A kind of hot-melt size for cotton fiber sizing and preparation method thereof

A cotton fiber and pulp technology, which is applied in the field of hot melt pulp preparation, can solve the problems of high hairiness index, low abrasion resistance, low desizing rate, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

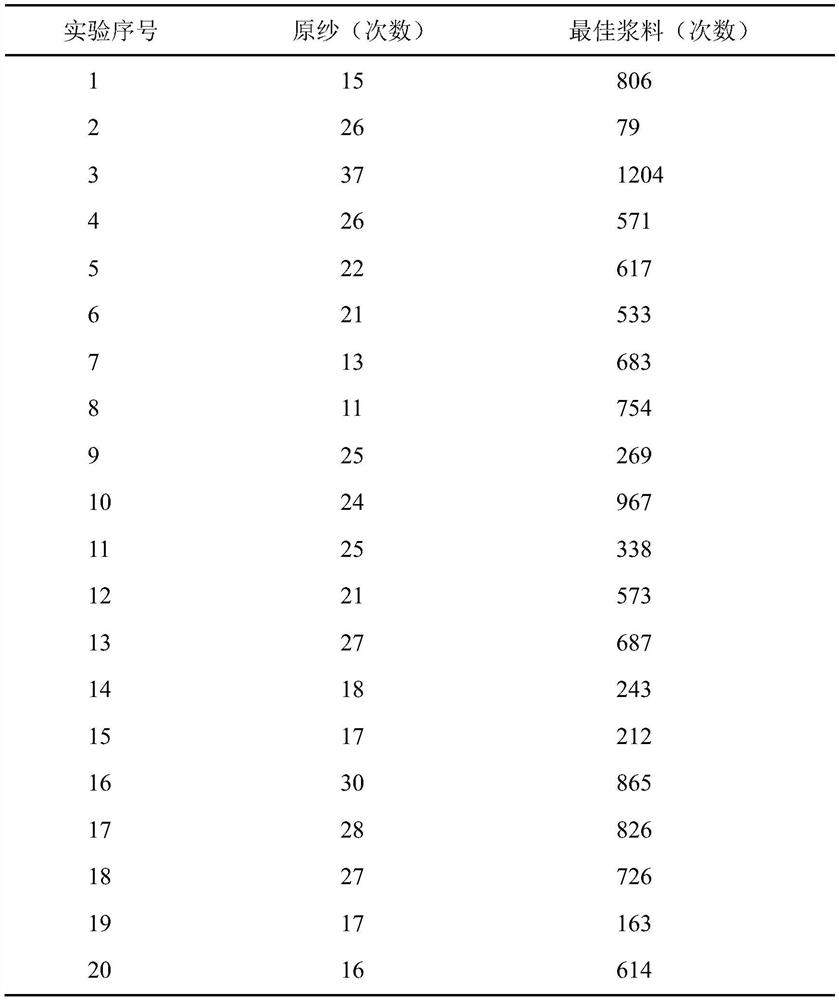

Examples

preparation example Construction

[0032] The present invention also provides a method for preparing hot-melt size for cotton fiber sizing, the specific steps are as follows:

[0033] Step 1. Weigh each raw material according to the mass ratio stipulated in the formula, and mix them in a certain order. Specifically, implement according to the following steps:

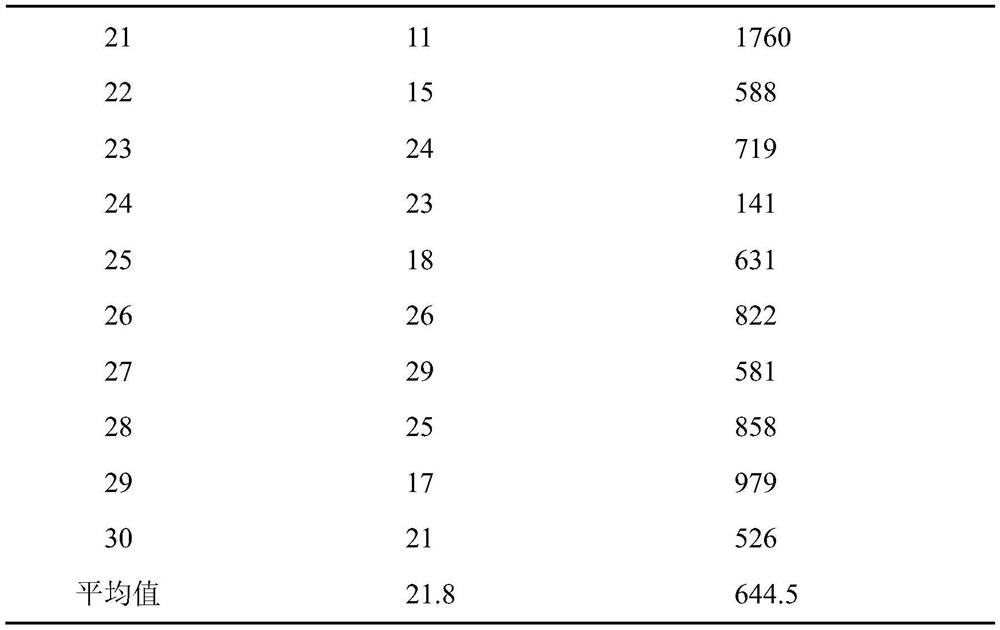

[0034] Step 1.1, weighing 30%-48% behenic acid or arachidic acid or hexadecanoic acid, 10%-20% EVA, 5%-15% EAA, 17% paraffin, 8%- 11% rosin, 7% copovidone, 4%-6% stearic acid, 1% antioxidant;

[0035] In step 1.1, the antioxidant is antioxidant 1076.

[0036] Step 1.2, mix the raw materials weighed in step 1.1 evenly;

[0037] Step 2. Add the raw materials uniformly mixed in step 1.2 into the container while heating and stirring for a certain period of time. After the raw materials are completely melted into a thick slurry, stop heating and stop stirring;

[0038] The heating temperature in step 2 is 140°C-160°C.

[0039] The heating time in step 2 i...

Embodiment 1

[0051] Take by weight 30% behenic acid, 17% EVA, 15% EAA, 17% paraffin, 8% rosin, 7% copovidone, 5% stearic acid, 1% antioxidant 1076, and the weighed raw materials are mixed evenly. Adjust the reaction temperature at 140°C, add the raw materials into the beaker to heat, stir and observe. Heat for twenty-five minutes, and the raw materials are melted evenly. Stop heating, stop stirring, take out the beaker, wait for the slurry to cool naturally, and make the required slurry.

Embodiment 2

[0053] Weighing mass percent is 33% hexadecanoic acid, 18% EVA, 8% EAA, 17% paraffin, 10% rosin, 7% copovidone, 6% stearic acid, 1% Antioxidant 1076, and the weighed raw materials are mixed evenly. Adjust the reaction temperature at 150°C, add the raw materials into the beaker to heat, stir and observe. Heat for 15 minutes, the raw materials are melted evenly. Stop heating, stop stirring, take out the beaker, wait for the slurry to cool naturally, and make the required slurry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com