A kind of refrigerator polyurethane insulation layer and preparation method thereof

A polyurethane and insulation layer technology, applied in the field of polyurethane foaming, can solve the problems of low foaming agent addition ratio, difficulty in dissolving foaming agent, and insufficient premixing, so as to improve foaming quality, increase foam strength, and reduce The effect of foaming on the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

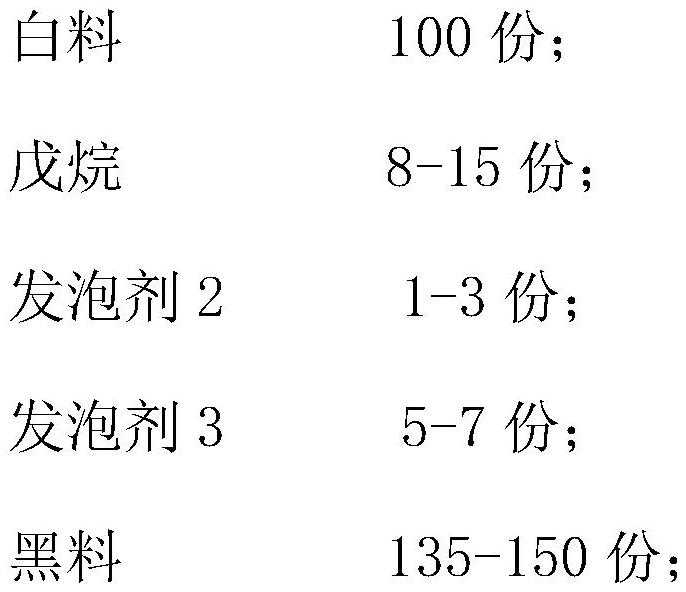

[0023] A method for preparing a refrigerator polyurethane insulation layer of the present invention comprises the following steps:

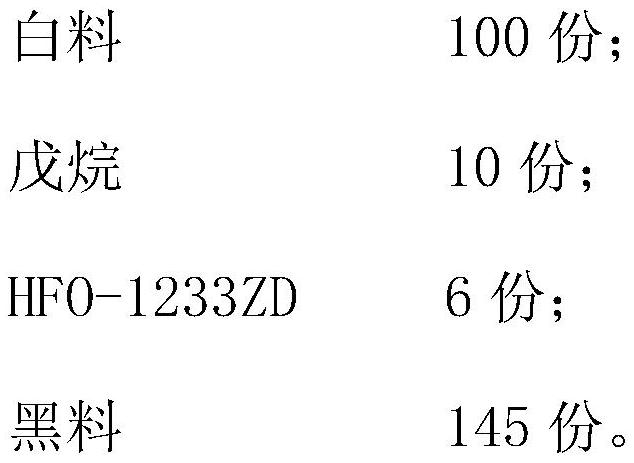

[0024] Step 1: Mix 100 parts of white material, 10 parts of pentane, and 6 parts of HFO-1233ZD in a white material premixing tank according to the weight ratio at a material temperature of 15-25°C to obtain a mixed white material;

[0025] Step 2: Put 145 parts of high-functional polymethylene polyphenylisocyanate with a viscosity of 350-500 (25°C) / mPa·s in the black material premixing tank under the condition of material temperature of 15-25°C Stir evenly to obtain the prepared black material;

[0026] Step 3: At a material temperature of 15-25°C, inject 2.5 parts of R600a into the foaming agent premix tank through high-pressure liquefaction to obtain liquid R600a;

[0027] Step 4: Put the mixed white material, preparatory black material and liquid R600a into the injection gun head, mix well and inject it into the box or door mold to be foamed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com