Composite material rail side signal equipment ground hardening device and installation method thereof

A technology of ground hardening and signal equipment, which is applied in the direction of railway signal and safety, railway signal, vehicle route interaction equipment, etc., can solve the problems of destroying railway line appearance, high comprehensive cost, station pollution, etc., to ensure driving safety, install Simple and convenient, fast construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

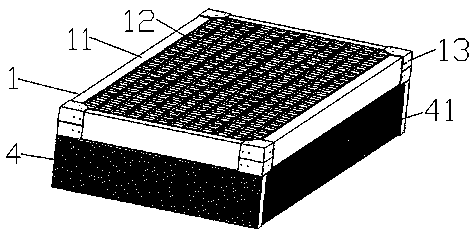

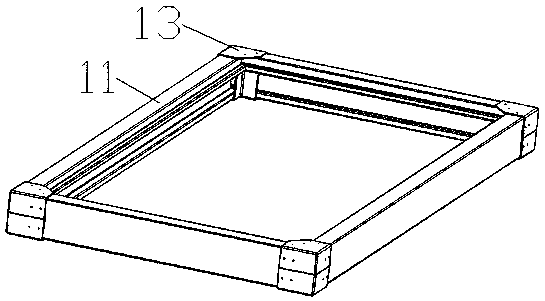

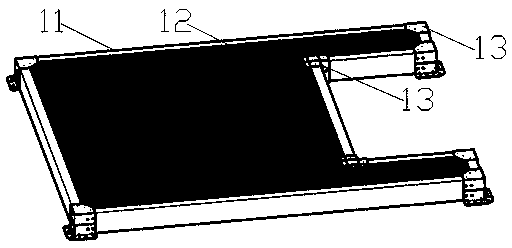

[0039] The ground hardening of a kind of composite material wayside signal equipment provided by the present invention includes an upper plane 1, and the upper plane includes an upper plane frame 11 and several hardened surface panels 12; several said hardened surface panels 12 are installed and fixed on 11 on the upper plane frame, which is fixedly connected with the upper plane frame 11 with the wrap angle 13 by self-tapping screws or rivets 2; On the same horizontal plane; the adjacent hardened panels 12 are fixedly connected by self-tapping screws or rivets 2, connecting pieces 4 and cross pan head screws.

[0040] Specifically, the upper plane frame 11 is a rectangle, such as figure 2 shown; or concave (for turnouts), such as image 3 shown. Two adjacent frames are fixedly connected by wrap angle 13, such as Figure 4 As shown; the side top surface of the wrap angle 13 is fastened and connected with self-tapping screws or rivets 2; several crosspieces 72 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com