Connecting component for communicating battery pack with load

A technology for connecting parts and battery packs, which is applied in the direction of battery pack parts, conductive connections, conductive connections, etc. It can solve problems that affect the normal use of battery packs, leakage or poor contact, and affect research and development progress, so as to meet the safety requirements of electricity use , simple structure, good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

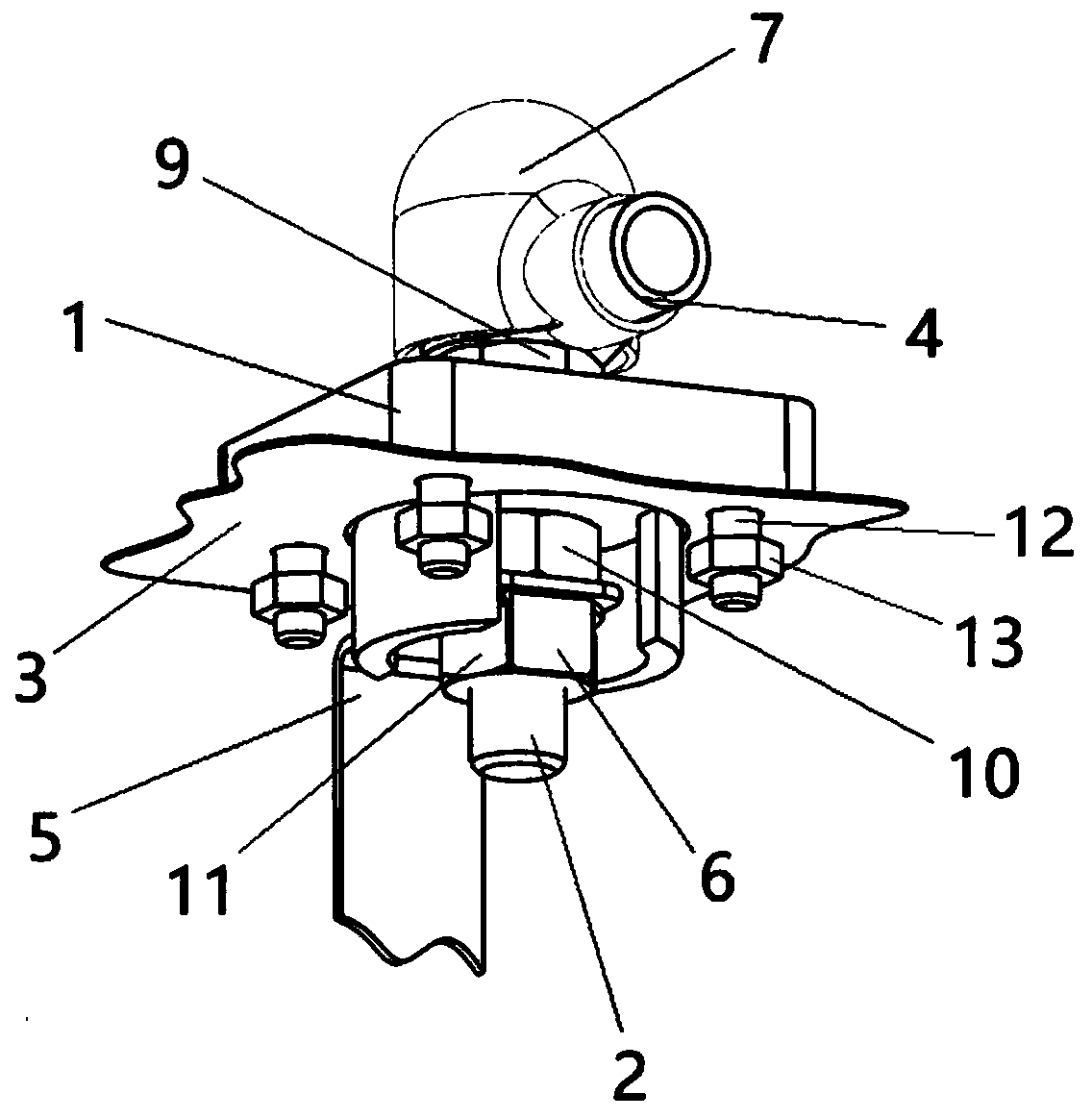

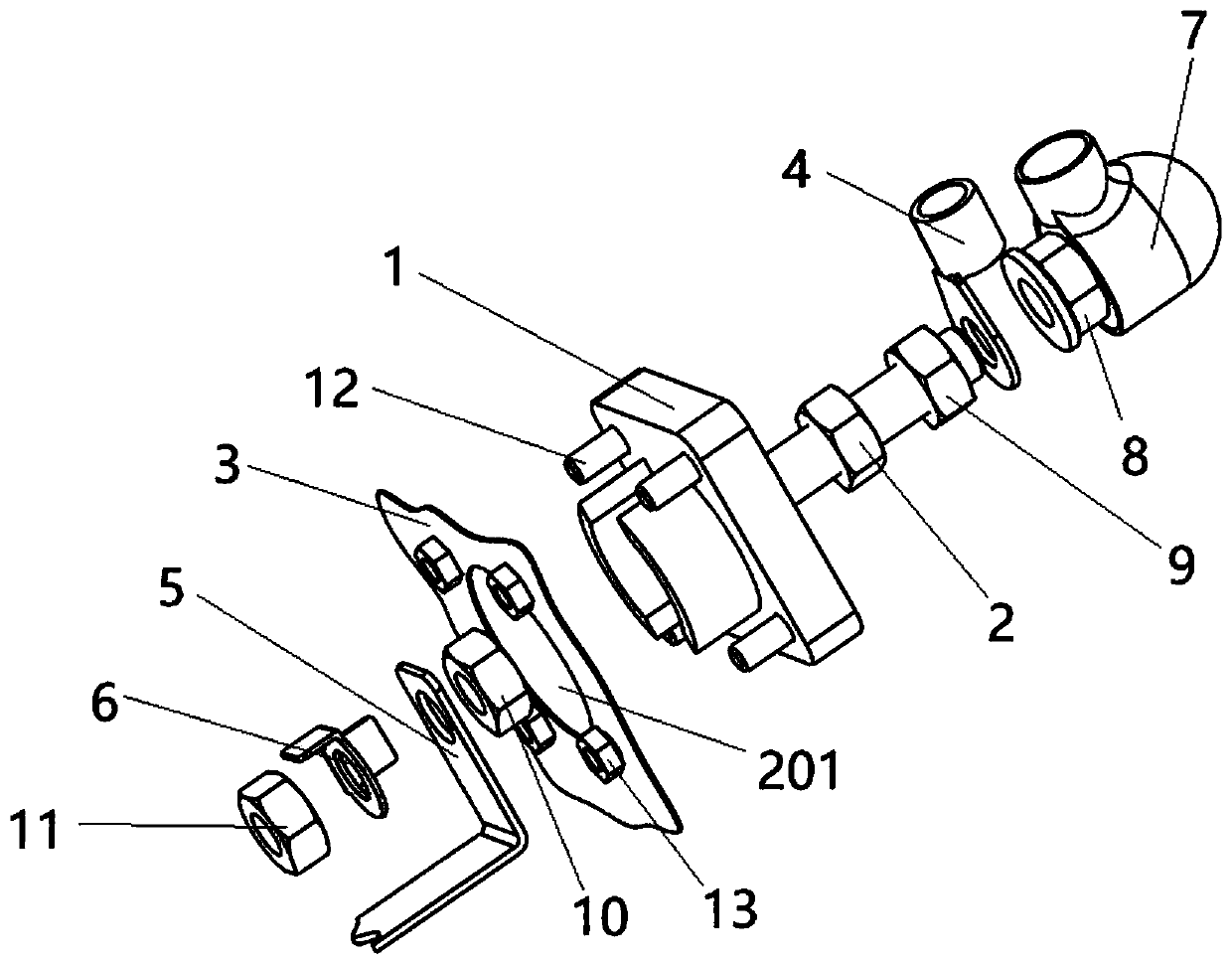

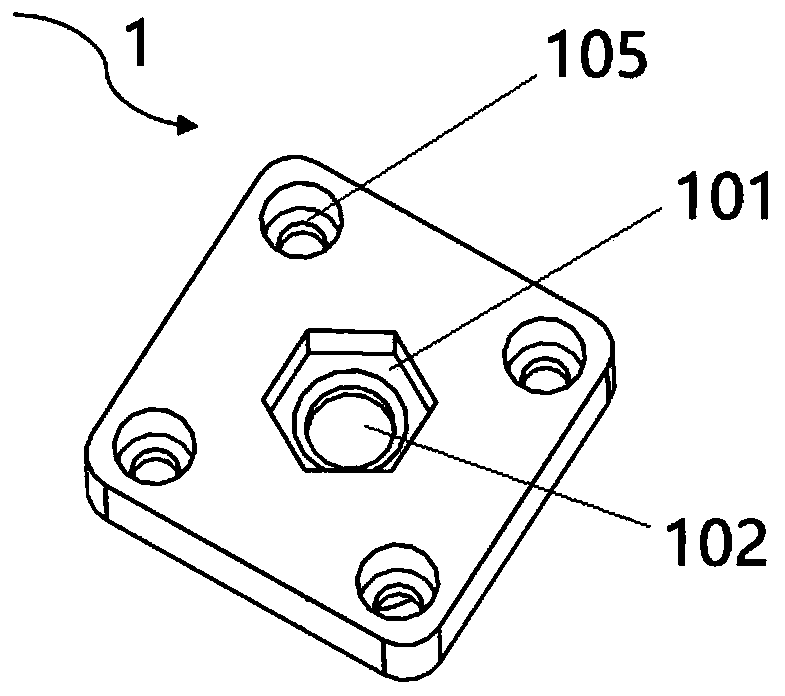

[0021] A connecting part used to connect the battery pack with the load, such as figure 1 , figure 2 As shown, it includes a non-metallic fixed seat 1, a conductive pole 2, a fixed plate 3, a terminal 4, a connecting piece 5, an anti-loosening structural member 6 