Self-loading self-unloading ship and ship loading and ship unloading method thereof

A self-unloading and self-loading technology, applied in loading/unloading, cargo handling equipment, measuring devices, etc., can solve the problems of functional limitations, single loading and transportation functions, etc., and achieve the effect of accurate weight measurement and accurate dynamic measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

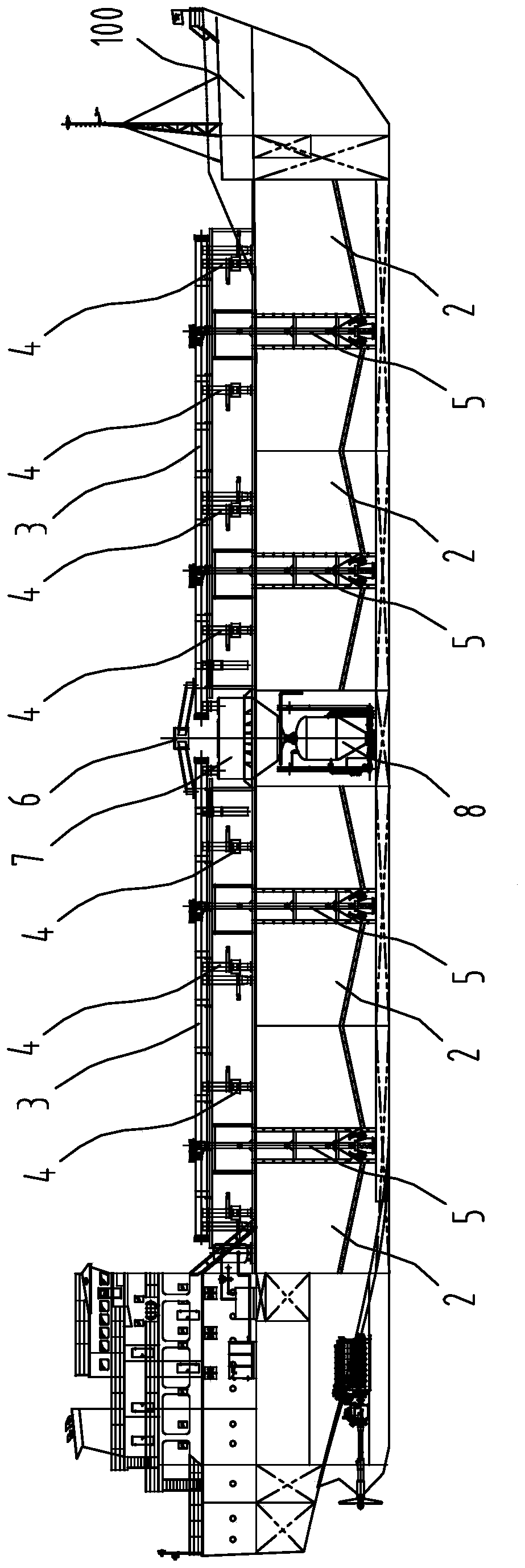

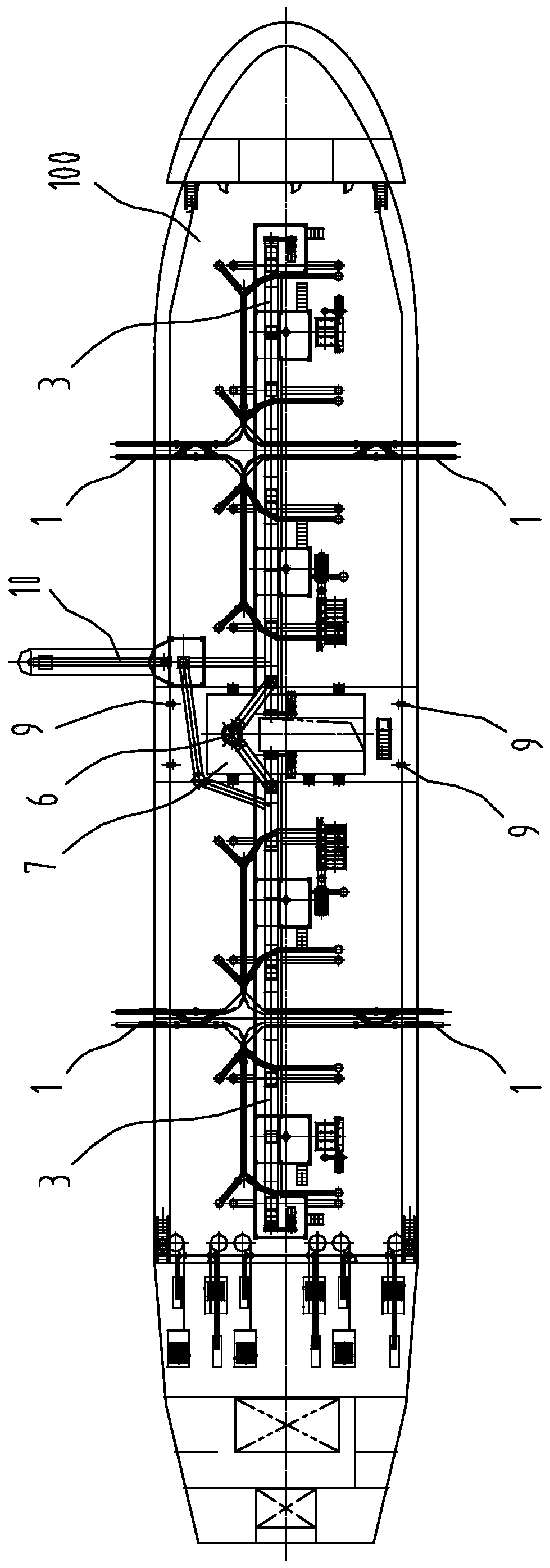

[0032] Example 1: Please refer to Figure 1-17 As shown, a preferred embodiment of the self-loading and self-unloading ship of the present invention includes a hull 100, a pneumatic feeding pipe 1, a horizontal screw conveyor 3, a cloth chute 4, a vertical screw conveyor 5, a hopper 6, a buffer warehouse 7, Measuring chamber 8, metering buffer chamber 78 is set in the middle of the hull 100, and several cabins 2 are arranged at intervals through partitions on both sides of the metering buffer chamber 78 in the hull 100, and several groups of metering chambers arranged side by side are arranged in the lower part of the metering buffer chamber 78. Storehouse 8, the buffer storehouse 7 is placed above each metering storehouse 8, vertical screw conveyors 5 are arranged longitudinally in the middle of each cabin 2, and horizontal screw conveyors are respectively arranged horizontally above each cabin 2 on both sides of the upper end of the buffer storehouse 7 The machine 3 and the ...

