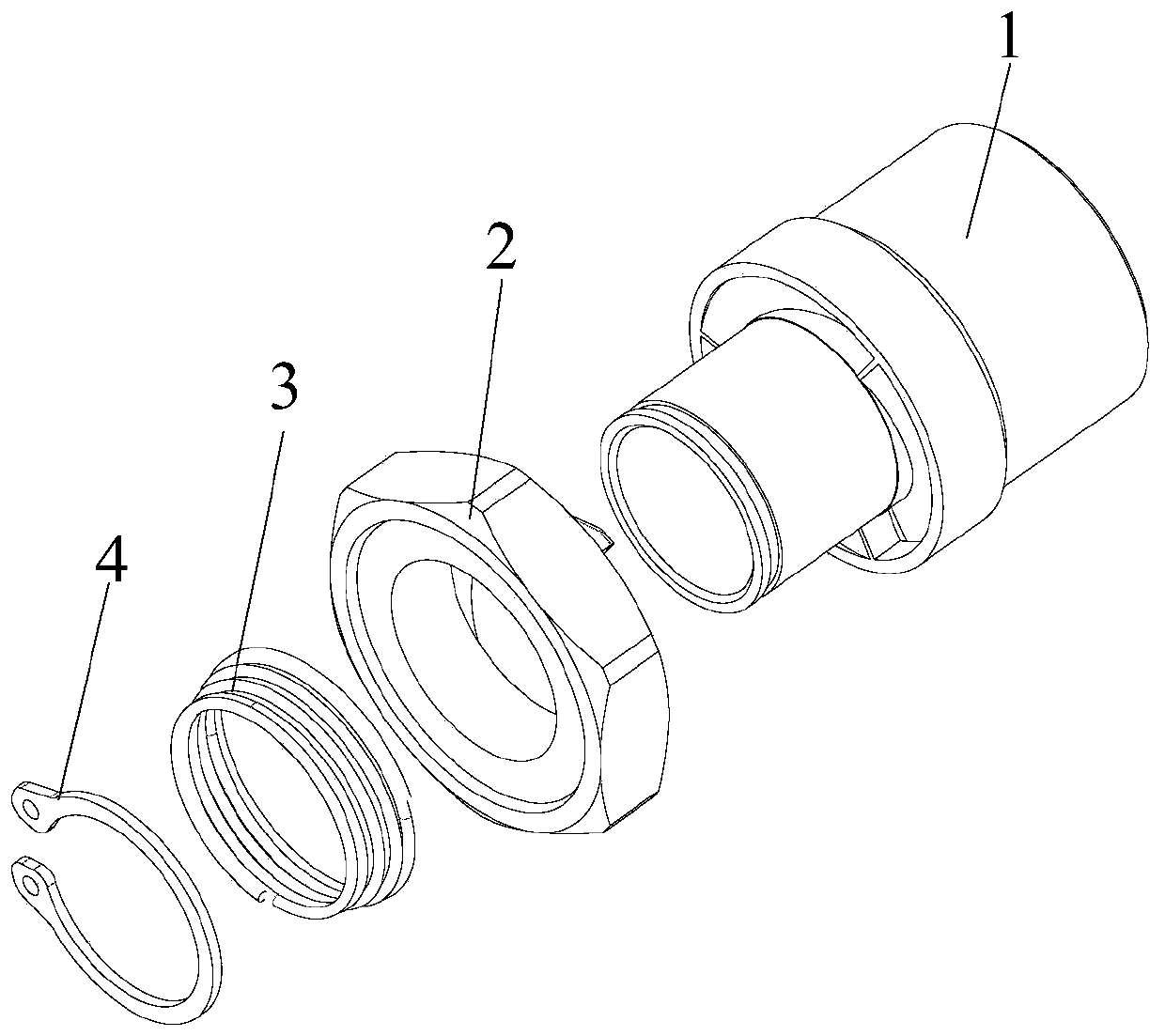

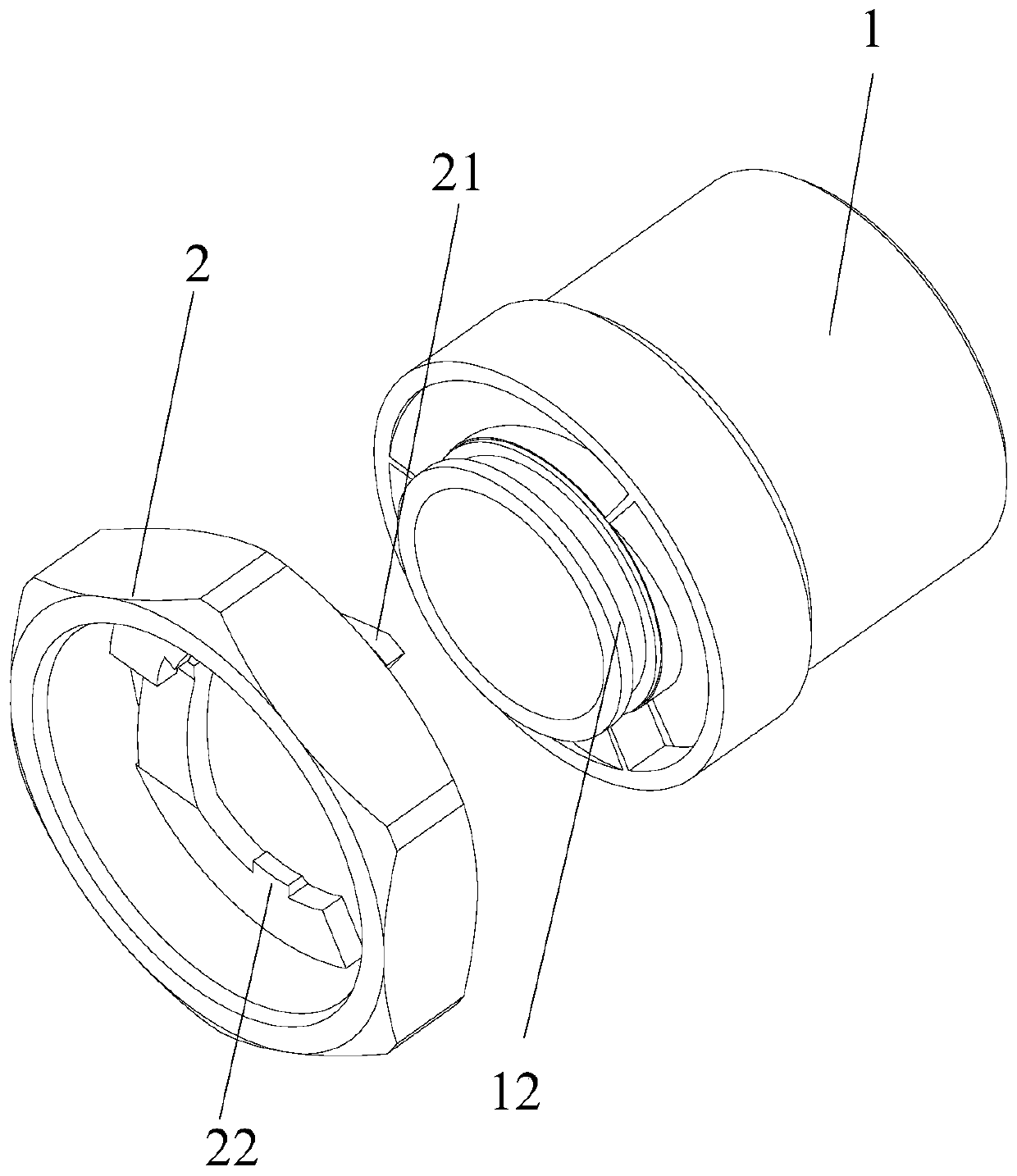

[0034] Such as Figure 2 to Figure 8 As shown, one embodiment of the present invention provides an anti-disassembly union nut assembly, and the anti-disassembly union nut includes a union nut 1, an auxiliary nut 2 and a limiting mechanism;