and a protective cover 7, and the connecting piece 5 of this embodiment is a connecting copper bar; As shown in Fig. 3 (a) and Fig. 3 (b), a groove 101 is provided on one side of the non-metallic fixed seat 1, and a through hole 102 is provided at the bottom of the groove 101, and a through hole 102 is formed on the other side of the non-metallic fixed seat 1. Two half-moon-shaped blocks 103 are arranged symmetrically to the center and a gap 104 is left between the two blocks 103. The height of the blocks 103 of the non-metallic fixed seat 1 is not less than 1.5 times the thickness of the first nut 10, There are stud perforations 105 on the four corners of the non-metallic fixing seat 1; Figure 4 As shown, the con...

Embodiment 2

[0025] A connecting part for connecting the battery pack and the load, its structure is similar to the structure of the connecting part for connecting the battery pack and the load in embodiment 1, the difference is that: the back of the fixing plate (that is, facing away from the non-metallic One side of the fixed seat) is provided with a rivet nut, and the non-metallic fixed seat passes through the stud holes on the non-metallic fixed seat in turn, the threaded hole on the fixed plate, and then cooperates with the rivet nut to lock and fix it. On the fixed plate; the body of the anti-loosening structural part is set on the position where the conductive pole is located between the connecting piece and the first nut through the round hole, and the first baffle plate of the anti-loosening structural part is connected with the outer side of the connecting piece and the second nut in turn. The second baffle plate of the anti-loosening structural member contacts the outer surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com