Preparation method of Sb-doped SnO2 @ carbon nanotube composite electrothermal film

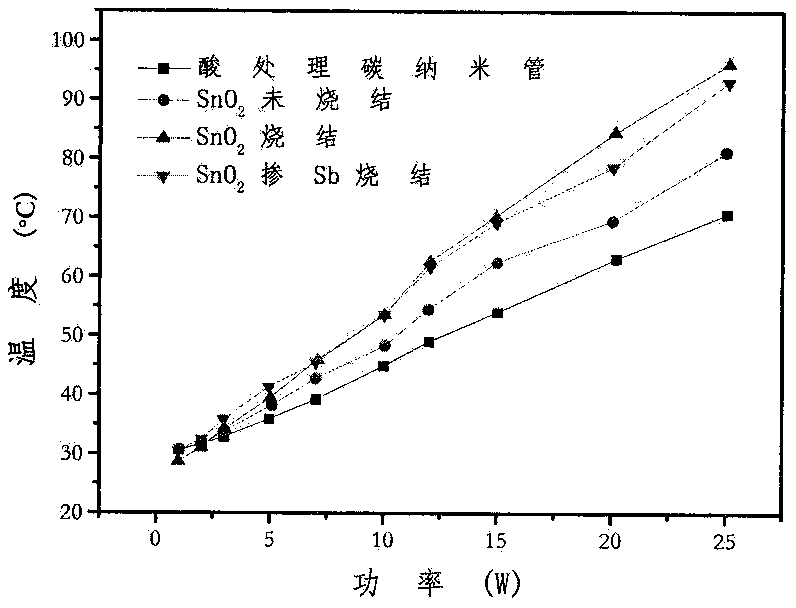

A carbon nanotube composite and carbon nanotube thin film technology, which is applied in the field of electric heating thin film material preparation, can solve the problems of poor long-term stability and low thermal conversion rate of carbon nanotube thin films, improve the heating rate, and overcome the poor flexibility of oxides. , the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

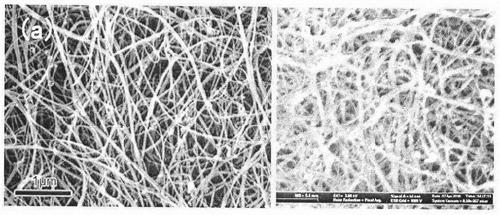

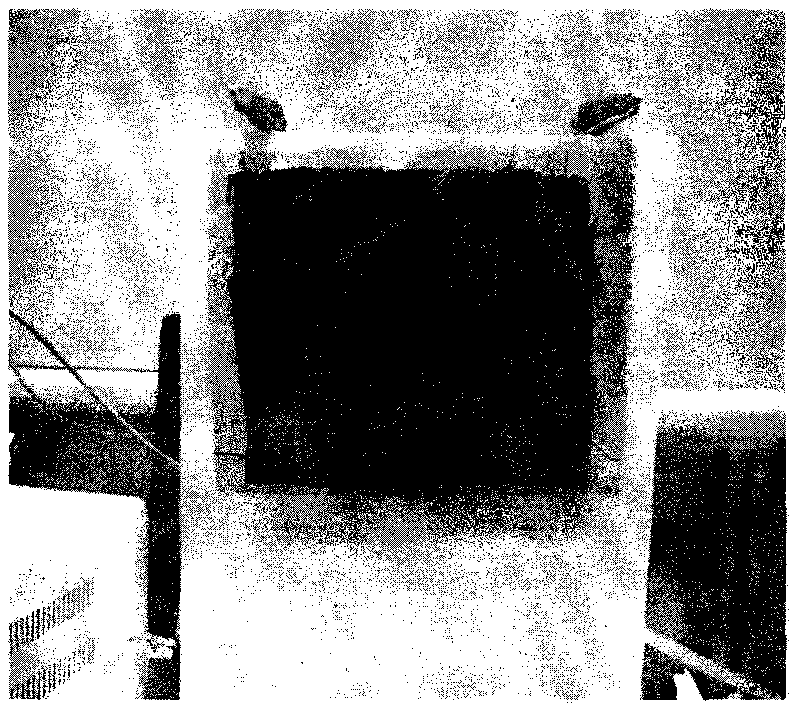

[0022] Divide the area 10×10cm 2 The carbon nanotube film was soaked in dilute hydrochloric acid for 6 hours, rinsed with deionized water and ethanol respectively, then soaked in concentrated nitric acid for 6 hours, rinsed with deionized water and ethanol again, and placed in an oven at a constant temperature of 60°C. drying to obtain a two-step acid-treated carbon nanotube film sample.

Embodiment 2

[0024] On the basis of Example 1, the two-step acid-treated film was immersed in SnCl 4 , NaOH and SbCl 3 In the mixed reaction solution, the solvent is a mixture of deionized water and ethanol, and it is hydrothermally heated in a 150°C reactor, washed and dried; finally, the dried film is placed in a tube furnace, under an inert gas N 2 Under protection, the temperature was raised to 500°C at a rate of 5°C / min for sintering for 20 minutes, and the film was taken out after cooling down to obtain the final product antimony-doped SnO 2 @Carbon nanotube composite electrothermal film material.

Embodiment 3

[0026] SnCl 4 , NaOH and SbCl 3 SbCl in the mixed reaction solution of 3 Remove, other conditions are identical with embodiment 2, obtain SnO 2 @Carbon nanotube composite membrane material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com