Full-automatic honeycomb aluminum cutting machine

An aluminum cutting machine, fully automatic technology, applied in the direction of metal sawing equipment, sawing machine, metal processing equipment, etc., can solve the adverse effects on the health of personnel in the working environment, the unfavorable control of the accuracy of processed plates, and the increase in labor costs, etc. problems, to achieve the effect of ensuring the controllability of processing, improving the pass rate of processing, and realizing the automatic control of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

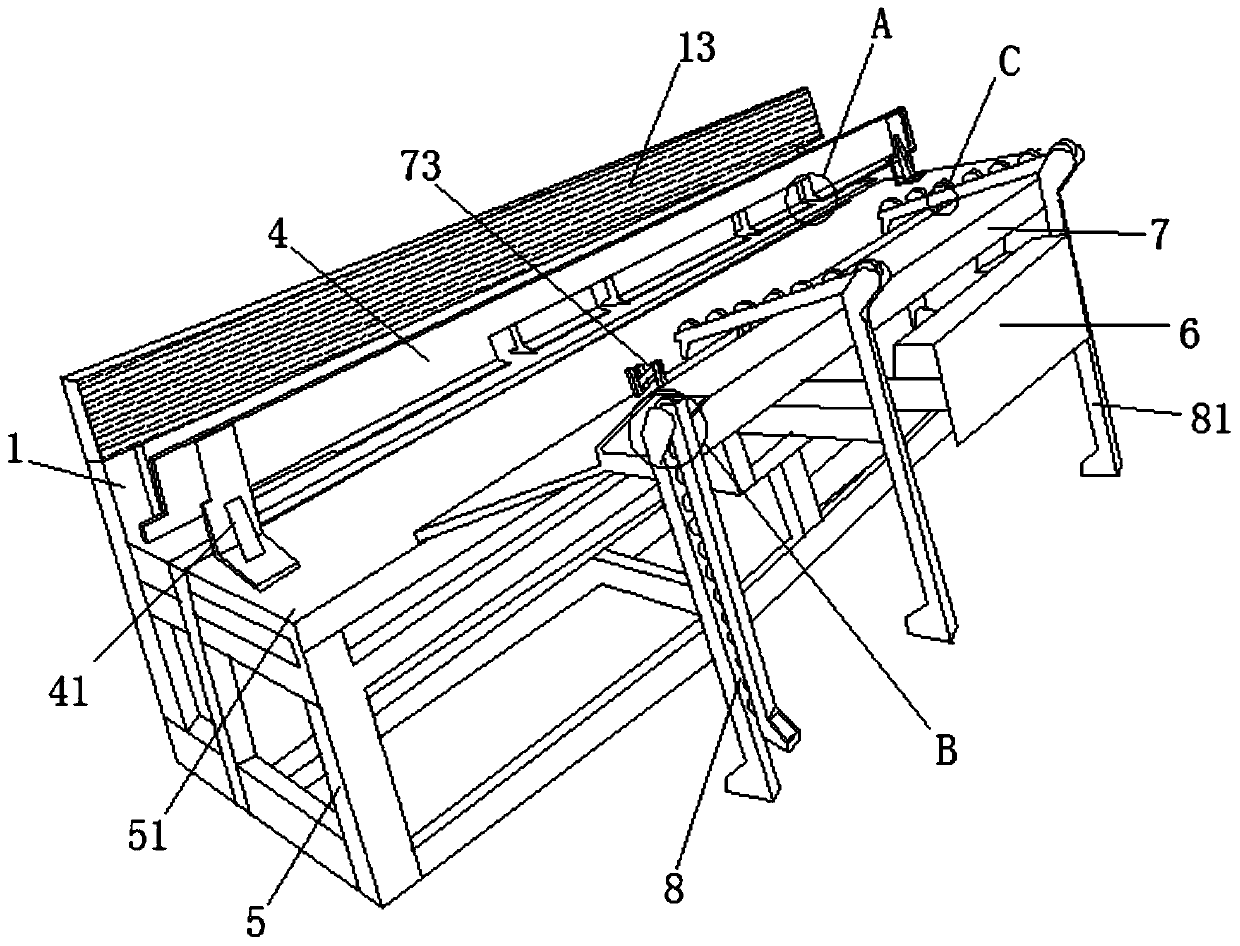

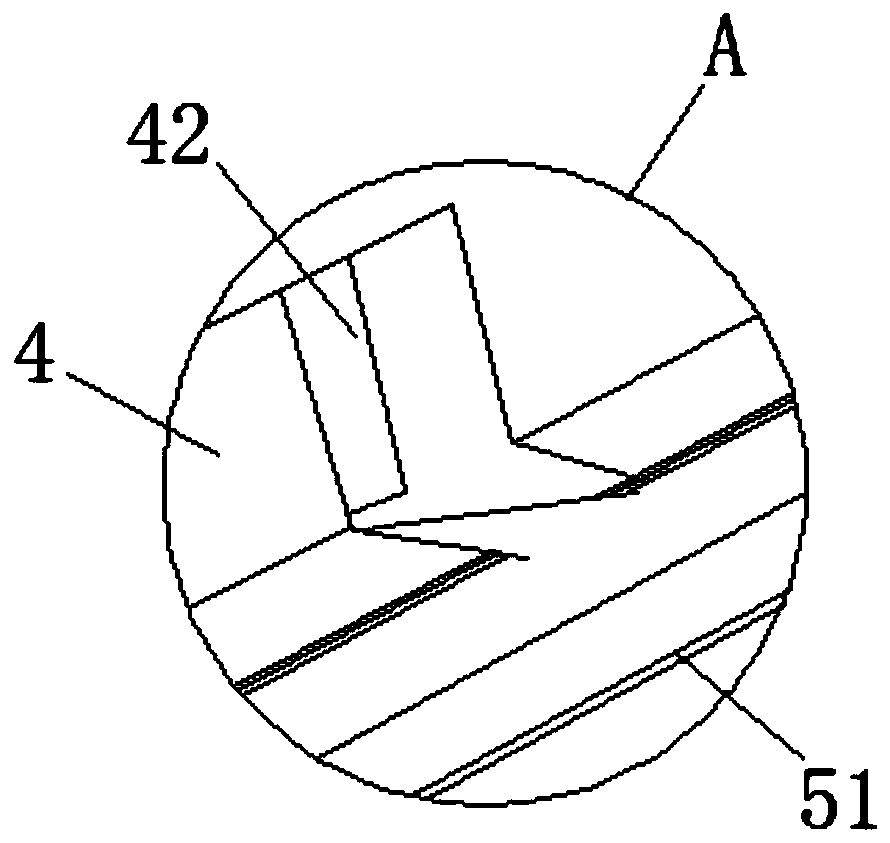

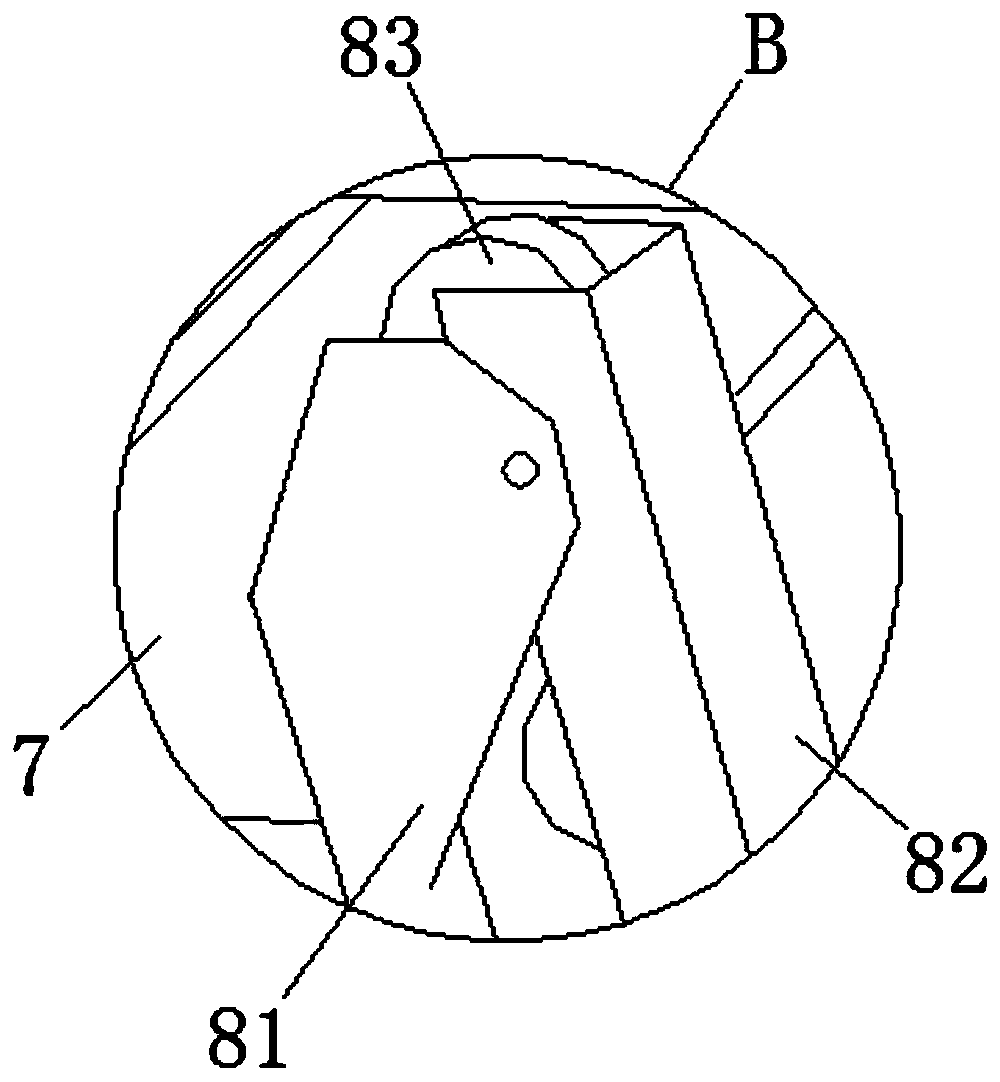

[0036] The structure of the aluminum cutting machine is as follows figure 1 As shown, it includes an aluminum cutting machine frame 1, an automatic feeder, a cylinder pressure beam 4, a saw blade processing head and a numerical control device provided with a control panel. The numerical control device is respectively connected with the aluminum cutting machine frame 1, the automatic feeder, the cylinder pressure beam 4 and the saw blade processing head, and then the processing coefficient is adjusted through the control panel, so as to realize the automatic regulation of the device and improve the processing quality of the product. Guarantees are provided. The aluminum cutting machine rack 1 as Figure 5 As shown, it includes a work panel 12, a drive positioning beam 13 and a processing head drive member. The aluminum cutting machine frame 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com