High air tightness type air closer

An air-closing, high-air-tight technology, applied in conveyors, transportation and packaging, conveying bulk materials, etc., can solve the problems of limited area for installing sealing devices, and the sealing degree of rotating impellers cannot reach high air-tight conveying materials, etc. Achieving good dynamic sealing effect, increasing the area and reducing the diameter of the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Below in conjunction with accompanying drawing and embodiment the invention is further described:

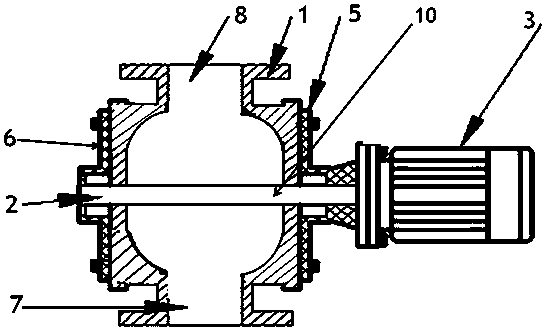

[0061] Such as figure 1 , figure 2 The shown high airtight air locker includes a valve body 1 , a rotating impeller 2 and a motor 3 .

[0062] The valve body 1 has a feed port 8 and a discharge port 7 up and down.

[0063] Both sides of described valve body 1 have front side cover 6, rear side cover 5.

[0064] The motor 3 is fixed on the rear side cover 5 of the valve body 1 .

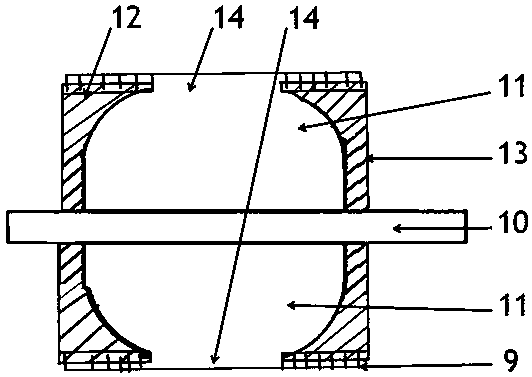

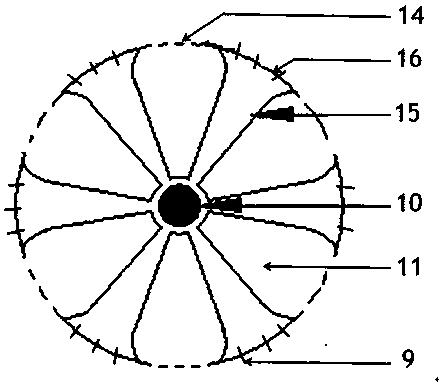

[0065] Such as figure 1 , figure 2 , image 3 The illustrated rotary impeller 2 includes a partition 15 , a sealing plate 12 , a side plate 13 , a drive shaft 10 , and a sealing device 9 .

[0066] The rotary impeller 2 is installed inside the valve body 1 .

[0067] One end of the transmission shaft 10 of the rotary impeller 2 is fixed in the bearing at the center position of the front side cover 6 , and the other end of the transmission shaft 10 passes through the bearing at the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com