Polishing apparatus

A technology of grinding device and grinding pad, applied in grinding device, grinding machine tool, grinding workpiece support, etc., can solve problems such as uneconomical and spread of slurry, and achieve the effect of restraining the consumption of slurry and restraining consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

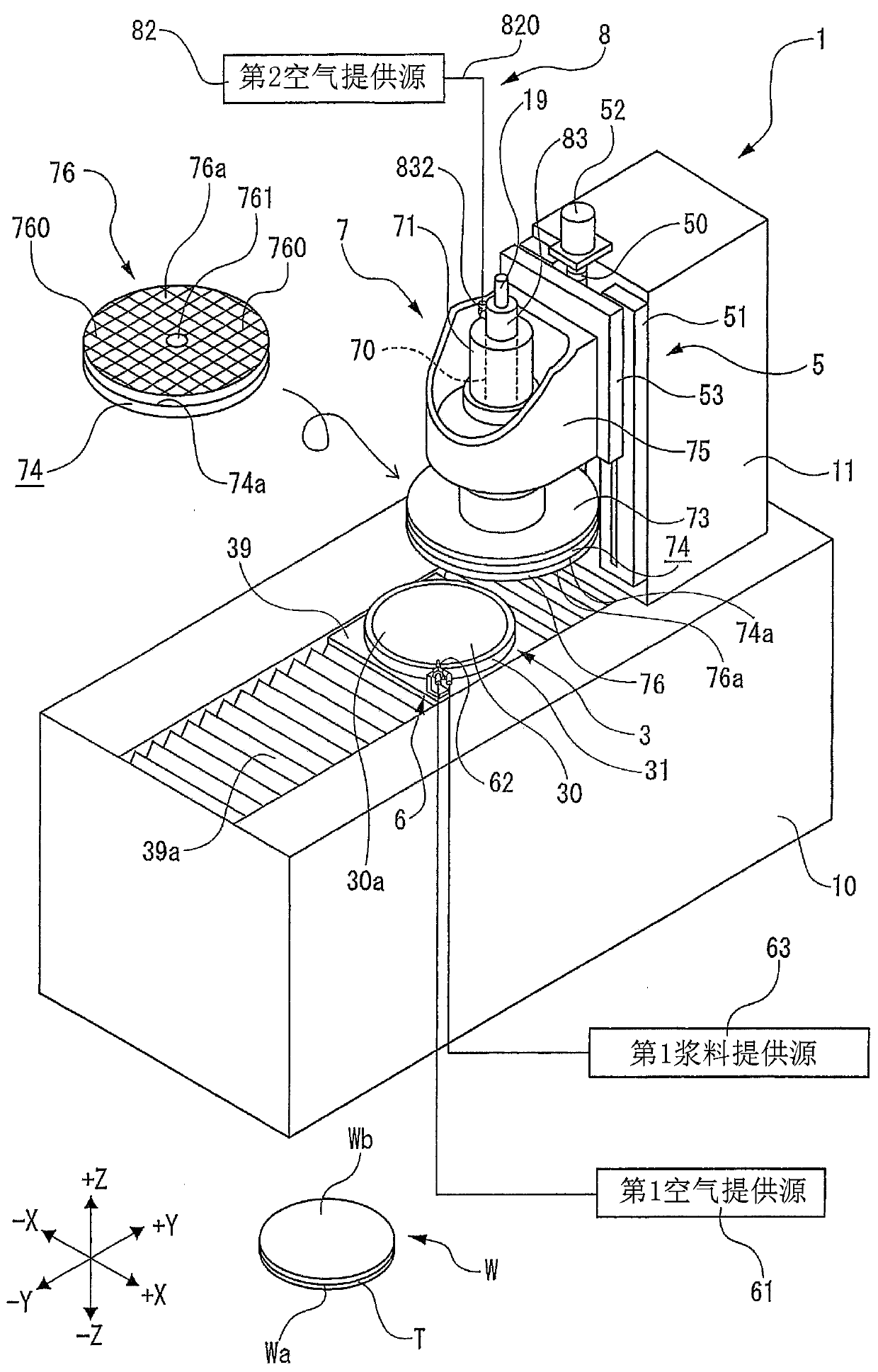

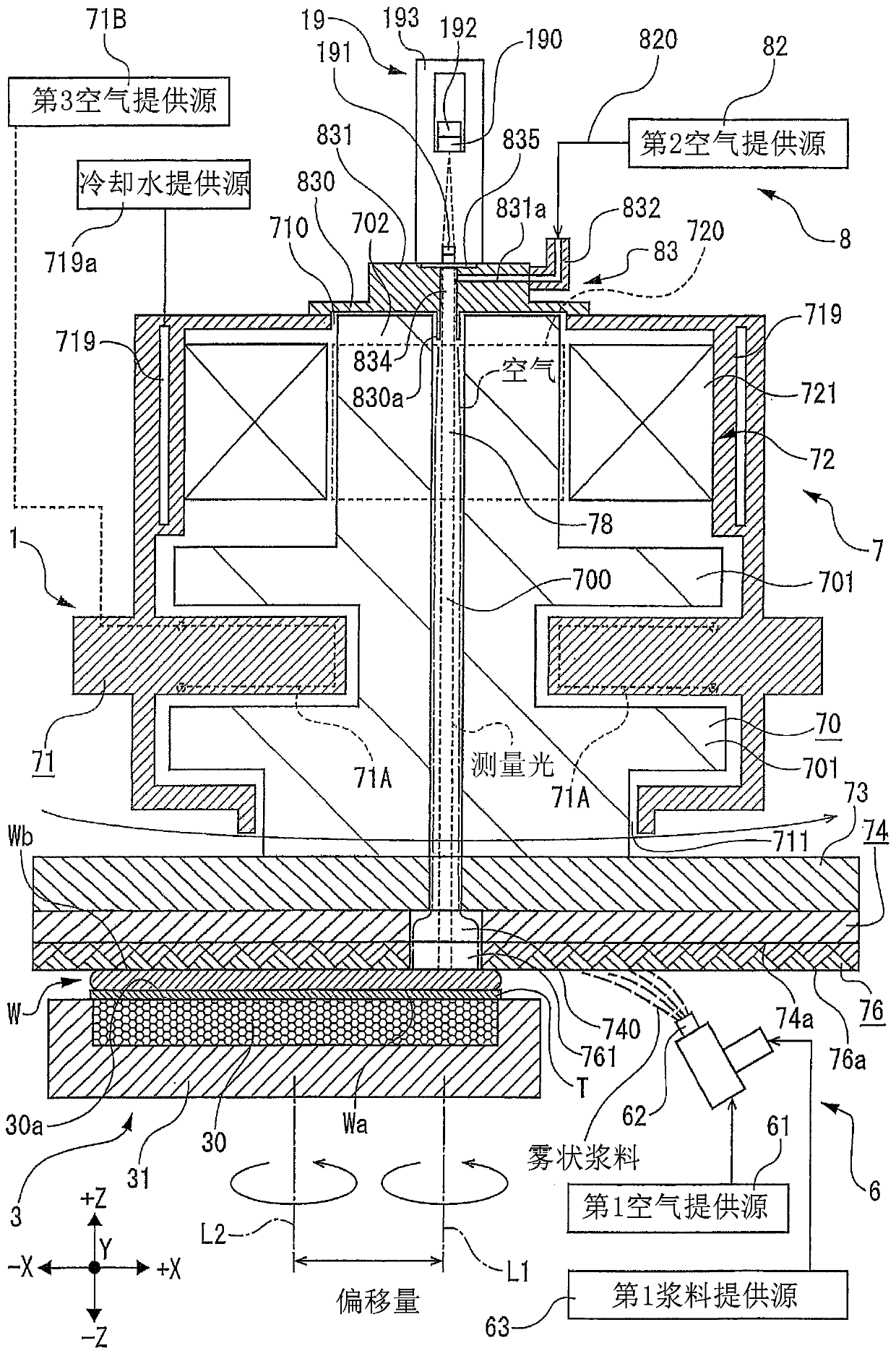

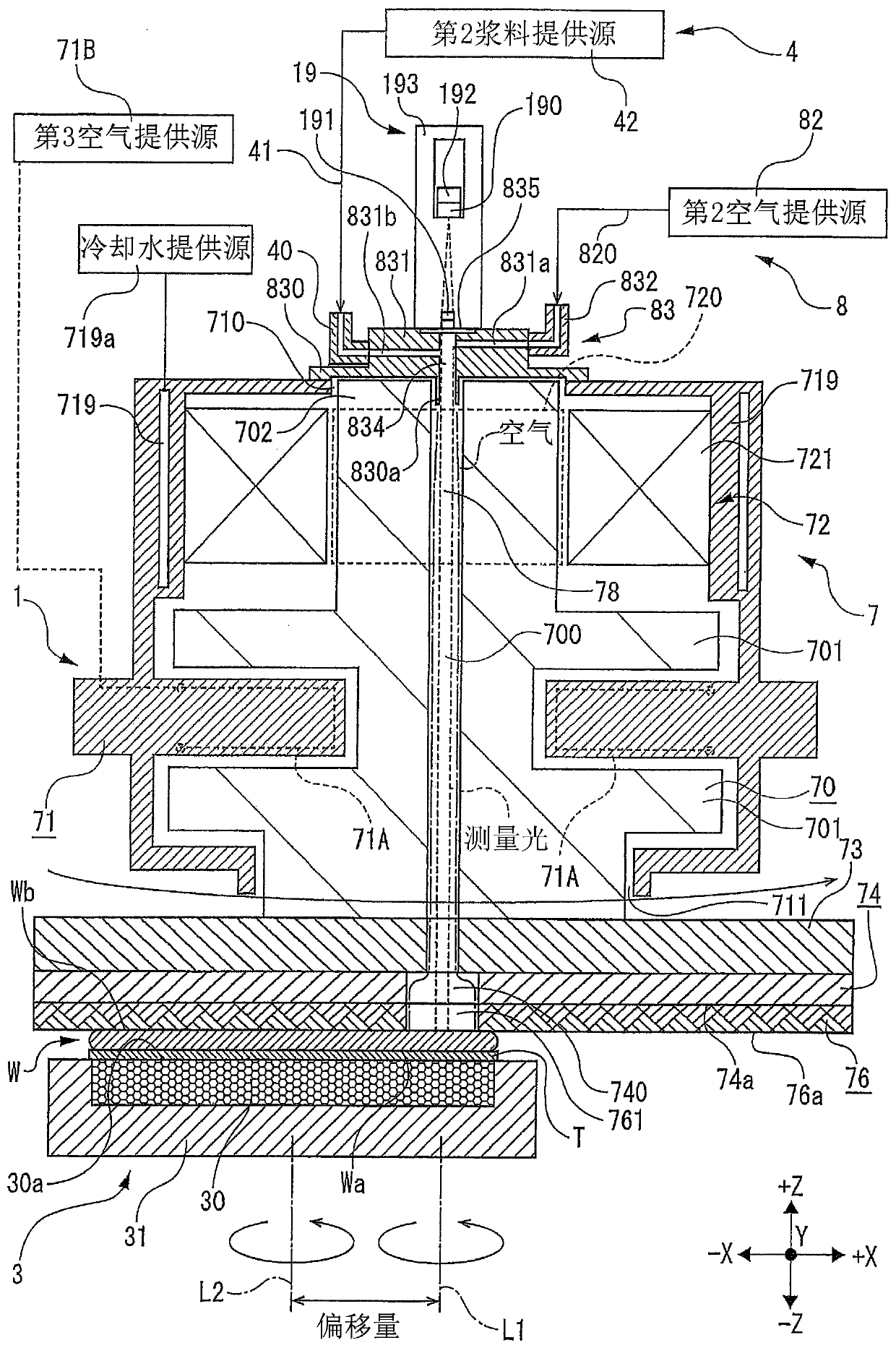

[0018] figure 1 The illustrated polishing device 1 is a device for polishing a wafer W held on a holding table 3 by using a polishing pad 76 attached to a spindle 70 having an axis in the vertical direction (Z-axis direction). : a device base 10 extending in the Y-axis direction; and a column 11 erected on the rear side of the device base 10 in the Y-axis direction.

[0019] figure 1 The wafer W shown is, for example, a circular plate-shaped semiconductor wafer made of silicon or the like. figure 1 Among them, the upper surface Wb facing upward becomes the surface to be polished. exist figure 1 Among them, for example, a plurality of devices are formed on the lower surface Wa of the wafer W facing downward, and the plurality of devices are protected by sticking a protective tape T thereon. In addition, the wafer W is not limited to the example shown in this embodiment.

[0020] The diameter of the wafer W is, for example, 300 mm or 200 mm.

[0021] The holding table 3 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com