Embodiment 2

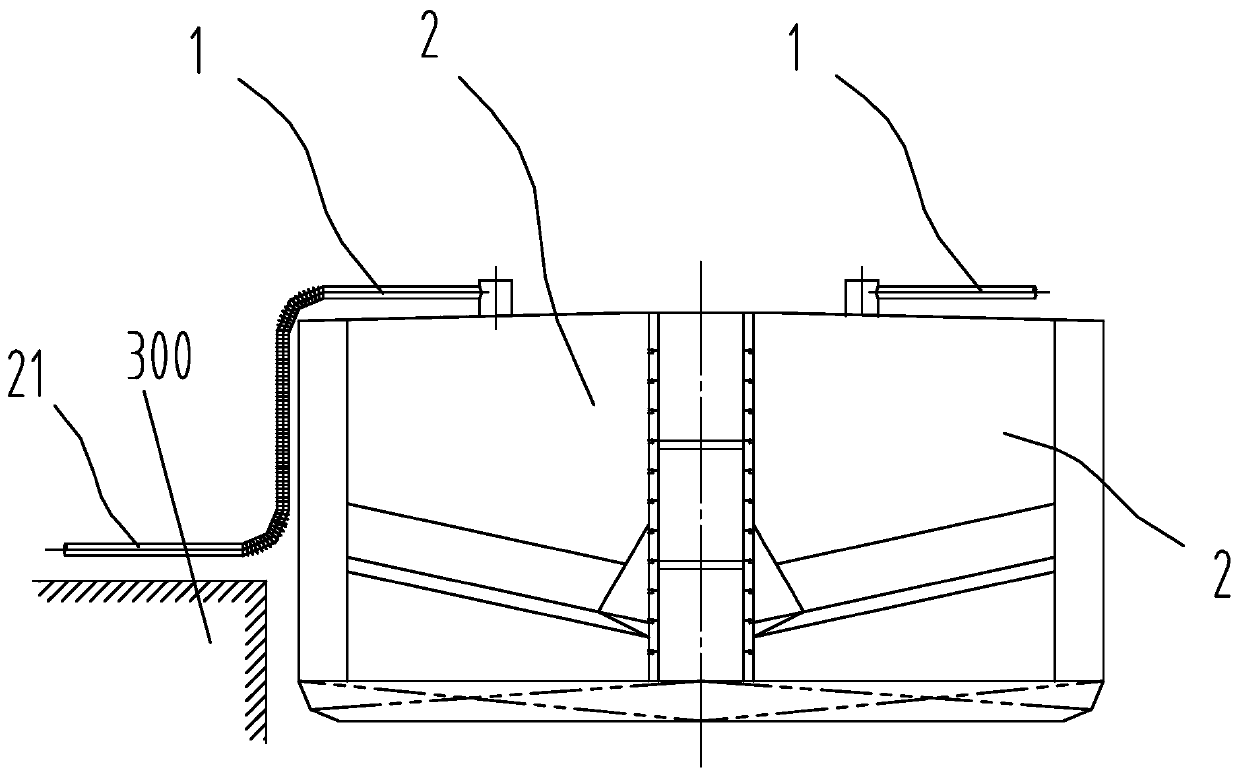

[0035] Example 2: Please refer to image 3 , Figure 4 Shown, on the basis of embodiment 1, a kind of wharf pneumatic loading method that adopts described self-loading and self-unloading ship, bulk material passes through the screw pump on the wharf 300, through the wharf pneumatic feeding pipe 21 and the corresponding cabin 2 After the pneumatic feeding pipe 1 is docked, it is input into the corresponding cabin 2.

Embodiment 3

[0036] Example 3: Please refer to Figure 5 ~ Figure 7 Shown, on the basis of embodiment 1, a kind of wharf mechanical loading method that adopts described self-loading and self-unloading ship, wharf 300 is provided with mechanical type shiploader 33, bulk material passes through mechanical type shiploader 33 And the telescopic chute 32 is delivered to the receiving hopper 6, and then the receiving hopper 6 is delivered to the horizontal screw conveyor 3 through the material distribution chute 31, and is delivered to the corresponding cabin 2 by the horizontal screw conveyor 3 through the distribution chute 4. Wherein said mechanical ship loader 33 adopts such as patent publication number is CN104477672A, a kind of environment-friendly linear mobile ship loader, it comprises door frame, column, turntable, arm frame, telescopic chute, conveyor belt conveyor, counterweight Frame, dustproof device and cart traveling mechanism, wherein, the telescopic chute adopts a dustproof doub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com