Empty bucket flushing device and cleaning method thereof

A flushing device and empty bucket technology, which is applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as unclean cleaning, slow cleaning efficiency, and large space occupied by equipment, so as to improve stability and reliability , cleaning inside the barrel, reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

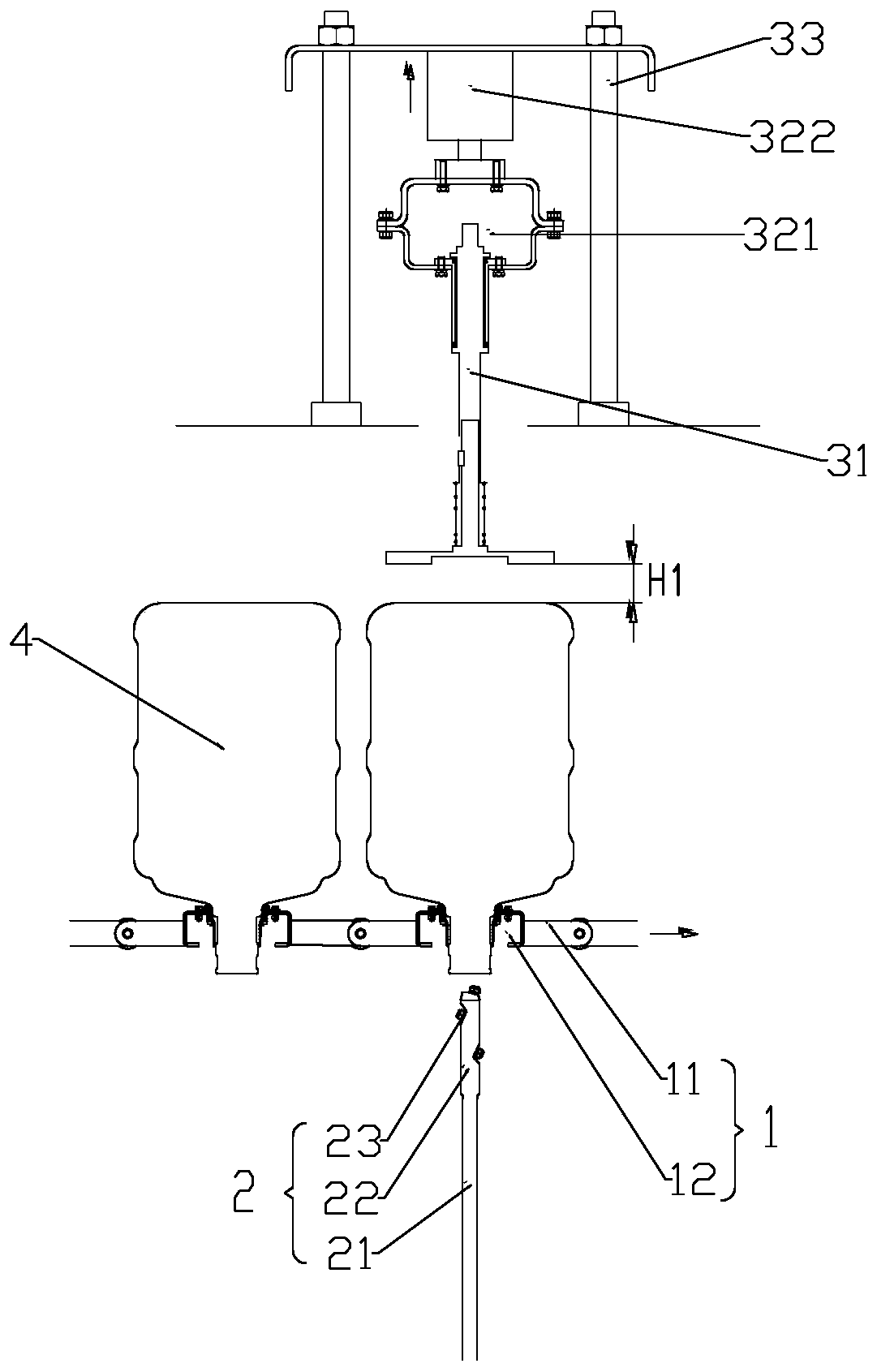

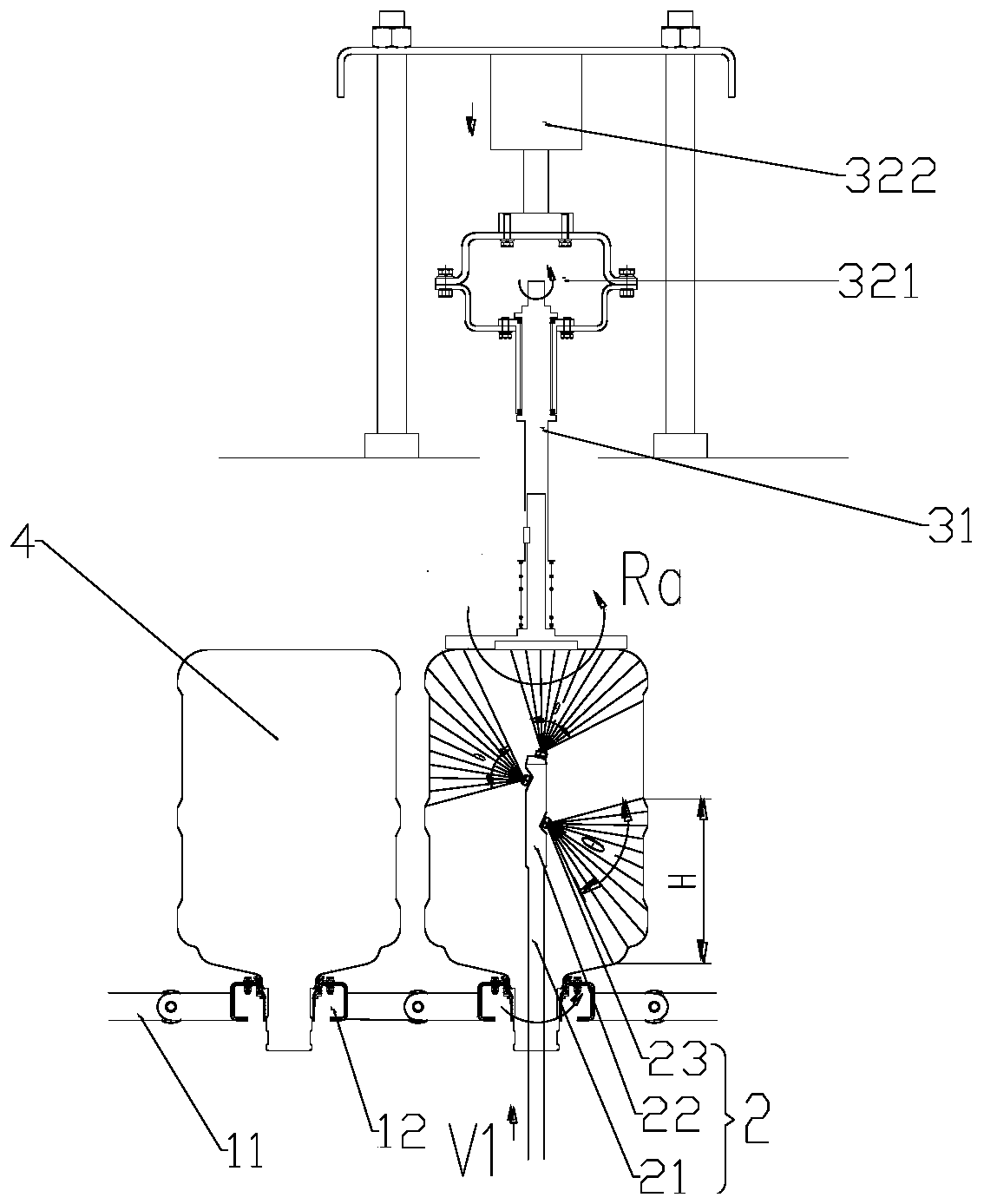

[0026] Refer to figure 1 , figure 2 , image 3 as well as Figure 4 This embodiment provides an empty barrel flushing device, which includes a barrel chain assembly 1, a predetermined number of lifting jet flush assemblies 2 and a barrel pressing rotating assembly 3.

[0027] Refer to figure 1 The bucket chain assembly 1 includes a bucket chain 11 and a predetermined number of bucket mouth rotating seats 12 arranged on the bucket chain 11. The barrel chain 11 is used to transport empty bottles to the cleaning position, forming an industrial assembly line. The barrel mouth rotating seat 12 facilitates the upside-down fixing and rotation of the empty barrel 4 when the empty barrel 4 is cleaned.

[0028] Refer to figure 1 , The lifting jet flushing assembly 2 is provided below the walking chain assembly 1 and includes a lifting mechanism, a jet flushing pipe 21, a jetting punch 22 mounted on the jet flushing pipe 21, and At least three high-pressure nozzles 23 on the jetting head 22...

Embodiment 2

[0044] Refer to Figure 7 This embodiment 2 is substantially the same as embodiment 1, and the difference is that the structure of the rotating seat 31 is different. In this embodiment, the rotating seat 31 includes a fixed seat 311, a rotating shaft 312, and a The barrel pressing block 314, the fixing seat 311 is installed on the lifting frame 321, the rotating shaft 312 is rotatably arranged in the fixing seat 311, and the barrel pressing block 314 and the rotating shaft 312 are away from the lifting frame 321. One end of the frame 321 is connected. A connecting shaft 3141 extends upward on the side of the barrel pressing block 314 away from the empty barrel 4, and an end of the rotating shaft 312 away from the lifting frame 321 defines an assembly hole along the axial direction of the rotating shaft 312. The connecting shaft 3141 is arranged in the assembling hole, the side wall of the rotating shaft 312 is provided with a guide groove 316 in the axial direction correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com