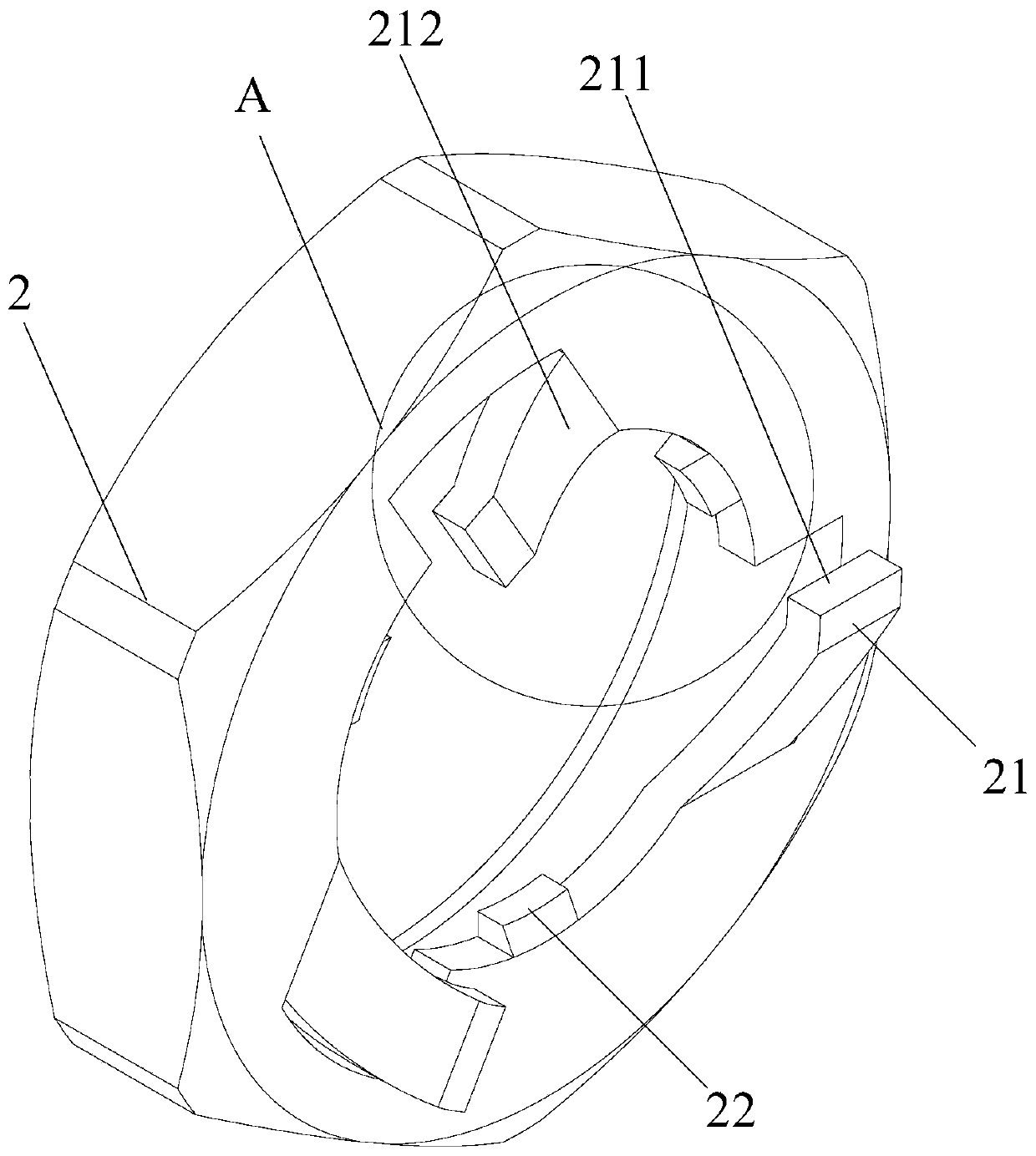

[0035] The auxiliary nut 2 is provided with a plurality of ratchets 21 made of elastic material, one end of the ratchet 21 is connected to the end surface on one side of the auxiliary nut 2, and the other end faces away from the side of the auxiliary nut 2. one side extension;

[0036] Said union nut 1 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com